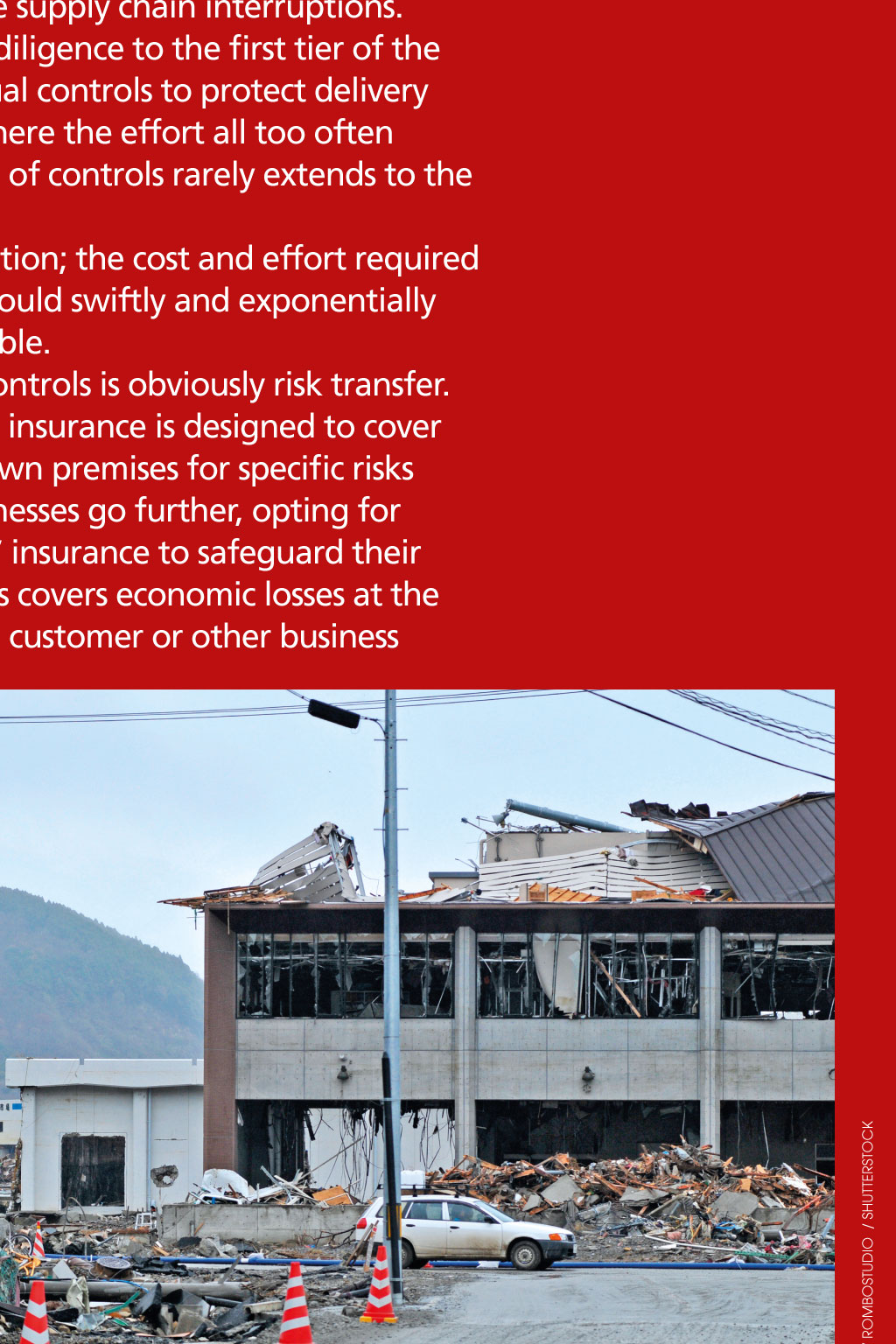

AGInG The suppLy ChaIns 3dreAms/shutterstocK WITH THE InTERCOnnECTEDnESS Of GLOBAL MARkETS InCREASInG, MARK TURNER CIRM COnSIDERS HOW InSURERS ARE RESPOnDInG TO THE CHALLEnGES Of ExTEnDED SUPPLy CHAIn RISk Pull v push supply chains: E arthquakes in Japan happen on a daily basis, and the small ones are usually shrugged off. The 9 magnitude earthquake that hit the fukushima Prefecture on 11 March 2011 was not a small one. It and the resultant tsunami caused indiscriminate death and destruction but the effects were also disproportionately damaging to the global supply chain. Fukushima is one of the worlds major hubs for technology manufacture, including lithium ion batteries for computers, and portable devices and AFLAS rubber used to produce o-rings. Some 60 per cent of the worlds critical automotive components are created there, with more than 20 per cent of the worlds 300mm silicon wafers manufactured in the Shin-Etsu Handotais Shirakawa plant alone. So it wasnt long before countless companies across the world started to feel the impact of the disaster. Until then, many had no idea they were only in business because of the products manufactured in that region. For them, Fukushima was a wake-up call. The modern supply chain has been transformed over the last 30 years. Many manufacturers who once gloried in a diverse product portfolio saw the efficiencies and profit to be made by concentrating on a single specialised product and switched accordingly. The effective chain of suppliers is now many-tiered, with each manufacturer reliant on several others in order to pass their product to their customers, who in turn add value up the chain until the final product is delivered to the end user. While many companies have business continuity strategies, too many are still not designed for such a long chain of dependencies. Many dont consider intermediate supply chain interruptions. The majority still depend on due diligence to the first tier of the supply chain, relying on contractual controls to protect delivery of supplies. And the first tier is where the effort all too often stops. The contractual flow-down of controls rarely extends to the second, third or further suppliers. This isnt just an issue of perception; the cost and effort required for effective multi-level controls could swiftly and exponentially mount into something unachievable. An alternative to contractual controls is obviously risk transfer. Traditional business interruption insurance is designed to cover economic losses at the insureds own premises for specific risks such as fire and flood. Some businesses go further, opting for contingent business interruption insurance to safeguard their supply of critical components. This covers economic losses at the premises of a named supplier, the customer or other business partner for a particular named risk. However, research shows that only 60 per cent of continuity disruptions are caused by tier one suppliers, with a further 30 per cent by tier two, 10 per cent by tier three, and so on. The Fukushima disaster, along with other incidents such as the Icelandic volcanic ash cloud, has prompted many firms to look for alternative cover. What many companies seek is supply chain insurance, and all risk policies have started to appear on the market in recent years. They are designed to cover the economic losses and increased cost of operations caused by any event or circumstance that results from disruption to the insureds operation. If this kind of insurance was able to deliver on its all risks promise, you would safely assume it would be flying off the shelves. The number of risks within the supply chain appears to be on the increase, and todays buyers naturally want cover for all eventualities natural disasters as well as business ones like supplier product recall, bankruptcy and other unforeseeable circumstances. Yet the uptake has been slow. Analysis by Airmic reveals that the main reason for not purchasing is that potential buyers view the cover either as inadequate or unavailable for their specific identified risk. This was followed by the necessary budgets for the cover not being available, the prohibitive cost of the insurance and significantly the view that the underwriting process would be too onerous. While individual policies require different consideration, the approach for all traditional insurance is to identify the risks and indemnify against them. Supply chain insurance extends the depth of the risk assessment to second tier, third tier and beyond. For many buyers this approach fails when the risks are essentially unknown, and the sources cannot be calculated Pull v push supply chains: Pull v push supply chains: In a traditional push supply chain, stock is speculatively manufactured and stored, in the expectation that it will eventually be sold to customers. With the introduction of 3D printing and the Internet of Things (IoT), however, customers can now demand a product that is created only when required. In this way, a pull supply chain emerges. This reduces work in progress, stock in transit and obsolescence of existing stock. de Visu / rombostudio / shutterstocK continuity strategies The impact of the Fukushima disaster did not take long to be felt by countless companies, many of which did not even know that they were reliant on the products manufactured in the region