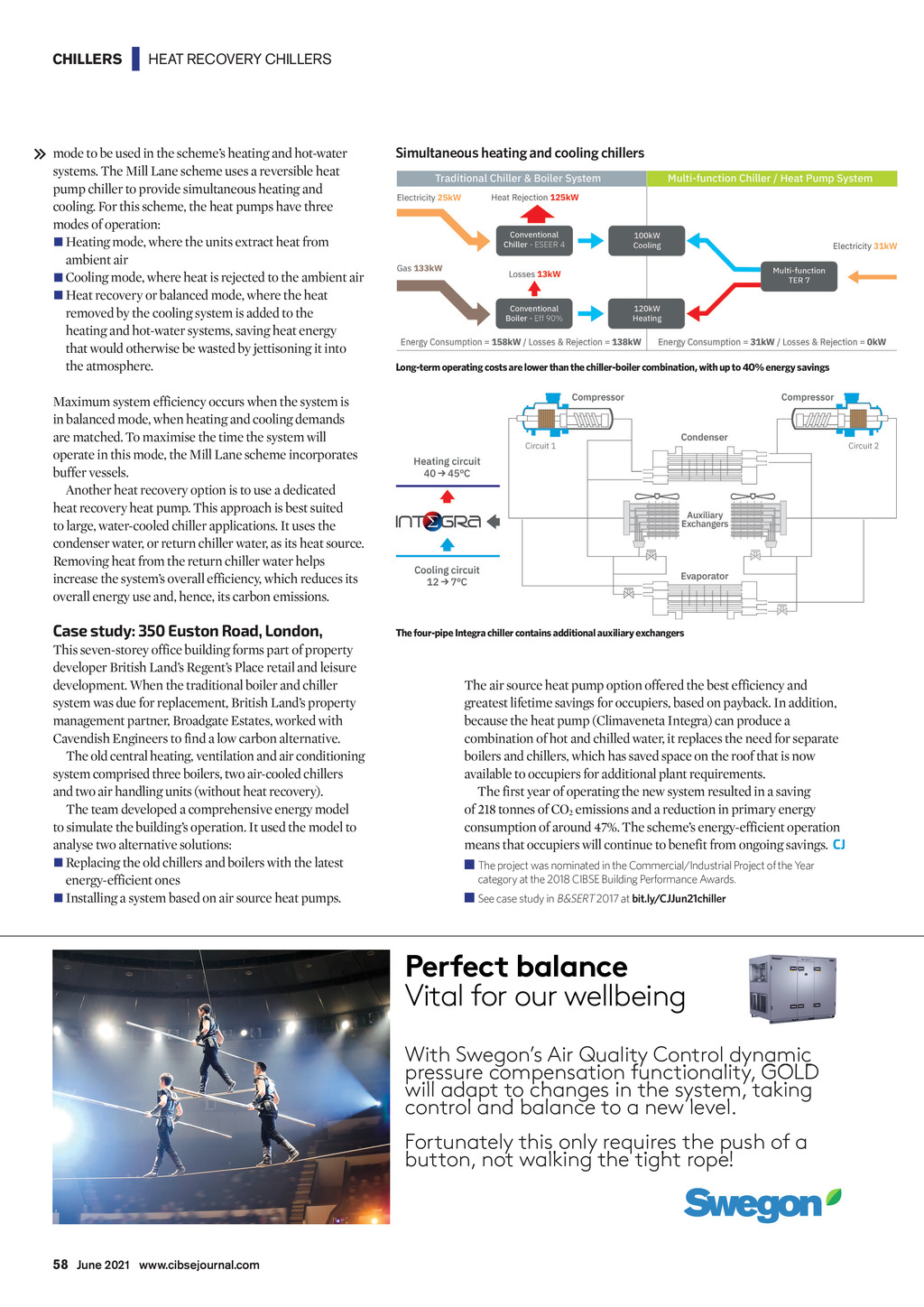

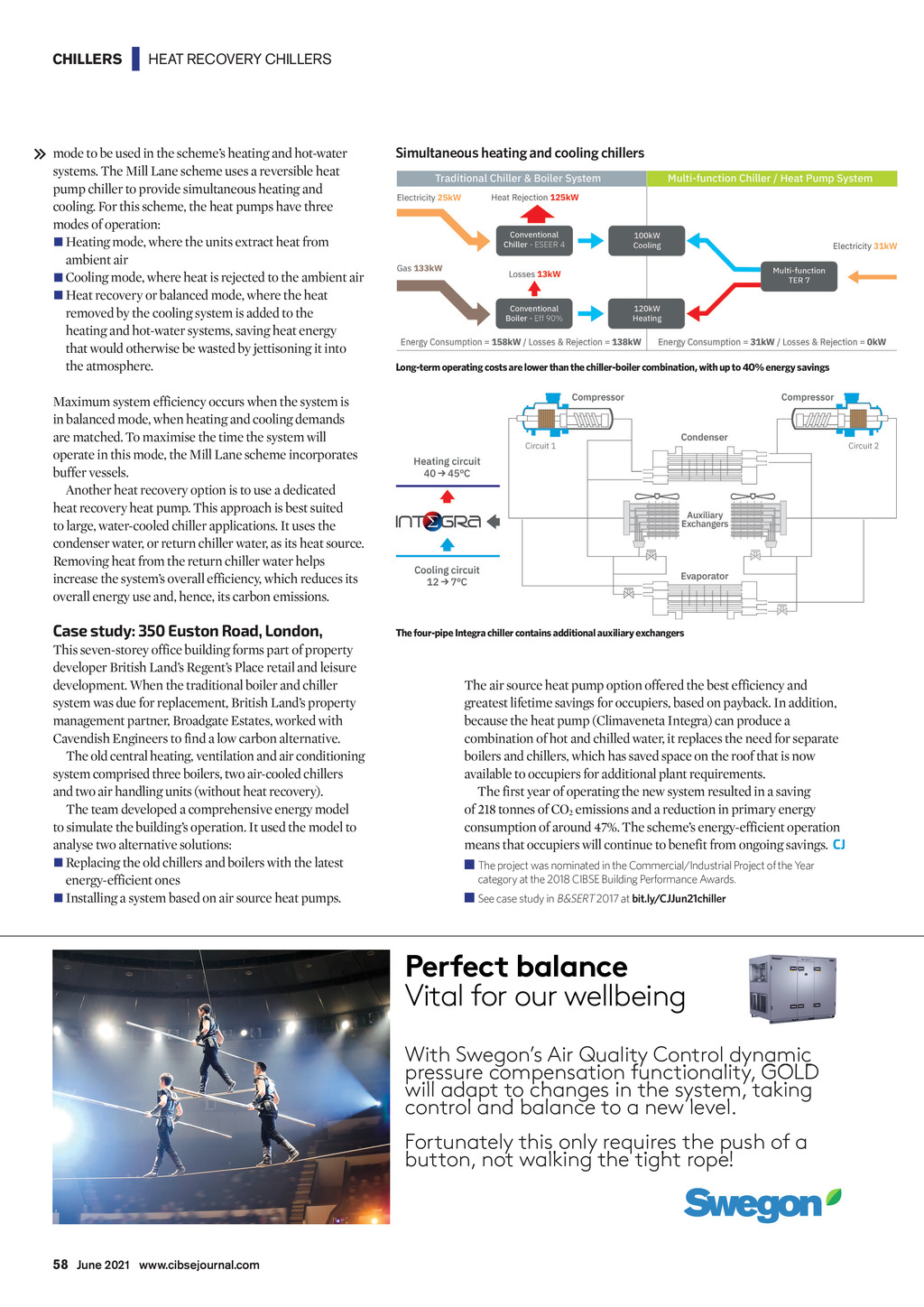

CHILLERS | HEAT RECOVERY CHILLERS mode to be used in the schemes heating and hot-water systems. The Mill Lane scheme uses a reversible heat pump chiller to provide simultaneous heating and cooling. For this scheme, the heat pumps have three modes of operation: Heating mode, where the units extract heat from ambient air Cooling mode, where heat is rejected to the ambient air Heat recovery or balanced mode, where the heat removed by the cooling system is added to the heating and hot-water systems, saving heat energy that would otherwise be wasted by jettisoning it into the atmosphere. Simultaneous heating and cooling chillers Long-term operating costs are lower than the chiller-boiler combination, with up to 40% energy savings Maximum system efficiency occurs when the system is in balanced mode, when heating and cooling demands are matched. To maximise the time the system will operate in this mode, the Mill Lane scheme incorporates buffer vessels. Another heat recovery option is to use a dedicated heat recovery heat pump. This approach is best suited to large, water-cooled chiller applications. It uses the condenser water, or return chiller water, as its heat source. Removing heat from the return chiller water helps increase the systems overall efficiency, which reduces its overall energy use and, hence, its carbon emissions. Case study: 350 Euston Road, London, This seven-storey office building forms part of property developer British Lands Regents Place retail and leisure development. When the traditional boiler and chiller system was due for replacement, British Lands property management partner, Broadgate Estates, worked with Cavendish Engineers to find a low carbon alternative. The old central heating, ventilation and air conditioning system comprised three boilers, two air-cooled chillers and two air handling units (without heat recovery). The team developed a comprehensive energy model to simulate the buildings operation. It used the model to analyse two alternative solutions: Replacing the old chillers and boilers with the latest energy-efficient ones Installing a system based on air source heat pumps. The four-pipe Integra chiller contains additional auxiliary exchangers The air source heat pump option offered the best efficiency and greatest lifetime savings for occupiers, based on payback. In addition, because the heat pump (Climaveneta Integra) can produce a combination of hot and chilled water, it replaces the need for separate boilers and chillers, which has saved space on the roof that is now available to occupiers for additional plant requirements. The first year of operating the new system resulted in a saving of 218 tonnes of CO2 emissions and a reduction in primary energy consumption of around 47%. The schemes energy-efficient operation means that occupiers will continue to benefit from ongoing savings. CJ The project was nominated in the Commercial/Industrial Project of the Year category at the 2018 CIBSE Building Performance Awards. See case study in B&SERT 2017 at bit.ly/CJJun21chiller Vital for our wellbeing With Swegons g Air Qualityy Control dynamic y pressure compensation p p functionality, y, GOLD will adapt p to changes g in the system, y taking control and balance to a new level. Fortunatelyy this onlyy requires q the push p of a button, not walking the tight rope! 58 June 2021 www.cibsejournal.com CIBSE June 21 pp57-58 Heat recovery chiller.indd 58 21/05/2021 16:29