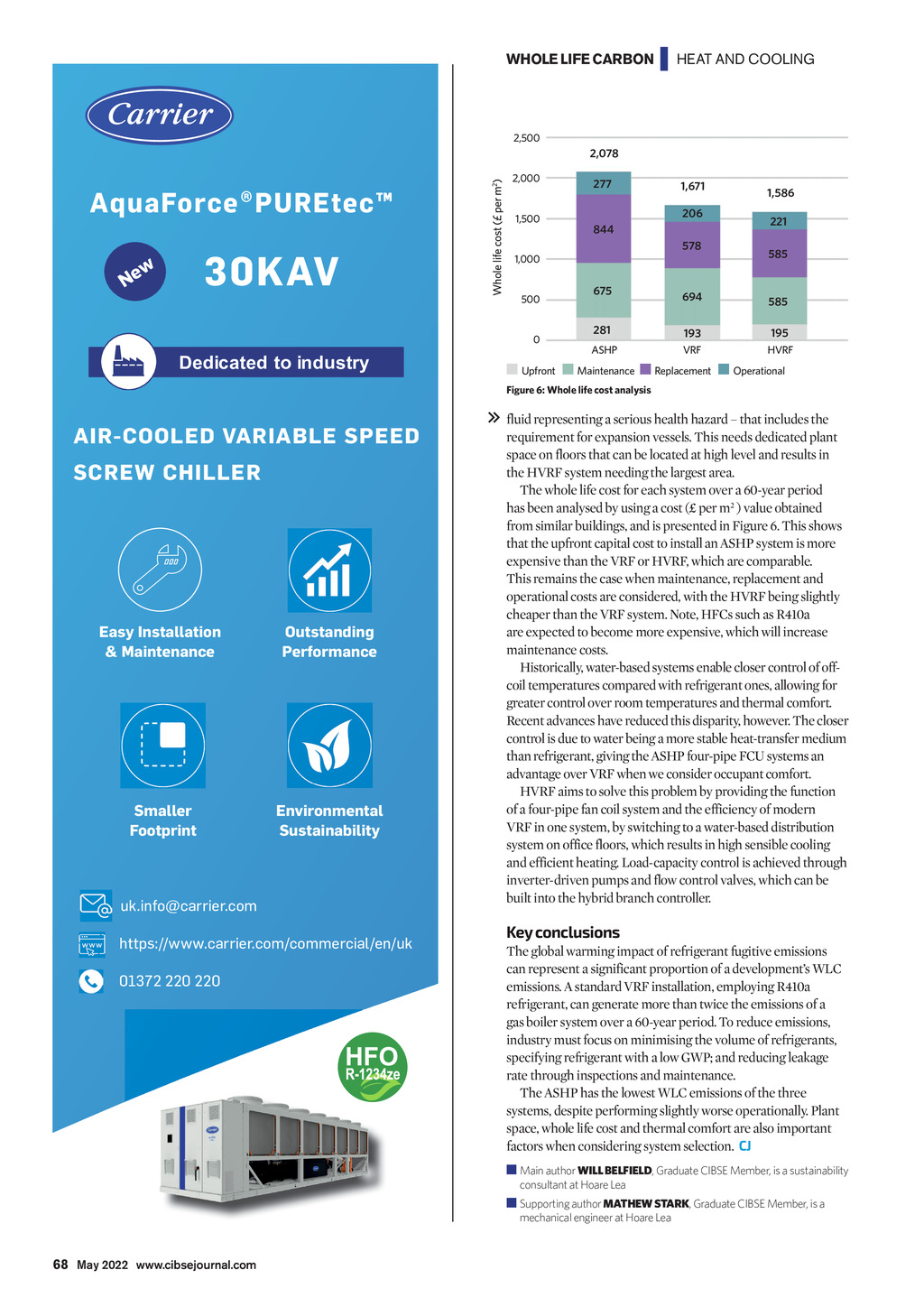

WHOLE LIFE CARBON | HEAT AND COOLING 2,500 AquaForcePUREtec 30KAV ew N Whole life cost ( per m2) 2,078 2,000 1,500 500 1,671 206 844 578 1,000 0 Dedicated to industry 277 675 694 1,586 221 585 585 281 193 195 ASHP VRF HVRF Upfront Maintenance Replacement Operational Figure 6: Whole life cost analysis AIR-COOLED VARIABLE SPEED SCREW CHILLER Easy Installation & Maintenance Outstanding Performance Smaller Footprint Environmental Sustainability uk.info@carrier.com https://www.carrier.com/commercial/en/uk 01372 220 220 fluid representing a serious health hazard that includes the requirement for expansion vessels. This needs dedicated plant space on floors that can be located at high level and results in the HVRF system needing the largest area. The whole life cost for each system over a 60-year period has been analysed by using a cost ( per m2 ) value obtained from similar buildings, and is presented in Figure 6. This shows that the upfront capital cost to install an ASHP system is more expensive than the VRF or HVRF, which are comparable. This remains the case when maintenance, replacement and operational costs are considered, with the HVRF being slightly cheaper than the VRF system. Note, HFCs such as R410a are expected to become more expensive, which will increase maintenance costs. Historically, water-based systems enable closer control of offcoil temperatures compared with refrigerant ones, allowing for greater control over room temperatures and thermal comfort. Recent advances have reduced this disparity, however. The closer control is due to water being a more stable heat-transfer medium than refrigerant, giving the ASHP four-pipe FCU systems an advantage over VRF when we consider occupant comfort. HVRF aims to solve this problem by providing the function of a four-pipe fan coil system and the efficiency of modern VRF in one system, by switching to a water-based distribution system on office floors, which results in high sensible cooling and efficient heating. Load-capacity control is achieved through inverter-driven pumps and flow control valves, which can be built into the hybrid branch controller. Key conclusions The global warming impact of refrigerant fugitive emissions can represent a significant proportion of a developments WLC emissions. A standard VRF installation, employing R410a refrigerant, can generate more than twice the emissions of a gas boiler system over a 60-year period. To reduce emissions, industry must focus on minimising the volume of refrigerants, specifying refrigerant with a low GWP; and reducing leakage rate through inspections and maintenance. The ASHP has the lowest WLC emissions of the three systems, despite performing slightly worse operationally. Plant space, whole life cost and thermal comfort are also important factors when considering system selection. CJ Main author WILL BELFIELD, Graduate CIBSE Member, is a sustainability consultant at Hoare Lea Supporting author MATHEW STARK, Graduate CIBSE Member, is a mechanical engineer at Hoare Lea 68 May 2022 www.cibsejournal.com CIBSE May 22 pp64-66, 68 Whole life carbon cooling and heating.indd 68 22/04/2022 18:13