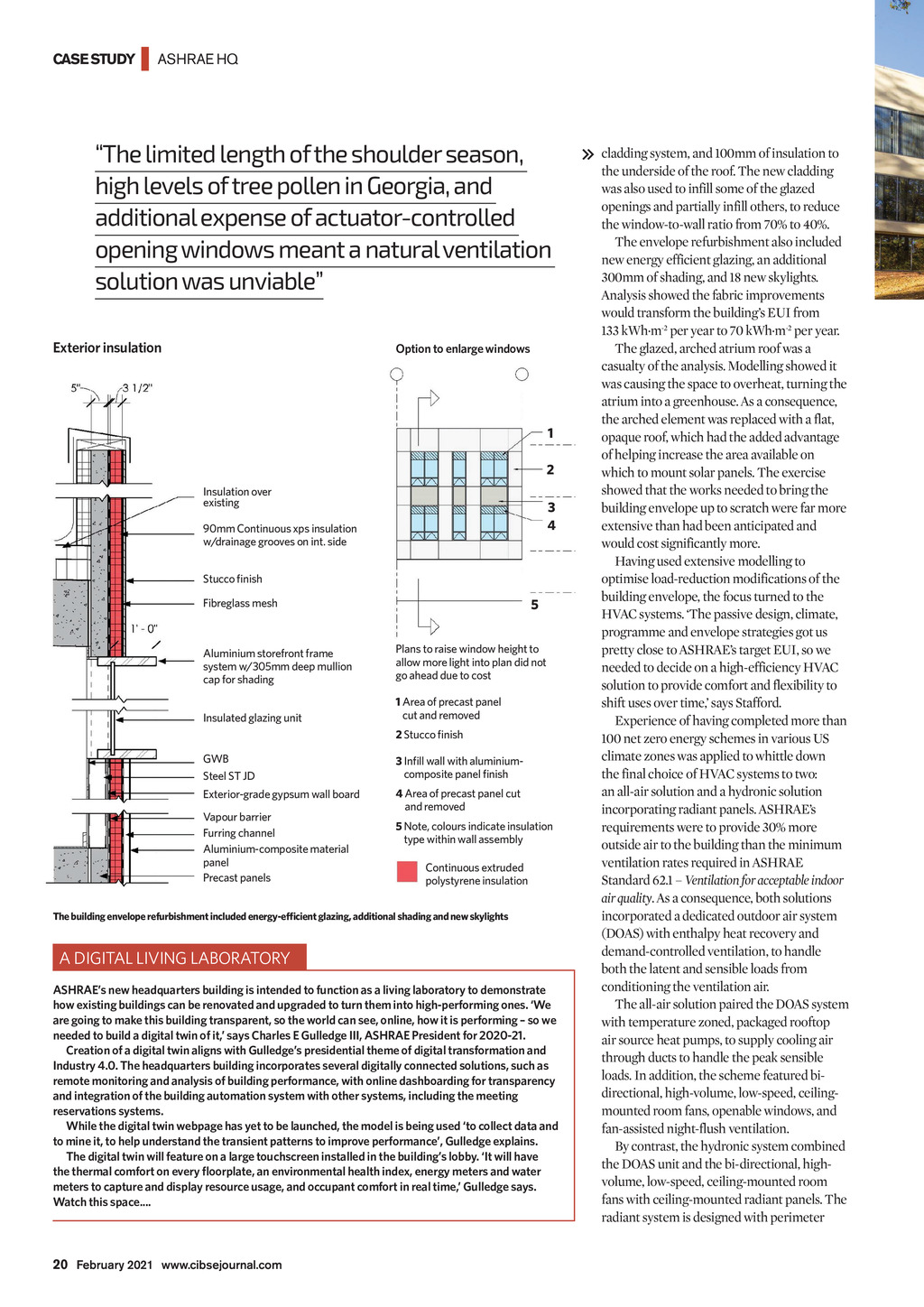

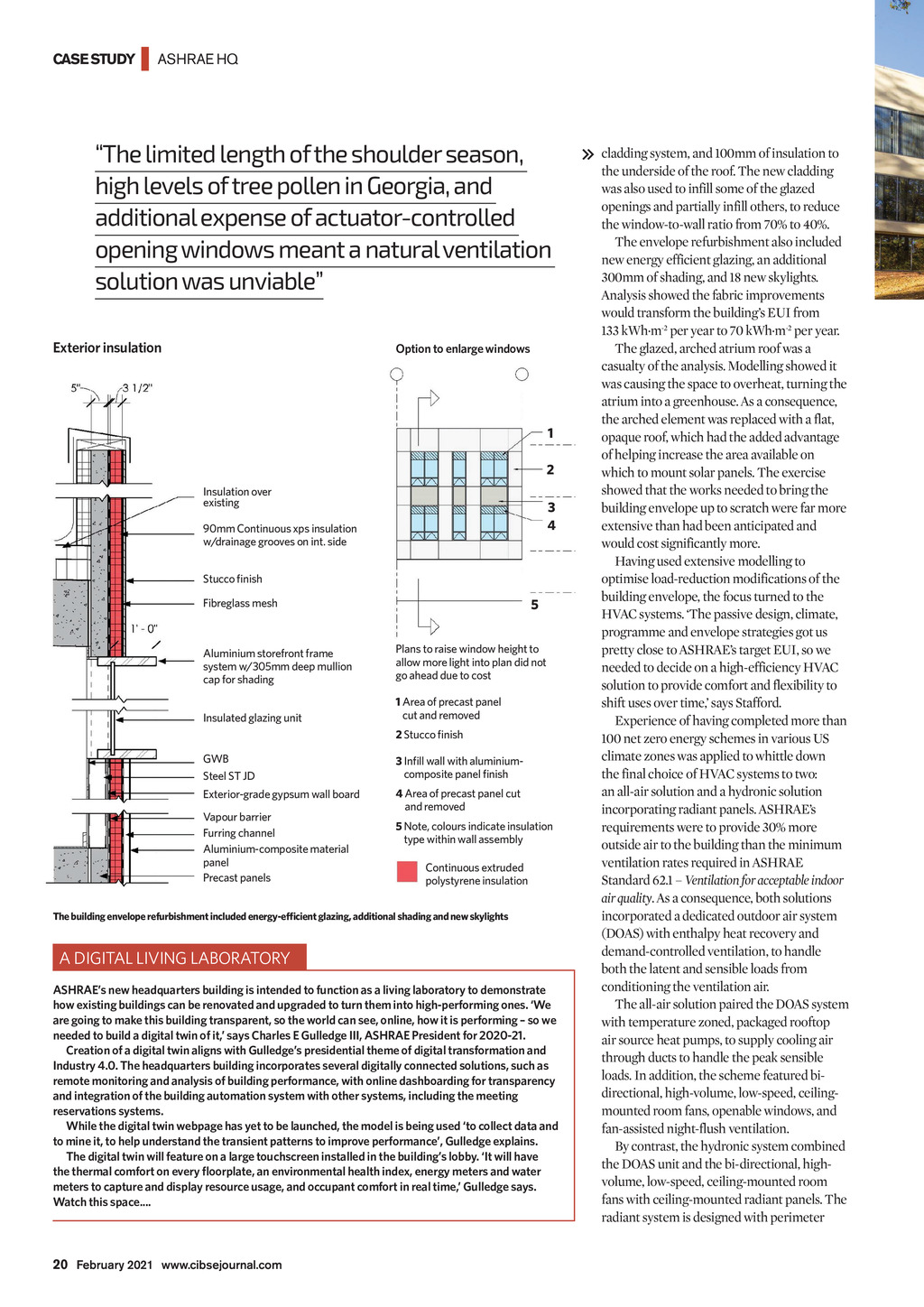

CASE STUDY | ASHRAE HQ The limited length of the shoulder season, high levels of tree pollen in Georgia, and additional expense of actuator-controlled opening windows meant a natural ventilation solution was unviable Exterior insulation Option to enlarge windows 1 2 Insulation over existing 3 4 90mm Continuous xps insulation w/drainage grooves on int. side Stucco finish Fibreglass mesh 5 Aluminium storefront frame system w/305mm deep mullion cap for shading Plans to raise window height to allow more light into plan did not go ahead due to cost Insulated glazing unit 1 Area of precast panel cut and removed 2 Stucco finish GWB Steel ST JD 3 Infill wall with aluminiumcomposite panel finish Exterior-grade gypsum wall board 4 Area of precast panel cut and removed Vapour barrier Furring channel Aluminium-composite material panel Precast panels 5 Note, colours indicate insulation type within wall assembly Continuous extruded polystyrene insulation The building envelope refurbishment included energy-efficient glazing, additional shading and new skylights A DIGITAL LIVING LABORATORY ASHRAEs new headquarters building is intended to function as a living laboratory to demonstrate how existing buildings can be renovated and upgraded to turn them into high-performing ones. We are going to make this building transparent, so the world can see, online, how it is performing so we needed to build a digital twin of it, says Charles E Gulledge III, ASHRAE President for 2020-21. Creation of a digital twin aligns with Gulledges presidential theme of digital transformation and Industry 4.0. The headquarters building incorporates several digitally connected solutions, such as remote monitoring and analysis of building performance, with online dashboarding for transparency and integration of the building automation system with other systems, including the meeting reservations systems. While the digital twin webpage has yet to be launched, the model is being used to collect data and to mine it, to help understand the transient patterns to improve performance, Gulledge explains. The digital twin will feature on a large touchscreen installed in the buildings lobby. It will have the thermal comfort on every floorplate, an environmental health index, energy meters and water meters to capture and display resource usage, and occupant comfort in real time, Gulledge says. Watch this space.... cladding system, and 100mm of insulation to the underside of the roof. The new cladding was also used to infill some of the glazed openings and partially infill others, to reduce the window-to-wall ratio from 70% to 40%. The envelope refurbishment also included new energy efficient glazing, an additional 300mm of shading, and 18 new skylights. Analysis showed the fabric improvements would transform the buildings EUI from 133 kWh.m-2 per year to 70 kWh.m-2 per year. The glazed, arched atrium roof was a casualty of the analysis. Modelling showed it was causing the space to overheat, turning the atrium into a greenhouse. As a consequence, the arched element was replaced with a flat, opaque roof, which had the added advantage of helping increase the area available on which to mount solar panels. The exercise showed that the works needed to bring the building envelope up to scratch were far more extensive than had been anticipated and would cost significantly more. Having used extensive modelling to optimise load-reduction modifications of the building envelope, the focus turned to the HVAC systems. The passive design, climate, programme and envelope strategies got us pretty close to ASHRAEs target EUI, so we needed to decide on a high-efficiency HVAC solution to provide comfort and flexibility to shift uses over time, says Stafford. Experience of having completed more than 100 net zero energy schemes in various US climate zones was applied to whittle down the final choice of HVAC systems to two: an all-air solution and a hydronic solution incorporating radiant panels. ASHRAEs requirements were to provide 30% more outside air to the building than the minimum ventilation rates required in ASHRAE Standard 62.1 Ventilation for acceptable indoor air quality. As a consequence, both solutions incorporated a dedicated outdoor air system (DOAS) with enthalpy heat recovery and demand-controlled ventilation, to handle both the latent and sensible loads from conditioning the ventilation air. The all-air solution paired the DOAS system with temperature zoned, packaged rooftop air source heat pumps, to supply cooling air through ducts to handle the peak sensible loads. In addition, the scheme featured bidirectional, high-volume, low-speed, ceilingmounted room fans, openable windows, and fan-assisted night-flush ventilation. By contrast, the hydronic system combined the DOAS unit and the bi-directional, highvolume, low-speed, ceiling-mounted room fans with ceiling-mounted radiant panels. The radiant system is designed with perimeter 20 February 2021 www.cibsejournal.com CIBSE Feb21 pp18-21 Ashrae HQ.indd 20 22/01/2021 17:50