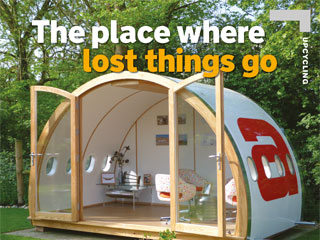

The place where lost things go Call it what you will: a man-cave, she-shed or garden room An afterlife for retired aircraft – in your home By Captain Robin Evans, Senior Log Contributor here are three parts to material greening: reduce, reuse and recycle, all increasingly practised in aviation and beyond. Newest generation airliners employ increased production efficiency and recyclability: 3D printing and carbon-fibre separation, for example. The constant drive for commercial lightweighting ensures that assets are as light as they can be. In autumn 2017, BALPA featured the trade in aircraft end-of-life treatment at Air Salvage International (ASI) in Kemble. After a lifespan of around 15-20 years, market forces drive airliners towards a ‘jet cemetery’ such as ASI. This is where the embedded value of components exceeds the asset as a whole, and usable parts are harvested. Recent events have only accelerated the depreciation of types such as the A380 and 747. Reuse focuses on extracting maximum value components such as engines, gear and avionics. Fuselages are often sectioned for training rigs, or torn apart and reincarnated in low-grade applications. Hiding in plain sight between the expensive and expansive are smaller components: fan blades, cowlings and window sections. Their iconic design and abundant nature brings them to the attention of upcyclers. A concept particularly familiar to designers, the upcycling movement accelerated in the 1990s, credited to British ‘salvo’ guru Thornton Kay. The art of finding and reworking materials gained traction and, for aircraft, this has become the domain of initiative-based enterprises such as DappR Aviation. Leap of faith Only a pilot’s eye would notice the unusual object sitting outside an otherwise ordinary industrial unit near Bury St Edmunds. The breaker’s torch was not the end of the line for this A320 fuselage section. Delivered to TACA El Salvador, it flew for Izmir Airlines and AtlasJet before arriving here via ASI. “It was a huge leap of faith to buy our first plane,” says David Palmer, DappR Aviation founder. “We kept the original fuselage, windows and insulation and built a bespoke, full aspect, double-glazed frontage.” Call it what you will: a man-cave, she-shed or garden room, DappR calls it the AeroPod. It has traversed the country on the exhibition circuit, most recently Grand Designs Live. Inside the hangar, another is under way: after an electrical fix and finishing touches, it’ll roll out of the door and into a customer’s garden. Up close, I can’t resist patting the huge, arching gluelam (glued laminate) beam that frames the glazed frontage. A balloon pilot and aviation enthusiast, David originally ran an IT recycling business. From here, it was a logical step into avionics disposal and another towards the rest of the aircraft. On discovering how much was scrapped, he decided it was a waste of well-engineered, valuable materials. “We didn’t invent upcycling, but we were in the right place at the right time,” he says. “We bring design and art to recycled components.” A conversation with daughter Emily, a design graduate, provided the spark. Between them, DappR sprouted wings in 2014 and has been airborne ever since – now a six-person, full-time enterprise. Of initial industry scepticism, David says: “It’s easy to create a product, not easy to sustain a business.” Last year was their biggest, blending private commissions with sales and trade fairs. “We reuse and recycle as much as we can,” David says, estimating they divert up to 32 tonnes from landfill. “We’re using it to produce coffee tables, bars, chairs, whatever you fancy.” Selecting the parts The pilot’s eye also spies turbine burner cans and 747 landing gear doors in the workshop. Others are less obvious: David reveals a pair of gleaming metal arms as titanium flap actuator mounts. He explains that DappR selects ‘clean’ parts only, in keeping with the common-sense approach of working with machinery in a workshop environment. Established supplier relationships (including Airbus Helicopters) mean a large stock of parts. “Some we instantly know what to do with, some wait to be realised – either by us or client request,” says Emily. David discusses his attempts to work with various aircraft parts. “Additional permissions are required for some – Tornado or Merlin parts, for instance – with Spitfire parts existing, but very hard to source, otherwise kept for airworthiness. I’d rather see it flying, but if it can’t...” Emily explains they attract a mix of aviation-in-the-blood professionals and outsiders interested in the look. “We meet all sorts of very interesting people,” explaining a commission by a couple who met through flying jobs, their piece incorporating parts from their respective aircraft. Another supplied them with the wheels of a military tank. Emily reveals her strategy for balancing creative experimenting, advancing commissions and manufacturing stock. “Saturday is fun day,” she says, explaining that as long as it fits their ethos of reworking parts, they experiment their way around practical problems, combining design with craftsmanship. Enthusiasm is high and the fun aspect shows in an unusual bespoke gaming The pilot’s eye also spies turbine burner cans in the workshop chair: imagine Alien creator H. R. Giger designing furniture in a delirious fit. Six-feet tall on an arching, wheeled chassis, it blends chair, console and screen with a covering of chains and turbine blades. Everyday items such as seating and tables are popular, often incorporating slabs of treated wood or coloured resin. The metal/wood combination is a particular specialism: bar stools sitting atop rudder jackscrews. Elsewhere, an upended Rolls- Royce Avon casing has a retro gaming machine rising out of a wooden top. Leading edges often recur, concealing kitchen bench uprights or wrapping around TV cabinets. The amount of reused material varies according to what works for the product. David points out a pair of helicopter doors bearing decals and scars of use in the field. “These are pieces in themselves already.” Some supplementing may be required with materials never intended for recombination. David explains their rule: “All parts on display must be original.” Alongside sits a trio of seats, “95% original, some added wood just protects your flooring,” he observes. A galley trolley reveals subtle input: wine bottle racks, with a wooden tray concealed in the top for your lemon slicing. For more complex projects, they work with local trades: two ejector seats sit nearby, leather cushions fitted by a local upholsterer. Emily reveals that when fitting them out, they discovered a slight warp as evidence of their firing in anger. Meeting the brief Besides exploring, there was another reason for visiting Aladdin’s Cave. With the builders in, I would soon have an office space and set David and Emily a challenge. I sketched out a banker’s lamp, the angled hood made from a piece of leading edge, buffed to a retro sheen: could they make one? Except for some dimensions of the alcove it would fill, the brief was open. Emily soon fired back a picture of the leading edge she’d sourced and we were under way. The shade is a section of BAe 146 horizontal stabiliser leading edge, the upright a helicopter gearbox shaft. Connecting the two are welded sections of oil piping concealing the wiring; Emily explains she used household plug chain to feed this through. It was PAT-certified with a switch and plug, the effect completed by a base of burnished wood. Emily says this was the trickiest style of lamp yet attempted: the finished item was the third version. “If we’re not happy with it, the client doesn’t get to see it,” she says. It’s ideal: solid and subtle. While its edges are smooth, as befitting a character piece, it bears signs of honest wear. Pilots and engineers instantly identify the shade, others consider it an abstract piece of industrial origin. In cost, it was a few months of BALPA subs, more than average, but I’ve been through enough lamps, all fallen by the wayside. The aviation build quality speaks for itself. Furthermore, it was a unique piece with a backstory, that I helped design. Diminishing market Returning to aircraft salvage, the BAe 146 parts market is diminishing. Five years ago, about 1,400 specific parts were highly marketable. Now, there’s around a third of that. Continued type withdrawal, with fewer operators needing to maintain smaller fleets, saturates the market. So, if you have an affinity for the 146, or just want part of a retiring type in your home (747 fans take note), now is the time. Emily and David reinforce the idea that, instead of discarding an almost-functional item, with a little ingenuity you can salvage something from it. And, if you can’t, you now know those who can. Their skills helped bring you the words you’ve just read: how’s that for the leading edge of illumination? For more information, contact DappR Aviation @DappR747 Workshop open Friday to Sunday every month (book appointments online) Bury St Edmunds www.dappraviation.com 01359 271 876 UPCYCLING