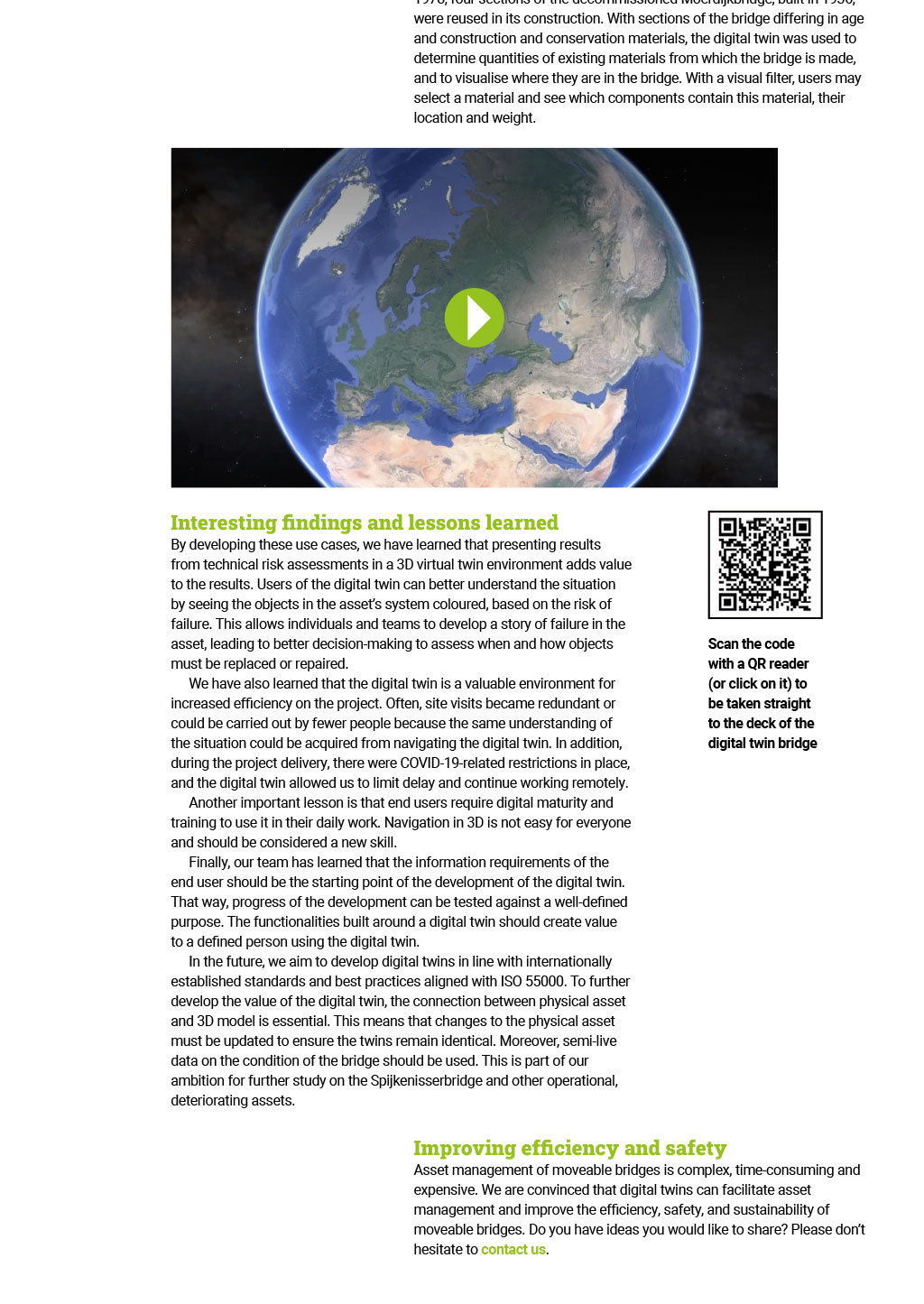

Knowledge base Digital twins have become a realistic solution for asset owners. Here, Rudolph Jauregui, Hanno Spoelstra and Ilona Kemeling, from Arcadis Netherlands, show how this digital option helped improve the efficiency, safety and circularity of a 1970s lift bridge Essentially, digital twins comprise a digital representation of a physical asset system, computing devices, and (semi-) live data-collection applications. The concept allows asset managers to fuse sensory data with an assets digital model, and to use that for monitoring, controlling, and optimising the assets performance. Here, we describe our experience using a digital twin to support some asset management activities for the Spijkenisserbrug: a vertical-lift bridge with two independent lifting decks. We developed a model based on a 3D point cloud and design drawings, and added information and functionality to enable the use of the model as a digital twin for asset management. The challenge The Spijkenisserbrug spans the Oude Maas river, an important waterway for seagoing vessels accessing Rotterdam harbour and the Dutch river system. It was built in 1978. In the past, the bridge was shown to be outdated and was proving to be less and less reliable. As the projected use increases from the current 6,800 bridge movements per year to 7,500 per year in the future, renovation is required. Rijkswaterstaat (RWS), the Directorate-General for Public Works and Water Management of the Netherlands, and the asset owner, aims to prevent failures and to reduce the number of malfunctions. This is done by conducting regular (preventative) maintenance and doing technical risk assessments. Additionally, as safety requirements change, RWS must make sure that existing assets can be upgraded to comply with new machine-safety regulations. These and many other asset management-related activities take place in the context of a world that is striving for sustainability. Experts and specialists from engineering firms normally use traditional ways to give the necessary advice on the above-mentioned activities. Moreover, findings are recorded in pre-formatted documents that are sent to the technical department of RWS for further decision-making. Digital twins for asset management A digital twin is a realistic digital representation of something physical. The most important part of a digital twin, which sets it apart from an As-Built Building Information Model (BIM), is its direct relationship with the real world, its physical twin. Connections are essential in transferring data between the twins, and services include decision-making and monitoring or control of the physical asset. The Spijkenisserbrug is a road bridge over the Oude Maas, a tidal river, between the Dutch towns of Hoogvliet and Spijkenisse. The provincial road N492 runs over this bridge By developing these use cases, we have learned that presenting results from technical risk assessments in a 3D virtual twin environment adds value to the results With sections of the bridge differing in age and construction and conservation materials, the digital twin was used to determine quantities of existing materials from which the bridge is made, and to visualise where they are in the bridge From 2D on paper to a 3D model in the cloud Arcadis developed a model based on a 3D point cloud and design drawings, and added information and functionality to enable the use of the model as a digital twin for asset management. We built three functionalities in the digital twin to support the job of specialists and experts in their activities to give advice on maintenance of the bridge. These were: visualisation of the technical risk assessment; machine-safety compliance; and circularity. 1. Visualisation of the technical risk assessment The outcomes of the technical risk assessments of physical assets are traditionally presented in hard-copy reports. These assessments, in the field of asset management, consist of a valuation of the risk of failure when a system fails to fulfil its designed function. The reports typically contain the factors generating the risk, an explanation of the risk, its consequences, and a score that classifies the risk. For Spijkenisserbrug, the digital twin was used to visualise the findings from the technical risk assessment. This allowed experts and the client to visualise the different risks present across the bridge quickly and in an insightful manner. Users could access the parts of interest very easily. Results from the risk assessment were assigned to the elements and components of the digital twin so that users and the client could visualise and understand them in context. Low, medium, and high risks were represented, highlighting the components in green, yellow or red, respectively. Findings supporting the results of the risk assessment could also be accessed from the digital twin. 2. Compliance with machine-safety regulations To achieve compliance with machine-safety regulations, the steps include information assessment, elimination of risks, and control of risks that might occur when using machines. For doing assessments on existing assets, the information must first be collected on site, followed by analysis and interpretation in the office, then verified on site, and finally presented to the client in a report. The digital twin supported all the steps involved in doing this assessment. During the phase of the data collection, experts were able to prepare their activities to gather the data with the support of the digital twin. This decreased the time needed to gather the data on site. In addition, other time-consuming activities, such as taking and registering measurements or dimensions, were minimised. During the phase of analysis and interpretation of the data, the digital twin helped experts in fulfilling the assessment and collaboration aspects. The use of the digital twin allowed experts to go back digitally to the bridge to look for missing data or to evaluate certain aspects again that might still not have been clarified. Finally, the digital twin was also used to present the results to the client. It was used during technical meetings to show the progress of the work and to present the findings in the final report with the assessment on machine safety. 3. Circularity in replacement materials Circularity in the construction sector is about reusing or recycling materials from existing assets. Interestingly, when the Spijkenisserbrug was built in 1978, four sections of the decommissioned Moerdijk bridge, built in 1936, were reused in its construction. With sections of the bridge differing in age and construction and conservation materials, the digital twin was used to determine quantities of existing materials from which the bridge is made, and to visualise where they are in the bridge. With a visual filter, users may select a material and see which components contain this material, their location and weight. Interesting findings and lessons learned By developing these use cases, we have learned that presenting results from technical risk assessments in a 3D virtual twin environment adds value to the results. Users of the digital twin can better understand the situation by seeing the objects in the assets system coloured, based on the risk of failure. This allows individuals and teams to develop a story of failure in the asset, leading to better decision-making to assess when and how objects must be replaced or repaired. We have also learned that the digital twin is a valuable environment for increased efficiency on the project. Often, site visits became redundant or could be carried out by fewer people because the same understanding of the situation could be acquired from navigating the digital twin. In addition, during the project delivery, there were COVID-19-related restrictions in place, and the digital twin allowed us to limit delay and continue working remotely. Another important lesson is that end users require digital maturity and training to use it in their daily work. Navigation in 3D is not easy for everyone and should be considered a new skill. Finally, our team has learned that the information requirements of the end user should be the starting point of the development of the digital twin. That way, progress of the development can be tested against a well-defined purpose. The functionalities built around a digital twin should create value to a defined person using the digital twin. In the future, we aim to develop digital twins in line with internationally established standards and best practices aligned with ISO 55000. To further develop the value of the digital twin, the connection between physical asset and 3D model is essential. This means that changes to the physical asset must be updated to ensure the twins remain identical. Moreover, semi-live data on the condition of the bridge should be used. This is part of our ambition for further study on the Spijkenisserbrug and other operational, deteriorating assets. Scan the code with a QR reader (or click on it) to be taken straight to the deck of the digital twin bridge Improving efficiency and safety Asset management of moveable bridges is complex, time-consuming and expensive. We are convinced that digital twins can facilitate asset management and improve the efficiency, safety, and sustainability of moveable bridges. Do you have ideas you would like to share? Please dont hesitate to contact us.