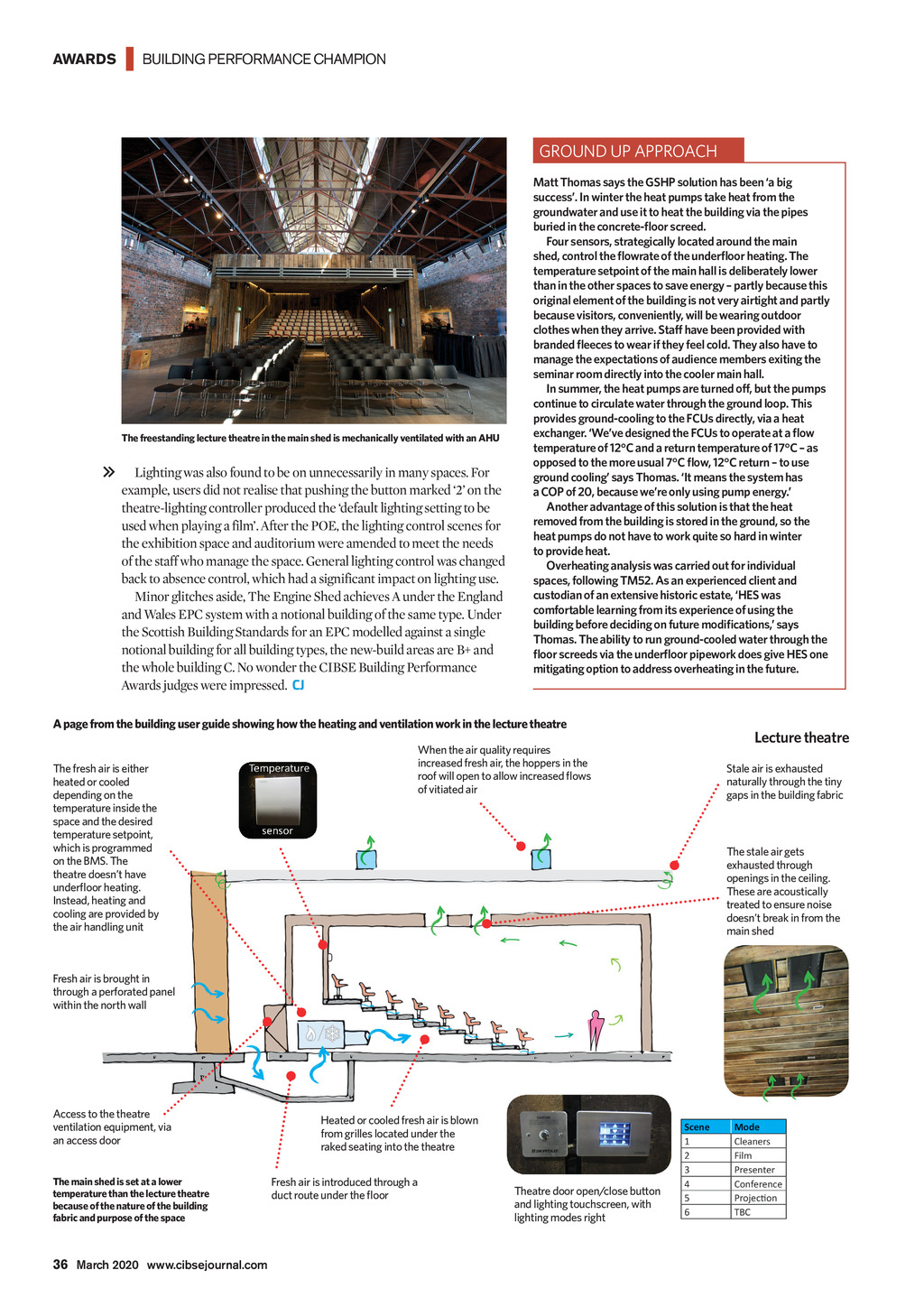

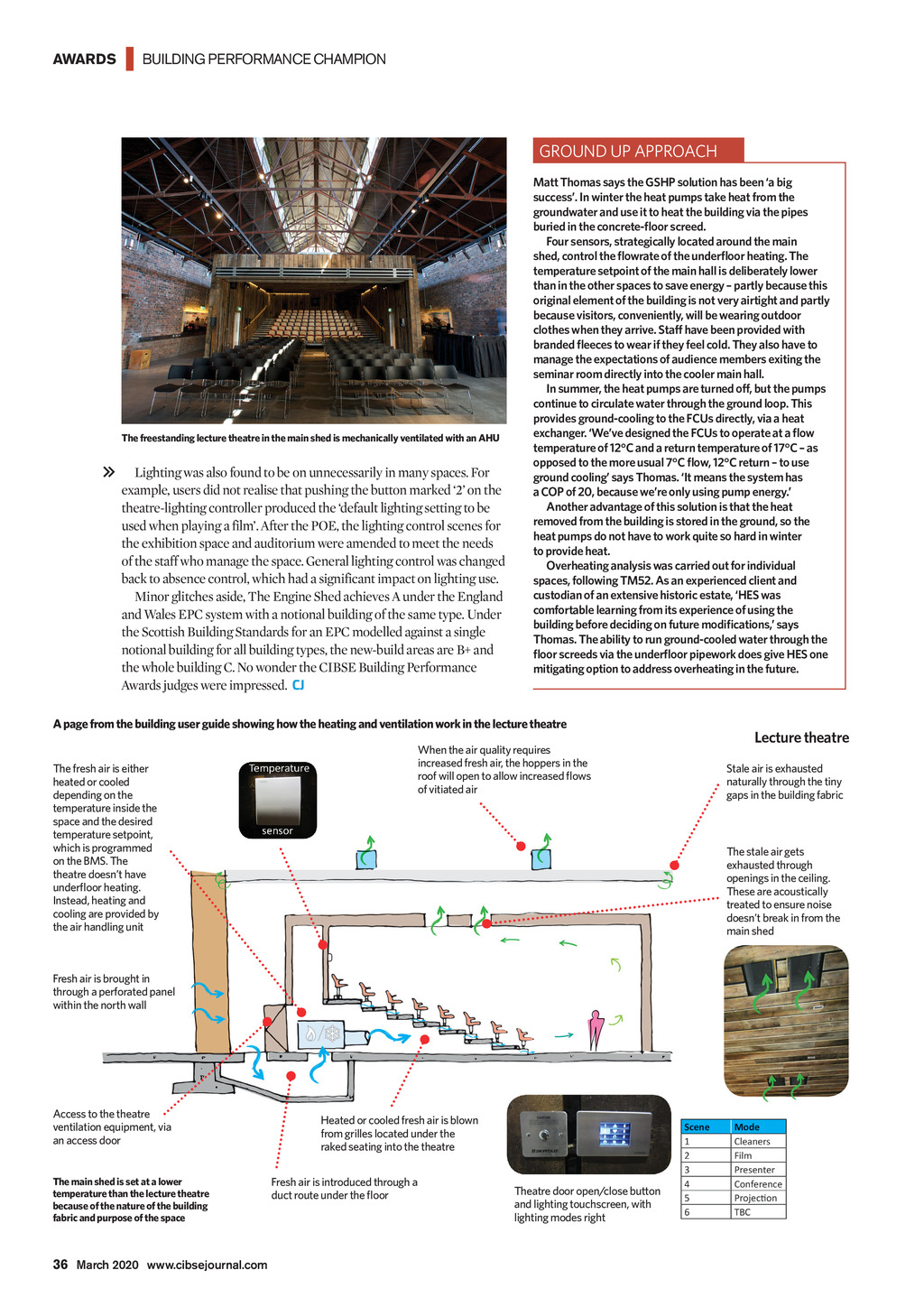

AWARDS | BUILDING PERFORMANCE CHAMPION GROUND UP APPROACH The freestanding lecture theatre in the main shed is mechanically ventilated with an AHU Lighting was also found to be on unnecessarily in many spaces. For example, users did not realise that pushing the button marked 2 on the theatre-lighting controller produced the default lighting setting to be used when playing a film. After the POE, the lighting control scenes for the exhibition space and auditorium were amended to meet the needs of the staff who manage the space. General lighting control was changed back to absence control, which had a significant impact on lighting use. Minor glitches aside, The Engine Shed achieves A under the England and Wales EPC system with a notional building of the same type. Under the Scottish Building Standards for an EPC modelled against a single notional building for all building types, the new-build areas are B+ and the whole building C. No wonder the CIBSE Building Performance Awards judges were impressed. CJ Matt Thomas says the GSHP solution has been a big success. In winter the heat pumps take heat from the groundwater and use it to heat the building via the pipes buried in the concrete-floor screed. Four sensors, strategically located around the main shed, control the flowrate of the underfloor heating. The temperature setpoint of the main hall is deliberately lower than in the other spaces to save energy partly because this original element of the building is not very airtight and partly because visitors, conveniently, will be wearing outdoor clothes when they arrive. Staff have been provided with branded fleeces to wear if they feel cold. They also have to manage the expectations of audience members exiting the seminar room directly into the cooler main hall. In summer, the heat pumps are turned off, but the pumps continue to circulate water through the ground loop. This provides ground-cooling to the FCUs directly, via a heat exchanger. Weve designed the FCUs to operate at a flow temperature of 12C and a return temperature of 17C as opposed to the more usual 7C flow, 12C return to use ground cooling says Thomas. It means the system has a COP of 20, because were only using pump energy. Another advantage of this solution is that the heat removed from the building is stored in the ground, so the heat pumps do not have to work quite so hard in winter to provide heat. Overheating analysis was carried out for individual spaces, following TM52. As an experienced client and custodian of an extensive historic estate, HES was comfortable learning from its experience of using the building before deciding on future modifications, says Thomas. The ability to run ground-cooled water through the floor screeds via the underfloor pipework does give HES one mitigating option to address overheating in the future. A page from the building user guide showing how the heating and ventilation work in the lecture theatre The fresh air is either heated or cooled depending on the temperature inside the space and the desired temperature setpoint, which is programmed on the BMS. The theatre doesnt have underfloor heating. Instead, heating and cooling are provided by the air handling unit When the air quality requires increased fresh air, the hoppers in the roof will open to allow increased flows of vitiated air Lecture theatre Stale air is exhausted naturally through the tiny gaps in the building fabric The stale air gets exhausted through openings in the ceiling. These are acoustically treated to ensure noise doesnt break in from the main shed Fresh air is brought in through a perforated panel within the north wall Access to the theatre ventilation equipment, via an access door The main shed is set at a lower temperature than the lecture theatre because of the nature of the building fabric and purpose of the space Heated or cooled fresh air is blown from grilles located under the raked seating into the theatre Fresh air is introduced through a duct route under the floor Theatre door open/close button and lighting touchscreen, with lighting modes right 36 March 2020 www.cibsejournal.com CIBSE Mar20 pp32-36 Engine shed.indd 36 21/02/2020 14:52