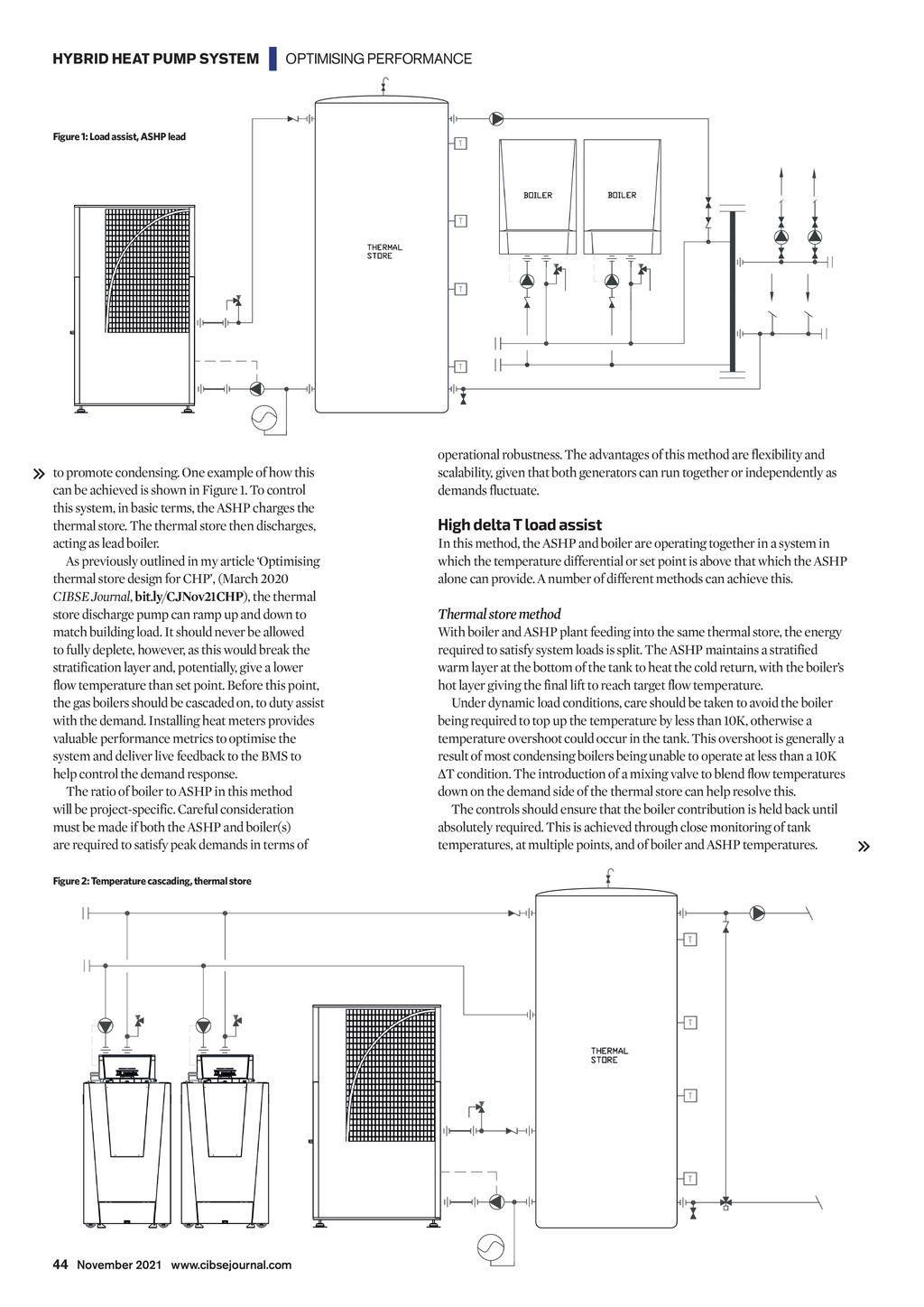

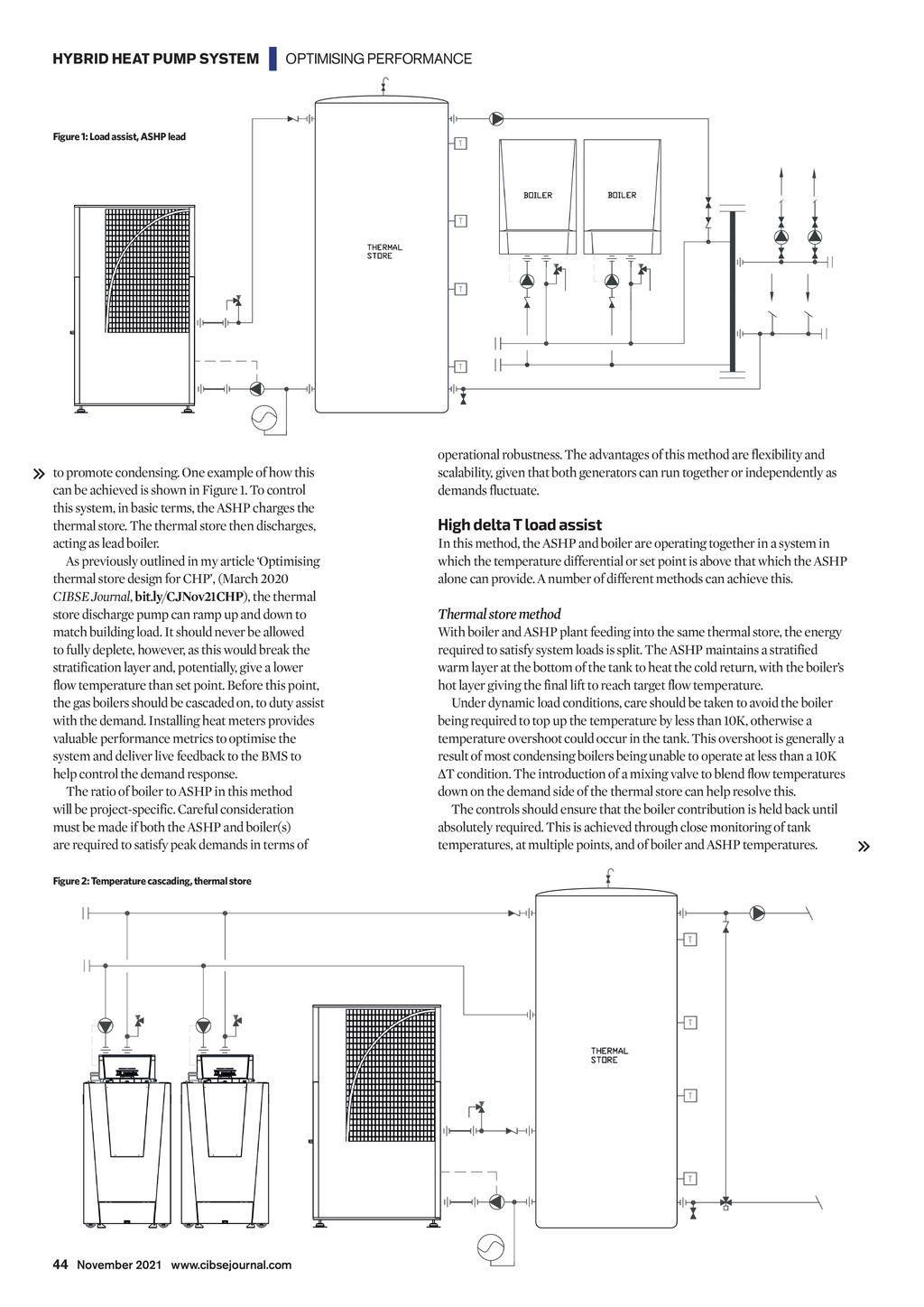

HYBRID HEAT PUMP SYSTEM | OPTIMISING PERFORMANCE Figure 1: Load assist, ASHP lead to promote condensing. One example of how this can be achieved is shown in Figure 1. To control this system, in basic terms, the ASHP charges the thermal store. The thermal store then discharges, acting as lead boiler. As previously outlined in my article Optimising thermal store design for CHP, (March 2020 CIBSE Journal, bit.ly/CJNov21CHP), the thermal store discharge pump can ramp up and down to match building load. It should never be allowed to fully deplete, however, as this would break the stratification layer and, potentially, give a lower flow temperature than set point. Before this point, the gas boilers should be cascaded on, to duty assist with the demand. Installing heat meters provides valuable performance metrics to optimise the system and deliver live feedback to the BMS to help control the demand response. The ratio of boiler to ASHP in this method will be project-specific. Careful consideration must be made if both the ASHP and boiler(s) are required to satisfy peak demands in terms of operational robustness. The advantages of this method are flexibility and scalability, given that both generators can run together or independently as demands fluctuate. High delta T load assist In this method, the ASHP and boiler are operating together in a system in which the temperature differential or set point is above that which the ASHP alone can provide. A number of different methods can achieve this. Thermal store method With boiler and ASHP plant feeding into the same thermal store, the energy required to satisfy system loads is split. The ASHP maintains a stratified warm layer at the bottom of the tank to heat the cold return, with the boilers hot layer giving the final lift to reach target flow temperature. Under dynamic load conditions, care should be taken to avoid the boiler being required to top up the temperature by less than 10K, otherwise a temperature overshoot could occur in the tank. This overshoot is generally a result of most condensing boilers being unable to operate at less than a 10K T condition. The introduction of a mixing valve to blend flow temperatures down on the demand side of the thermal store can help resolve this. The controls should ensure that the boiler contribution is held back until absolutely required. This is achieved through close monitoring of tank temperatures, at multiple points, and of boiler and ASHP temperatures. Figure 2: Temperature cascading, thermal store 44 November 2021 www.cibsejournal.com CIBSE Nov21 pp43-44, 46 Hybrid heat pumps.indd 44 22/10/2021 18:22