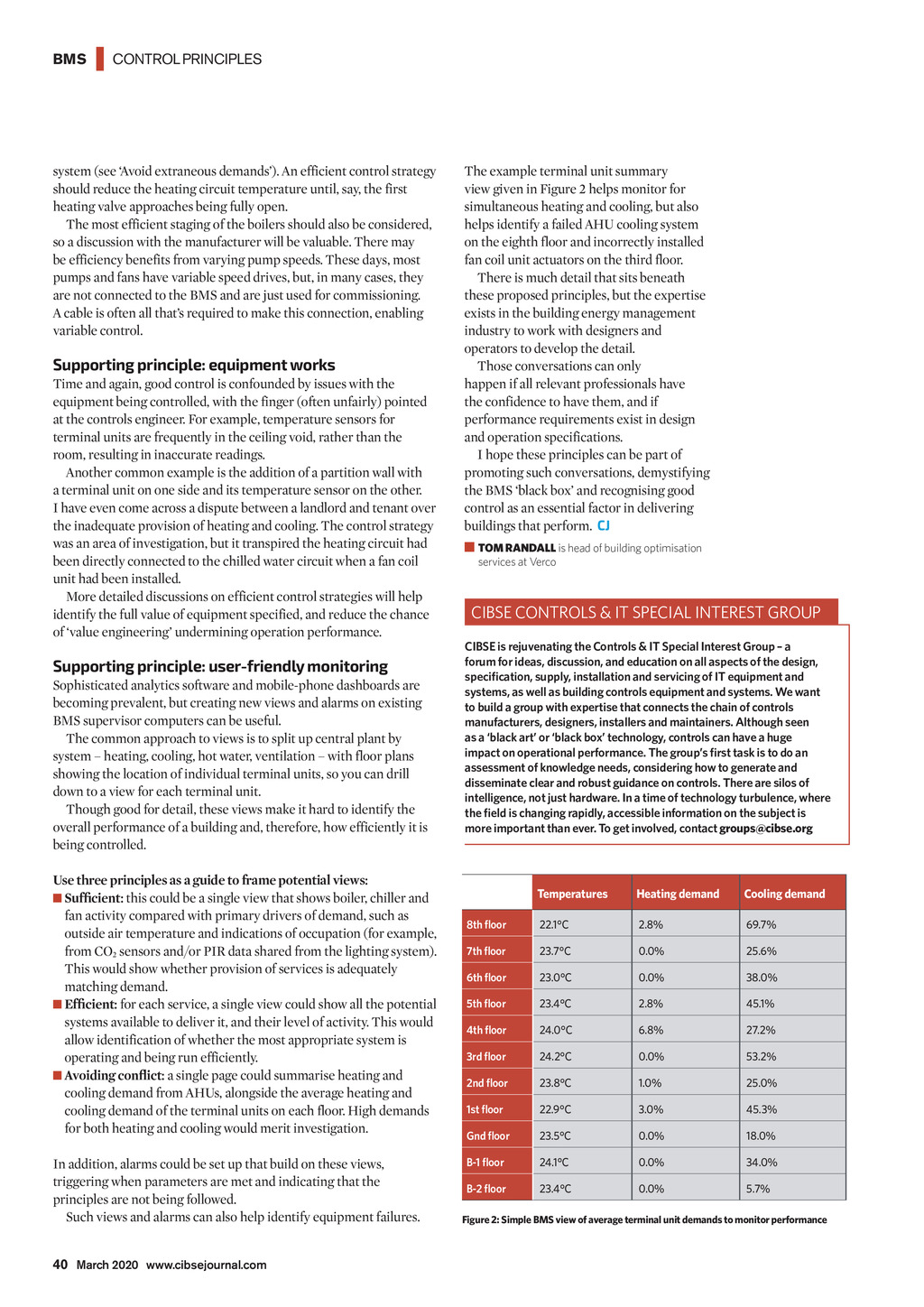

BMS | CONTROL PRINCIPLES system (see Avoid extraneous demands). An efficient control strategy should reduce the heating circuit temperature until, say, the first heating valve approaches being fully open. The most efficient staging of the boilers should also be considered, so a discussion with the manufacturer will be valuable. There may be efficiency benefits from varying pump speeds. These days, most pumps and fans have variable speed drives, but, in many cases, they are not connected to the BMS and are just used for commissioning. A cable is often all thats required to make this connection, enabling variable control. Supporting principle: equipment works Time and again, good control is confounded by issues with the equipment being controlled, with the finger (often unfairly) pointed at the controls engineer. For example, temperature sensors for terminal units are frequently in the ceiling void, rather than the room, resulting in inaccurate readings. Another common example is the addition of a partition wall with a terminal unit on one side and its temperature sensor on the other. I have even come across a dispute between a landlord and tenant over the inadequate provision of heating and cooling. The control strategy was an area of investigation, but it transpired the heating circuit had been directly connected to the chilled water circuit when a fan coil unit had been installed. More detailed discussions on efficient control strategies will help identify the full value of equipment specified, and reduce the chance of value engineering undermining operation performance. Supporting principle: user-friendly monitoring Sophisticated analytics software and mobile-phone dashboards are becoming prevalent, but creating new views and alarms on existing BMS supervisor computers can be useful. The common approach to views is to split up central plant by system heating, cooling, hot water, ventilation with floor plans showing the location of individual terminal units, so you can drill down to a view for each terminal unit. Though good for detail, these views make it hard to identify the overall performance of a building and, therefore, how efficiently it is being controlled. Use three principles as a guide to frame potential views: Sufficient: this could be a single view that shows boiler, chiller and fan activity compared with primary drivers of demand, such as outside air temperature and indications of occupation (for example, from CO2 sensors and/or PIR data shared from the lighting system). This would show whether provision of services is adequately matching demand. Efficient: for each service, a single view could show all the potential systems available to deliver it, and their level of activity. This would allow identification of whether the most appropriate system is operating and being run efficiently. Avoiding conflict: a single page could summarise heating and cooling demand from AHUs, alongside the average heating and cooling demand of the terminal units on each floor. High demands for both heating and cooling would merit investigation. In addition, alarms could be set up that build on these views, triggering when parameters are met and indicating that the principles are not being followed. Such views and alarms can also help identify equipment failures. The example terminal unit summary view given in Figure 2 helps monitor for simultaneous heating and cooling, but also helps identify a failed AHU cooling system on the eighth floor and incorrectly installed fan coil unit actuators on the third floor. There is much detail that sits beneath these proposed principles, but the expertise exists in the building energy management industry to work with designers and operators to develop the detail. Those conversations can only happen if all relevant professionals have the confidence to have them, and if performance requirements exist in design and operation specifications. I hope these principles can be part of promoting such conversations, demystifying the BMS black box and recognising good control as an essential factor in delivering buildings that perform. CJ TOM RANDALL is head of building optimisation services at Verco CIBSE CONTROLS & IT SPECIAL INTEREST GROUP CIBSE is rejuvenating the Controls & IT Special Interest Group a forum for ideas, discussion, and education on all aspects of the design, specification, supply, installation and servicing of IT equipment and systems, as well as building controls equipment and systems. We want to build a group with expertise that connects the chain of controls manufacturers, designers, installers and maintainers. Although seen as a black art or black box technology, controls can have a huge impact on operational performance. The groups first task is to do an assessment of knowledge needs, considering how to generate and disseminate clear and robust guidance on controls. There are silos of intelligence, not just hardware. In a time of technology turbulence, where the field is changing rapidly, accessible information on the subject is more important than ever. To get involved, contact groups@cibse.org Temperatures Heating demand Cooling demand 8th floor 22.1C 2.8% 69.7% 7th floor 23.7C 0.0% 25.6% 6th floor 23.0C 0.0% 38.0% 5th floor 23.4C 2.8% 45.1% 4th floor 24.0C 6.8% 27.2% 3rd floor 24.2C 0.0% 53.2% 2nd floor 23.8C 1.0% 25.0% 1st floor 22.9C 3.0% 45.3% Gnd floor 23.5C 0.0% 18.0% B-1 floor 24.1C 0.0% 34.0% B-2 floor 23.4C 0.0% 5.7% Figure 2: Simple BMS view of average terminal unit demands to monitor performance 40 March 2020 www.cibsejournal.com CIBSE Mar20 pp38-40 Controls.indd 40 21/02/2020 14:54