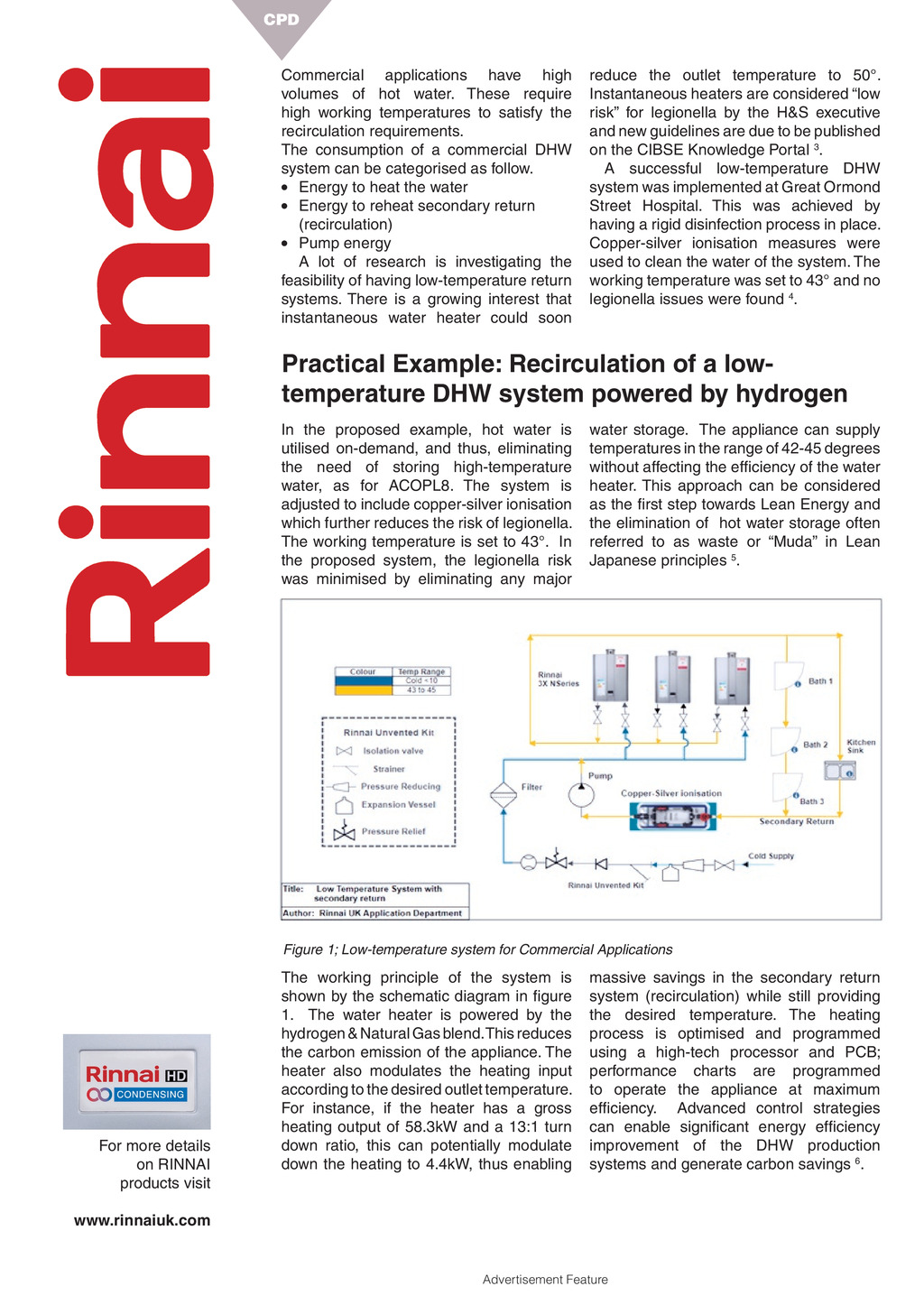

CPD Commercial applications have high volumes of hot water. These require high working temperatures to satisfy the recirculation requirements. The consumption of a commercial DHW system can be categorised as follow. Energy to heat the water Energy to reheat secondary return (recirculation) Pump energy A lot of research is investigating the feasibility of having low-temperature return systems. There is a growing interest that instantaneous water heater could soon O O O reduce the outlet temperature to 50. Instantaneous heaters are considered low risk for legionella by the H&S executive and new guidelines are due to be published on the CIBSE Knowledge Portal 3. A successful low-temperature DHW system was implemented at Great Ormond Street Hospital. This was achieved by having a rigid disinfection process in place. Copper-silver ionisation measures were used to clean the water of the system. The working temperature was set to 43 and no legionella issues were found 4. Practical Example: Recirculation of a lowtemperature DHW system powered by hydrogen In the proposed example, hot water is utilised on-demand, and thus, eliminating the need of storing high-temperature water, as for ACOPL8. The system is adjusted to include copper-silver ionisation which further reduces the risk of legionella. The working temperature is set to 43. In the proposed system, the legionella risk was minimised by eliminating any major water storage. The appliance can supply temperatures in the range of 42-45 degrees without affecting the efciency of the water heater. This approach can be considered as the rst step towards Lean Energy and the elimination of hot water storage often referred to as waste or Muda in Lean Japanese principles 5. Figure 1; Low-temperature system for Commercial Applications For more details on RINNAI products visit The working principle of the system is shown by the schematic diagram in gure 1. The water heater is powered by the hydrogen & Natural Gas blend.This reduces the carbon emission of the appliance. The heater also modulates the heating input according to the desired outlet temperature. For instance, if the heater has a gross heating output of 58.3kW and a 13:1 turn down ratio, this can potentially modulate down the heating to 4.4kW, thus enabling massive savings in the secondary return system (recirculation) while still providing the desired temperature. The heating process is optimised and programmed using a high-tech processor and PCB; performance charts are programmed to operate the appliance at maximum efciency. Advanced control strategies can enable signicant energy efciency improvement of the DHW production systems and generate carbon savings 6. www.rinnaiuk.com 52 September 2021 www.cibsejournal.com Advertisement Feature p52-53.CIBSEMagSept21.indd 52 23/08/2021 11:42