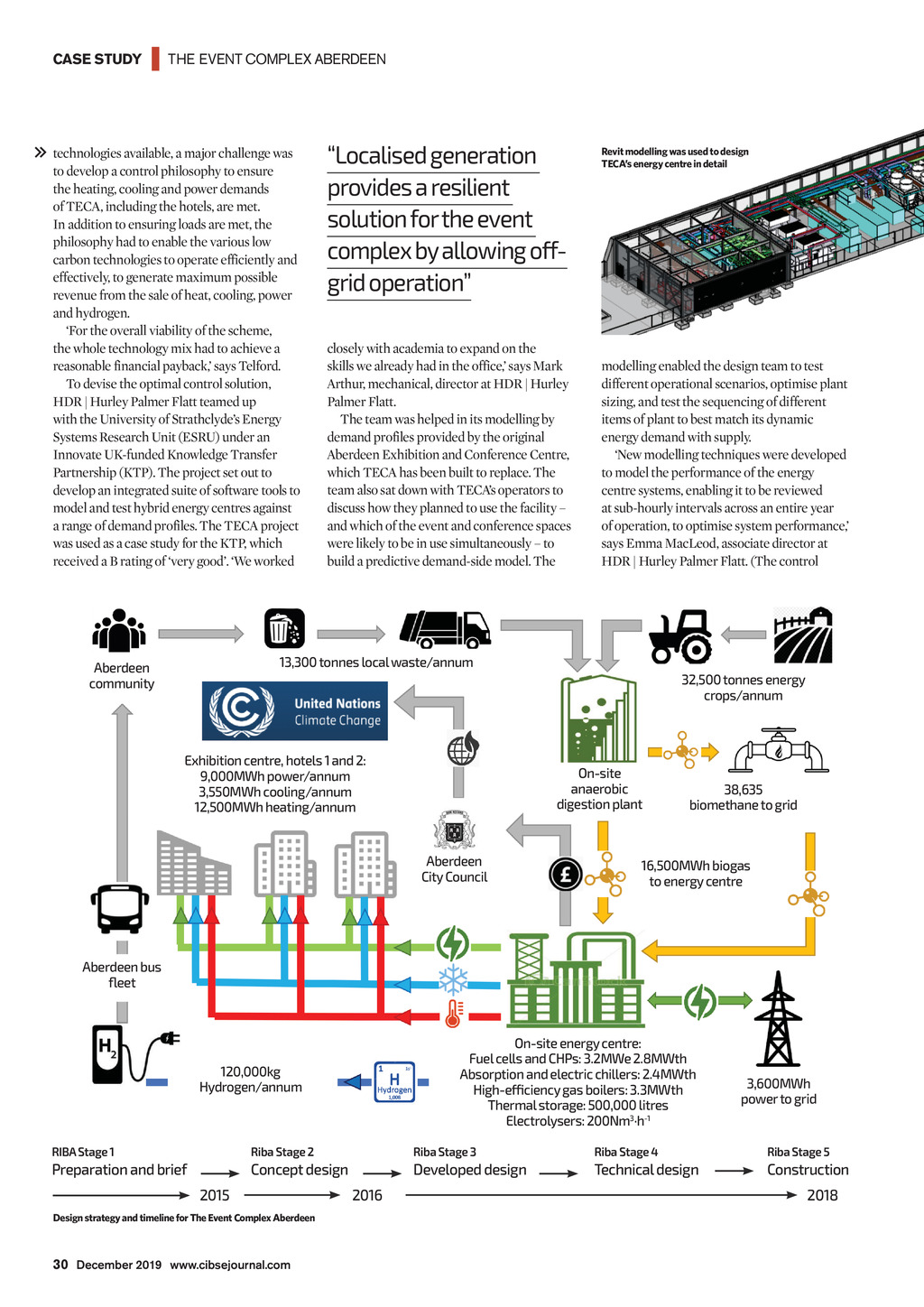

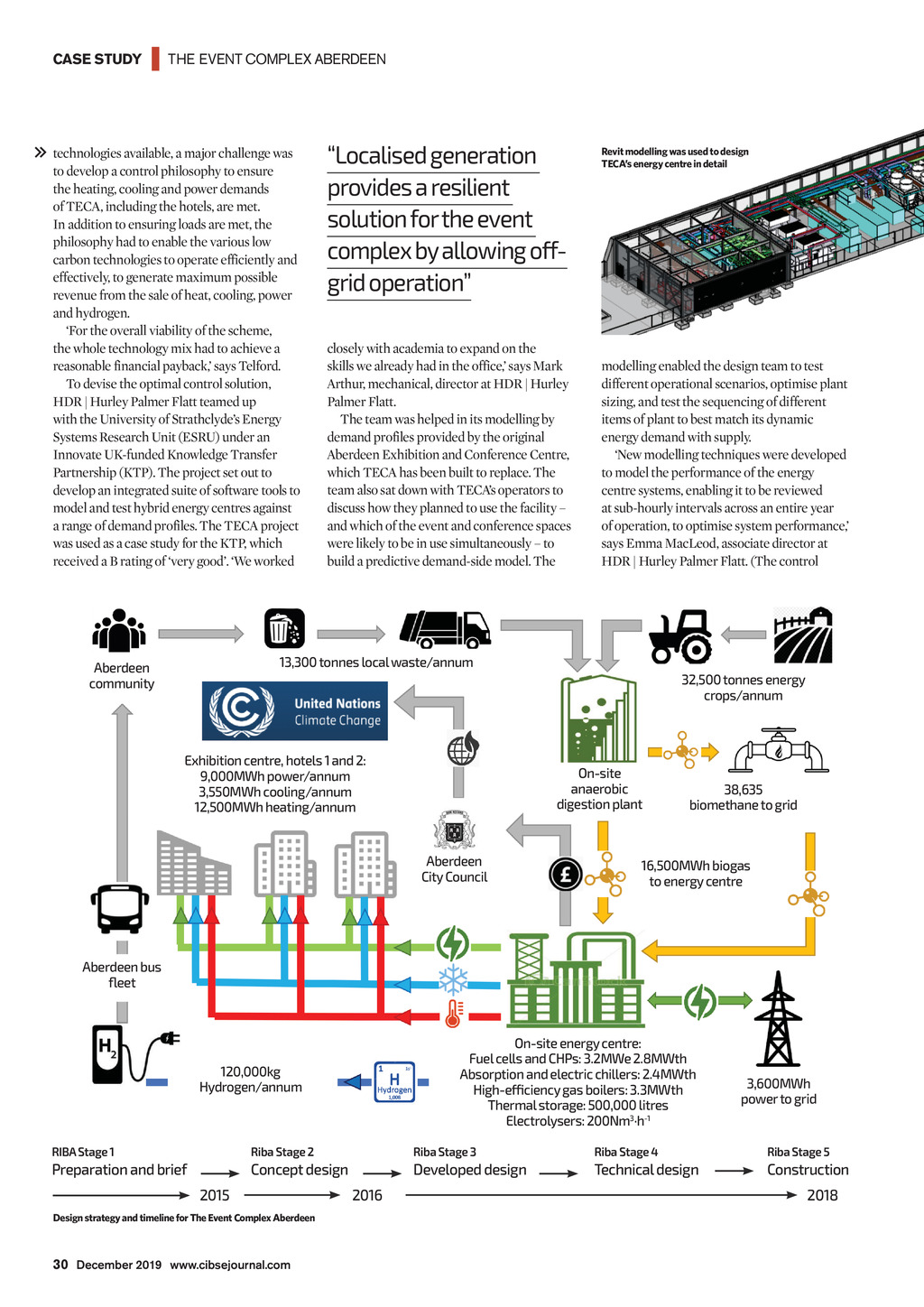

CASE STUDY | THE EVENT COMPLEX ABERDEEN technologies available, a major challenge was to develop a control philosophy to ensure the heating, cooling and power demands of TECA, including the hotels, are met. In addition to ensuring loads are met, the philosophy had to enable the various low carbon technologies to operate efficiently and effectively, to generate maximum possible revenue from the sale of heat, cooling, power and hydrogen. For the overall viability of the scheme, the whole technology mix had to achieve a reasonable financial payback, says Telford. To devise the optimal control solution, HDR | Hurley Palmer Flatt teamed up with the University of Strathclydes Energy Systems Research Unit (ESRU) under an Innovate UK-funded Knowledge Transfer Partnership (KTP). The project set out to develop an integrated suite of software tools to model and test hybrid energy centres against a range of demand profiles. The TECA project was used as a case study for the KTP, which received a B rating of very good. We worked Localised generation provides a resilient solution for the event complex by allowing offgrid operation closely with academia to expand on the skills we already had in the office, says Mark Arthur, mechanical, director at HDR | Hurley Palmer Flatt. The team was helped in its modelling by demand profiles provided by the original Aberdeen Exhibition and Conference Centre, which TECA has been built to replace. The team also sat down with TECAs operators to discuss how they planned to use the facility and which of the event and conference spaces were likely to be in use simultaneously to build a predictive demand-side model. The Revit modelling was used to design TECAs energy centre in detail modelling enabled the design team to test different operational scenarios, optimise plant sizing, and test the sequencing of different items of plant to best match its dynamic energy demand with supply. New modelling techniques were developed to model the performance of the energy centre systems, enabling it to be reviewed at sub-hourly intervals across an entire year of operation, to optimise system performance, says Emma MacLeod, associate director at HDR | Hurley Palmer Flatt. (The control 13,300 tonnes local waste/annum Aberdeen community 32,500 tonnes energy crops/annum Exhibition centre, hotels 1 and 2: 9,000MWh power/annum 3,550MWh cooling/annum 12,500MWh heating/annum On-site anaerobic digestion plant Aberdeen City Council 38,635 biomethane to grid 16,500MWh biogas to energy centre Aberdeen bus fleet On-site energy centre: Fuel cells and CHPs: 3.2MWe 2.8MWth Absorption and electric chillers: 2.4MWth High-efficiency gas boilers: 3.3MWth Thermal storage: 500,000 litres Electrolysers: 200Nm3.h-1 120,000kg Hydrogen/annum 3,600MWh power to grid RIBA Stage 1 Riba Stage 2 Riba Stage 3 Riba Stage 4 Riba Stage 5 Preparation and brief Concept design Developed design Technical design Construction 2015 2016 2018 Design strategy and timeline for The Event Complex Aberdeen 30 December 2019 www.cibsejournal.com CIBSE Dec19 pp28-31 Aberdeen centre.indd 30 22/11/2019 15:23