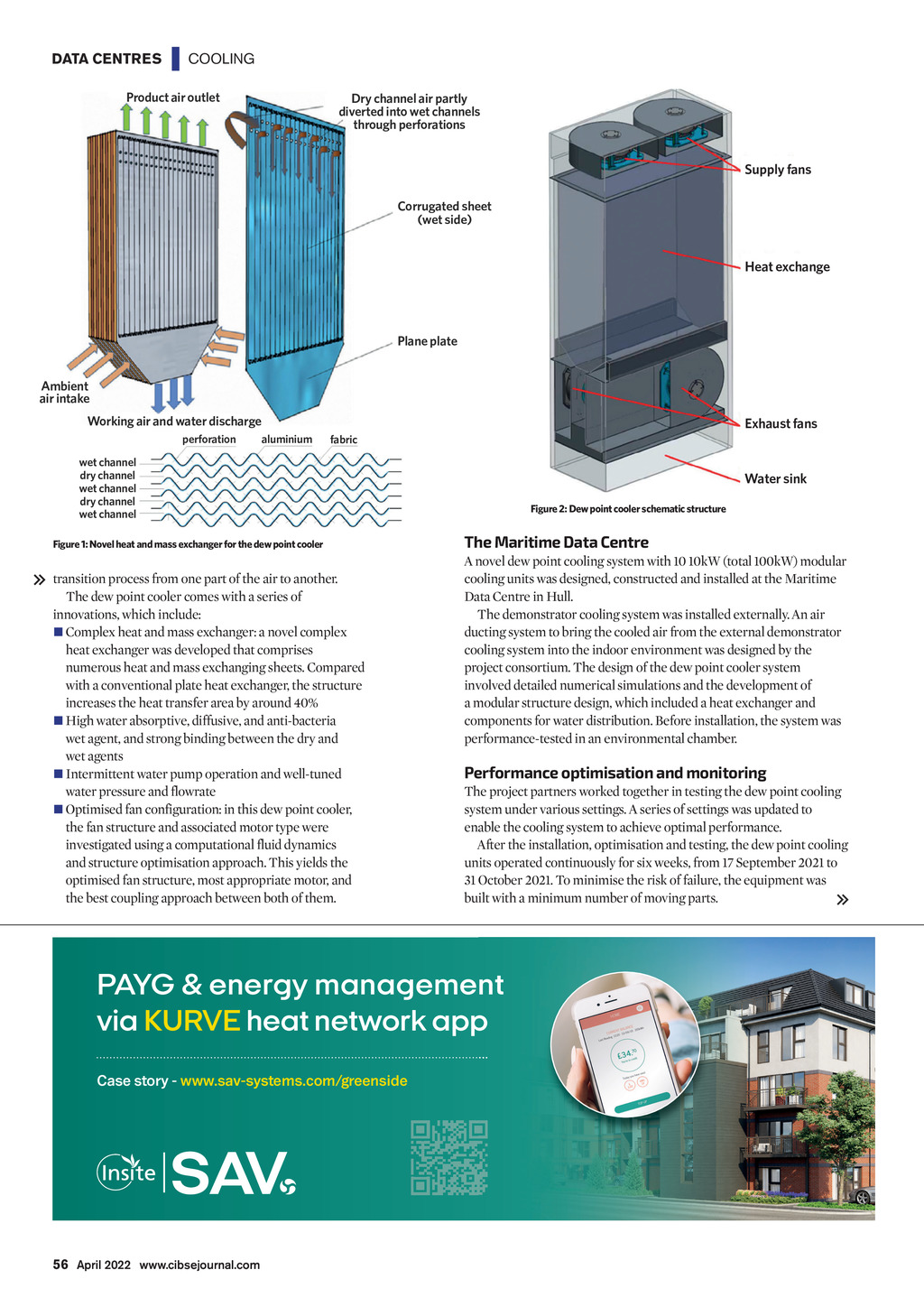

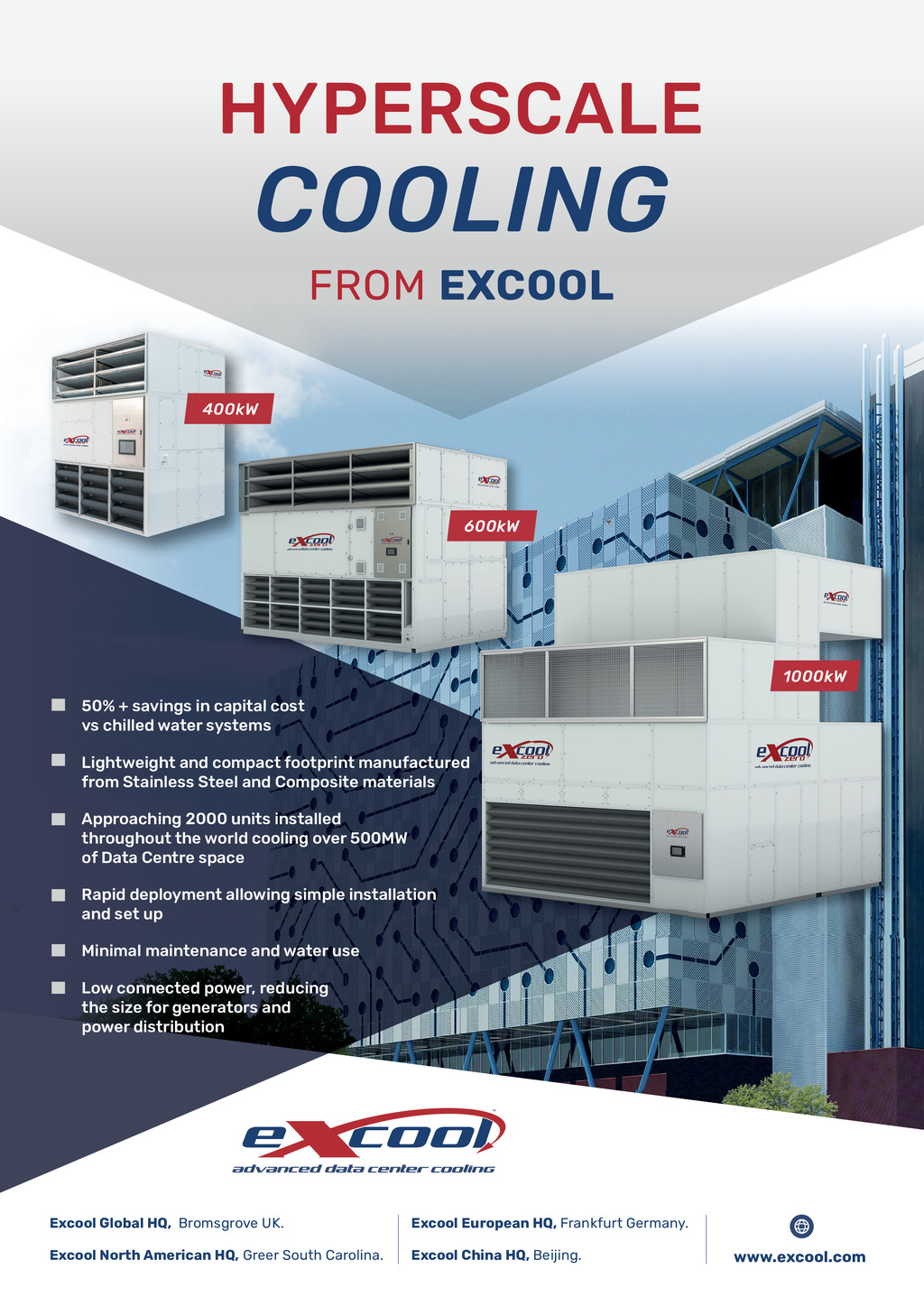

DATA CENTRES | COOLING Product air outlet Dry channel air partly diverted into wet channels through perforations Supply fans Corrugated sheet (wet side) Heat exchange Plane plate Ambient air intake Working air and water discharge perforation aluminium Exhaust fans fabric wet channel dry channel wet channel dry channel wet channel Figure 1: Novel heat and mass exchanger for the dew point cooler transition process from one part of the air to another. The dew point cooler comes with a series of innovations, which include: Complex heat and mass exchanger: a novel complex heat exchanger was developed that comprises numerous heat and mass exchanging sheets. Compared with a conventional plate heat exchanger, the structure increases the heat transfer area by around 40% High water absorptive, diffusive, and anti-bacteria wet agent, and strong binding between the dry and wet agents Intermittent water pump operation and well-tuned water pressure and flowrate Optimised fan configuration: in this dew point cooler, the fan structure and associated motor type were investigated using a computational fluid dynamics and structure optimisation approach. This yields the optimised fan structure, most appropriate motor, and the best coupling approach between both of them. Water sink Figure 2: Dew point cooler schematic structure The Maritime Data Centre A novel dew point cooling system with 10 10kW (total 100kW) modular cooling units was designed, constructed and installed at the Maritime Data Centre in Hull. The demonstrator cooling system was installed externally. An air ducting system to bring the cooled air from the external demonstrator cooling system into the indoor environment was designed by the project consortium. The design of the dew point cooler system involved detailed numerical simulations and the development of a modular structure design, which included a heat exchanger and components for water distribution. Before installation, the system was performance-tested in an environmental chamber. Performance optimisation and monitoring The project partners worked together in testing the dew point cooling system under various settings. A series of settings was updated to enable the cooling system to achieve optimal performance. After the installation, optimisation and testing, the dew point cooling units operated continuously for six weeks, from 17 September 2021 to 31 October 2021. To minimise the risk of failure, the equipment was built with a minimum number of moving parts. PAYG & energy management via KURVE heat network app Case story - www.sav-systems.com/greenside 56 April 2022 www.cibsejournal.com CIBSE Apr 22 pp55-56, 58 Dew point cooler.indd 56 25/03/2022 15:21