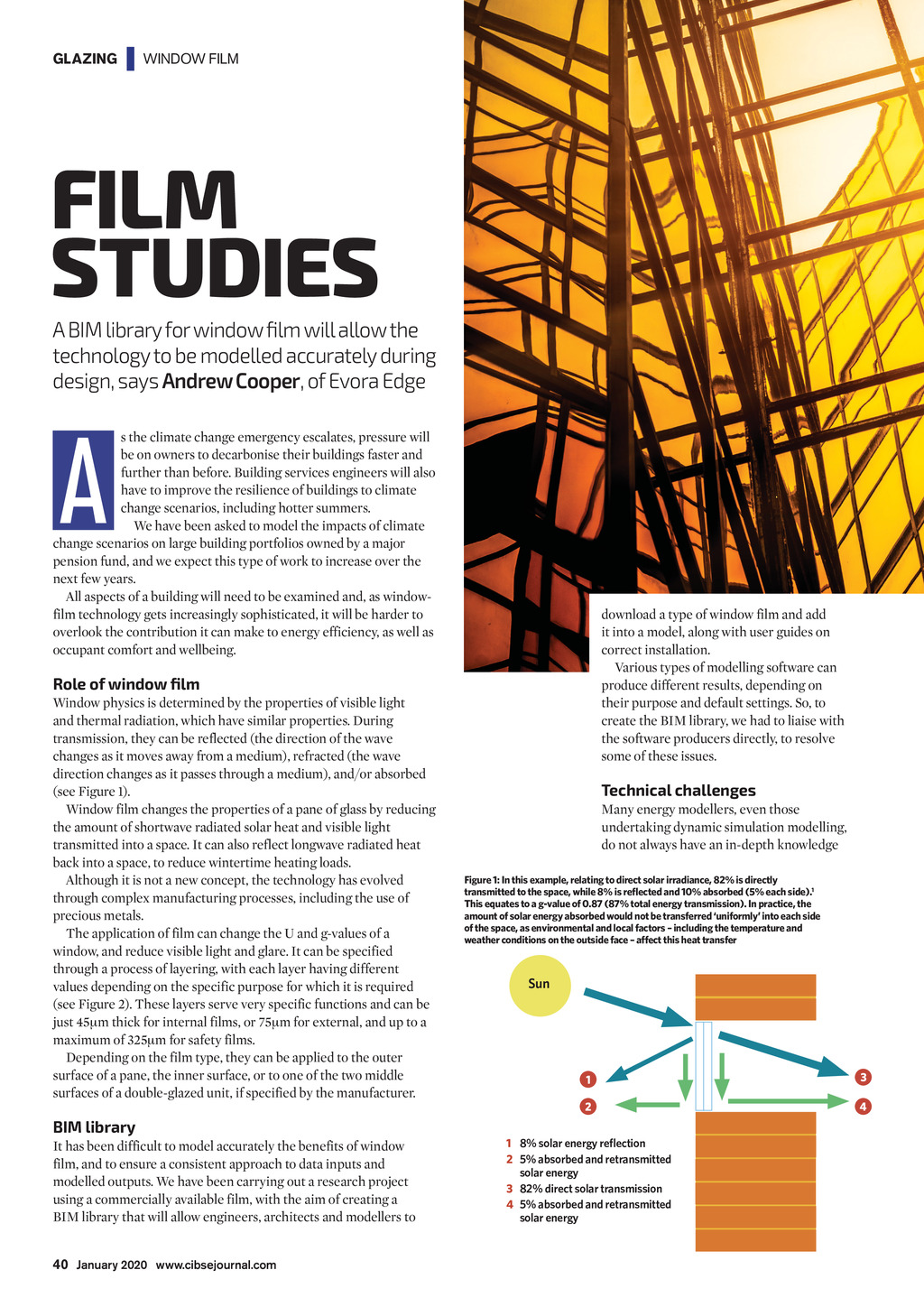

GLAZING | WINDOW FILM FILM STUDIES A BIM library for window film will allow the technology to be modelled accurately during design, says Andrew Cooper, of Evora Edge A s the climate change emergency escalates, pressure will be on owners to decarbonise their buildings faster and further than before. Building services engineers will also have to improve the resilience of buildings to climate change scenarios, including hotter summers. We have been asked to model the impacts of climate change scenarios on large building portfolios owned by a major pension fund, and we expect this type of work to increase over the next few years. All aspects of a building will need to be examined and, as windowfilm technology gets increasingly sophisticated, it will be harder to overlook the contribution it can make to energy efficiency, as well as occupant comfort and wellbeing. download a type of window film and add it into a model, along with user guides on correct installation. Various types of modelling software can produce different results, depending on their purpose and default settings. So, to create the BIM library, we had to liaise with the software producers directly, to resolve some of these issues. Role of window film Window physics is determined by the properties of visible light and thermal radiation, which have similar properties. During transmission, they can be reflected (the direction of the wave changes as it moves away from a medium), refracted (the wave direction changes as it passes through a medium), and/or absorbed (see Figure 1). Window film changes the properties of a pane of glass by reducing the amount of shortwave radiated solar heat and visible light transmitted into a space. It can also reflect longwave radiated heat back into a space, to reduce wintertime heating loads. Although it is not a new concept, the technology has evolved through complex manufacturing processes, including the use of precious metals. The application of film can change the U and g-values of a window, and reduce visible light and glare. It can be specified through a process of layering, with each layer having different values depending on the specific purpose for which it is required (see Figure 2). These layers serve very specific functions and can be just 45m thick for internal films, or 75m for external, and up to a maximum of 325m for safety films. Depending on the film type, they can be applied to the outer surface of a pane, the inner surface, or to one of the two middle surfaces of a double-glazed unit, if specified by the manufacturer. BIM library It has been difficult to model accurately the benefits of window film, and to ensure a consistent approach to data inputs and modelled outputs. We have been carrying out a research project using a commercially available film, with the aim of creating a BIM library that will allow engineers, architects and modellers to Technical challenges Many energy modellers, even those undertaking dynamic simulation modelling, do not always have an in-depth knowledge Figure 1: In this example, relating to direct solar irradiance, 82% is directly transmitted to the space, while 8% is reflected and 10% absorbed (5% each side).1 This equates to a g-value of 0.87 (87% total energy transmission). In practice, the amount of solar energy absorbed would not be transferred uniformly into each side of the space, as environmental and local factors including the temperature and weather conditions on the outside face affect this heat transfer Sun 1 8% solar energy reflection 2 5% absorbed and retransmitted solar energy 382% direct solar transmission 45% absorbed and retransmitted solar energy 40 January 2020 www.cibsejournal.com CIBSE Jan20 pp40-42 Window film.indd 40 20/12/2019 15:28