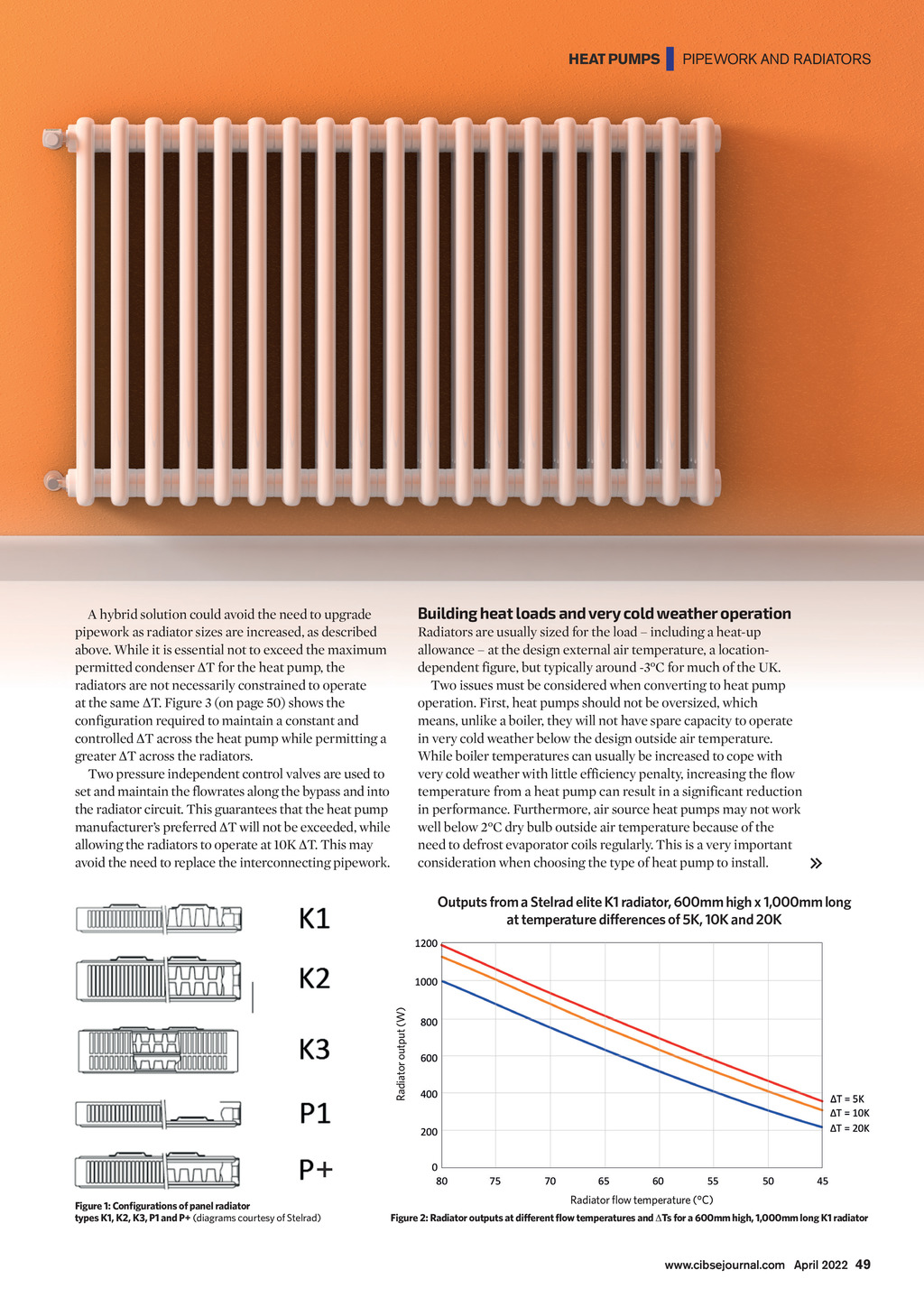

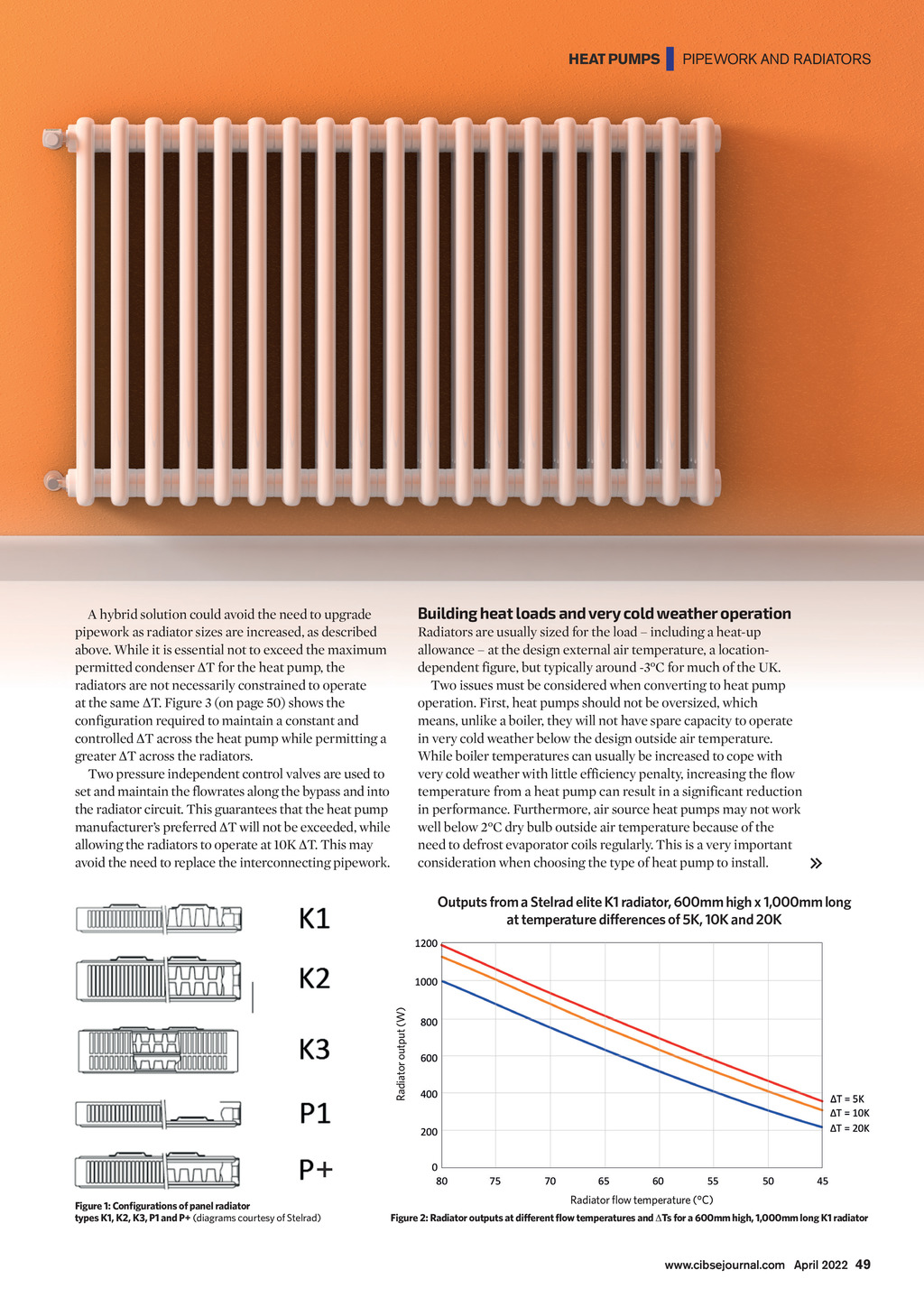

HEAT PUMPS | PIPEWORK AND RADIATORS RADICAL DEPARTURE? RETROFITTING FOR HEAT PUMPS With the pressure on homeowners to replace domestic gas boilers with heat pumps, it is essential that engineers ensure that existing radiators and pipework are suitable for the lower-temperature heat source. David Palmer looks at the key considerations when upgrading a heating system W ithin a few years, every heating designer and contractor in the UK will be installing heat pumps and upgrading heating systems. This will require the reskilling of engineers and contractors, not only in the design and installation of heat pump systems, but also in the upgrading of heat emitters and pipework to operate at low temperatures. This article addresses radiator and pipework upgrades for domestic heating installations, excluding hot water provision. Operation at much lower flow temperatures will result in significantly lower radiator outputs, and heat pumps which require a typical 5K maximum temperature drop will require higher flow rates which may necessitate the replacement of heating pipework. The output from a radiator is a function of the flow temperature (Tf ), return temperature (Tr) and room ambient temperature (Ta) as defined in BS 442 as follows: Output (W) = Output @75-65-20 X Tf +Tr -Ta 2 50 n-coefcient The output at 75C flow, 65C return and 20C ambient (75/65/20) and the n-coefficient exponent are radiator dependent, and are supplied by the manufacturer in radiator output tables in accordance with BS 442. Radiators are described by the number of panels and fins, as shown in Figure 1. The industry standard panel radiator, from which all radiator outputs are calculated, is of type K1, 600mm high and 1,000mm long. At 75/65/20, the output is 1W per mm of radiator length to give a total of 1kW. The output at other temperatures can be calculated using the equation above, and is shown in Figure 2: From the above, it is clear that operation at temperatures well below the typical 80C/60C or 82C/71C results in dramatically reduced radiator outputs, and that it is not possible to simply replace a boiler with a heat pump without taking measures to upgrade the building insulation, increase the size of the radiators, or both. From a baseline of 5K T across a radiator, increasing the radiator T by 1K decreases the radiator output by between 1.0% and 1.3% for each 1K increase in T above 5K. The output of this radiator at 5K T at 45/40/20 is 36% of that at 80/60/20, while, at 10K T, it is 31% of that at 80/60/20. Radiator pipework The majority of heat pumps require a very low condenser T, typically 5K. If upgraded radiators are operated at a temperature difference of 5K, rather than the current 11K or 20K, the existing pipework may be too small and may have to be replaced. Whether or not pipework needs to be upgraded along with radiators depends on the pipework material and internal pipe diameter. Take the example of a K1 radiator 600mm high x 1,000mm long, operating at 80/60/20 with an output of 1kW. If the radiator is upgraded to a K3 700mm high x 1,000mm long, at 45/40/20, it would produce almost the same output, 963W. If connected to 10mm 5-layer PEX barrier pipe (internal diameter 6.7mm) the pressure loss would be 3,822Pa.m-1 at 1.32m.s-1 velocity. If connected to 8mm copper minibore pipe (internal diameter 6.8mm), the pressure loss would be 3,646 Pa.m-1 at 1.28 m.s-1. The significant increases in pressure drop, and potential increase in noise, may necessitate upgrading the pipework. By comparison, for the 700mm/1,000mm K3 radiator at 10K T ie, 45/35/20 the output would be only 821W, giving 846Pa.m-1 and 0.56m.s-1 for 10mm PEX or 799Pa.m-1 and 0.55m.s-1 for 8mm copper. Operating at 7K T ie, 45/38/20 the output would be 906W, giving 1,881Pa.m-1 and 0.89m.s-1 for 10mm PEX, and 1,786Pa.m-1 and 0.86m.s-1 for 8mm copper. In both of these situations, it is very likely that the existing pipework could be reused. 48 April 2022 www.cibsejournal.com CIBSE Apr 22 pp48-50 Upgrading homes for heat pumps.indd 48 25/03/2022 14:35