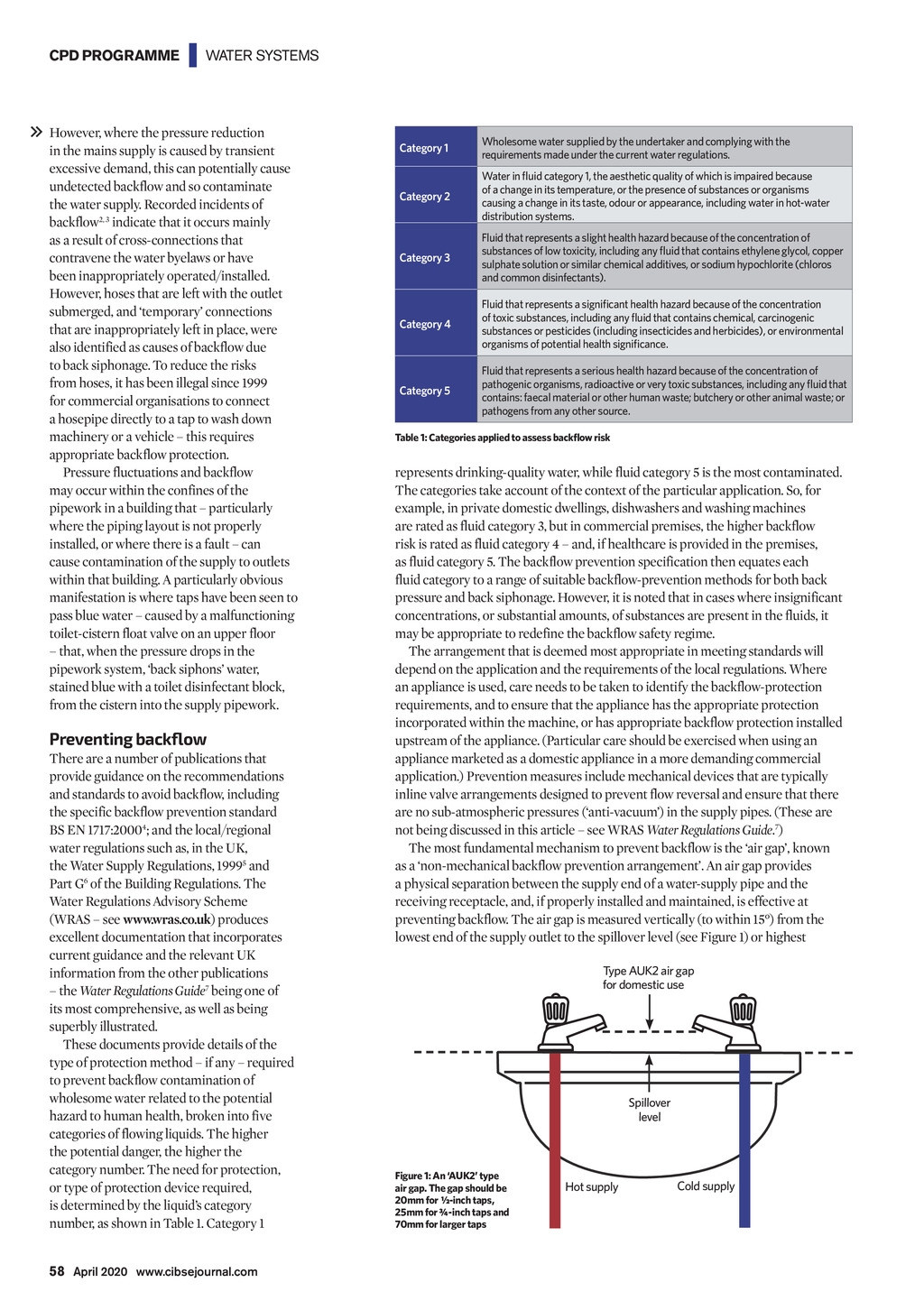

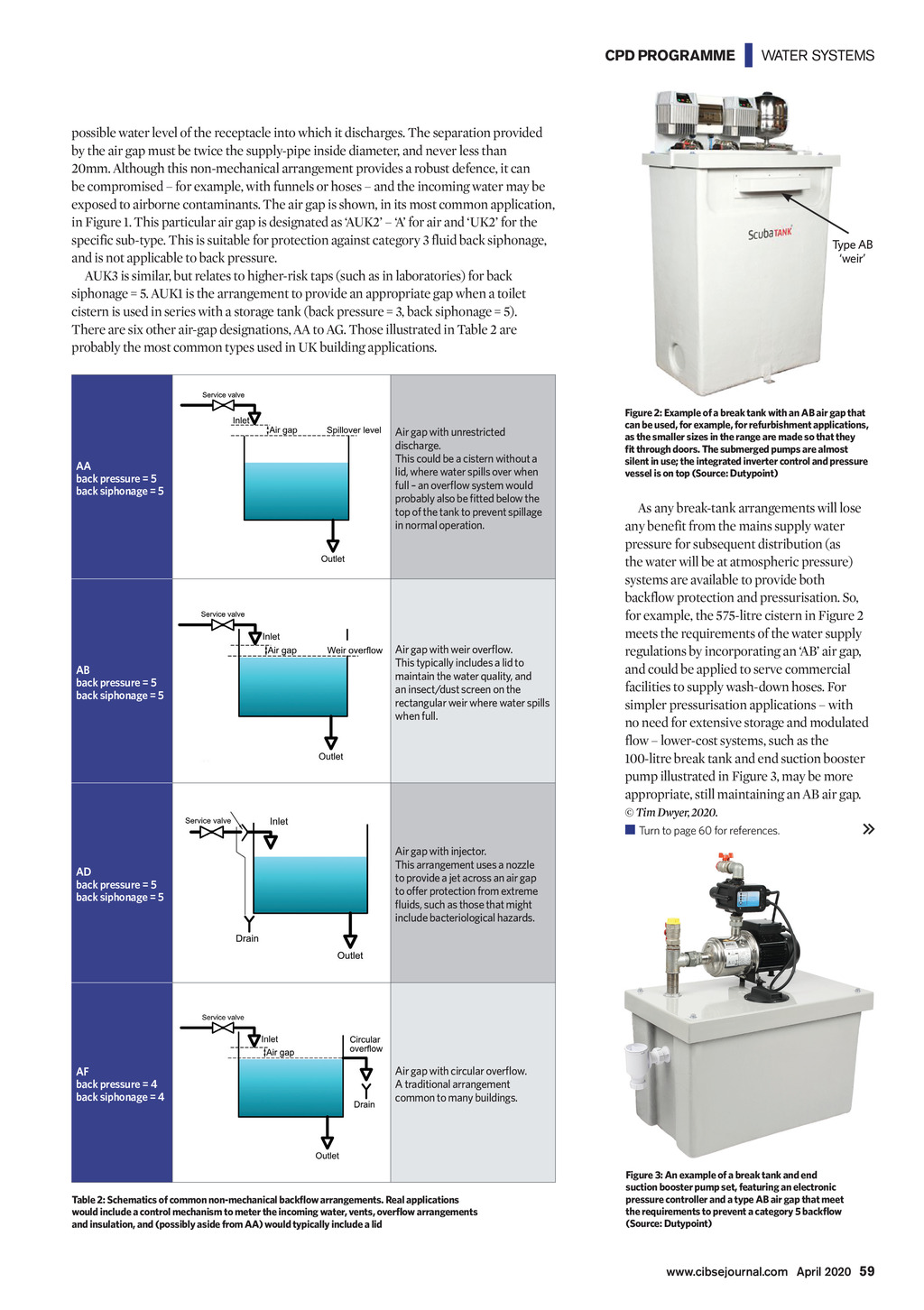

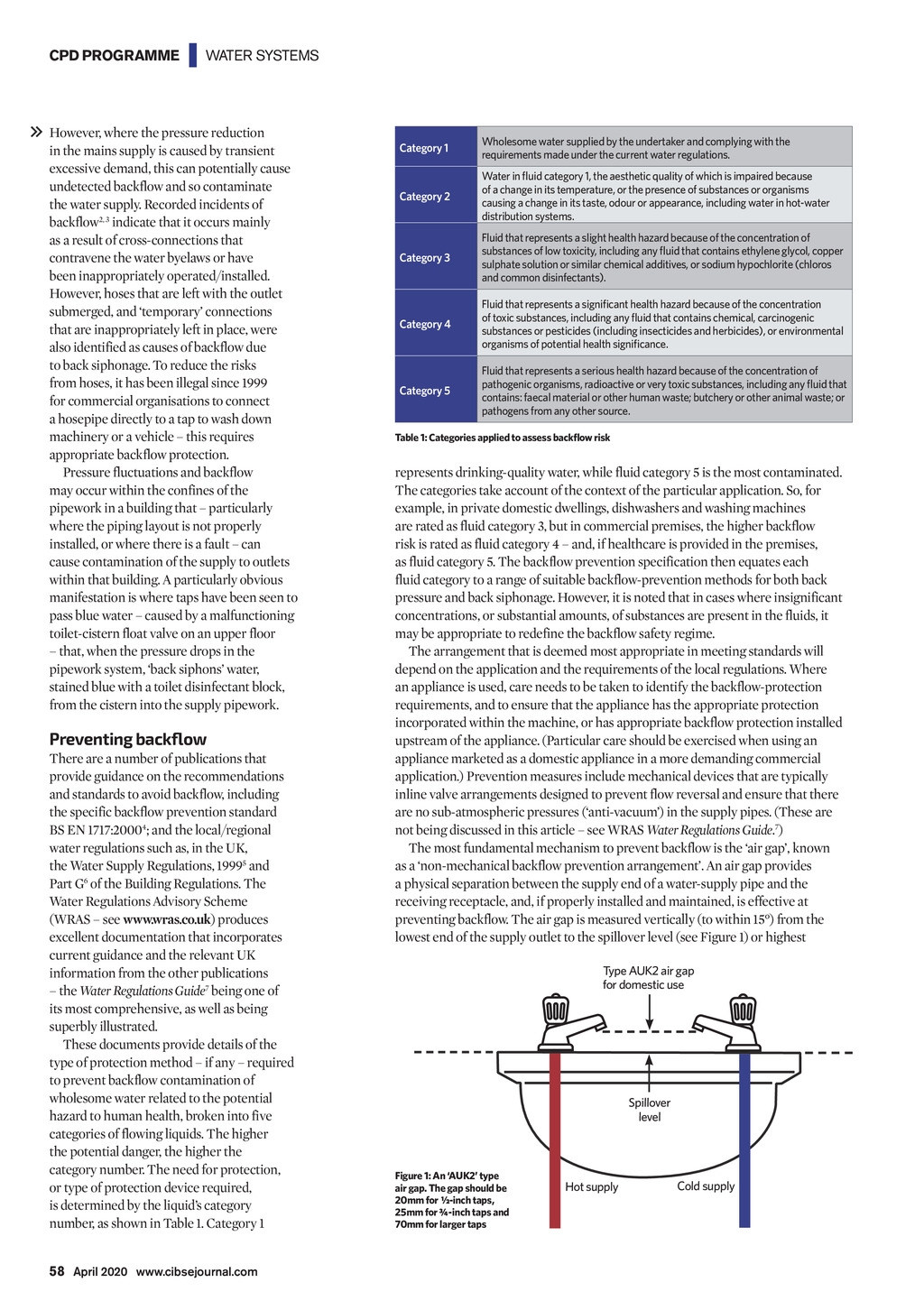

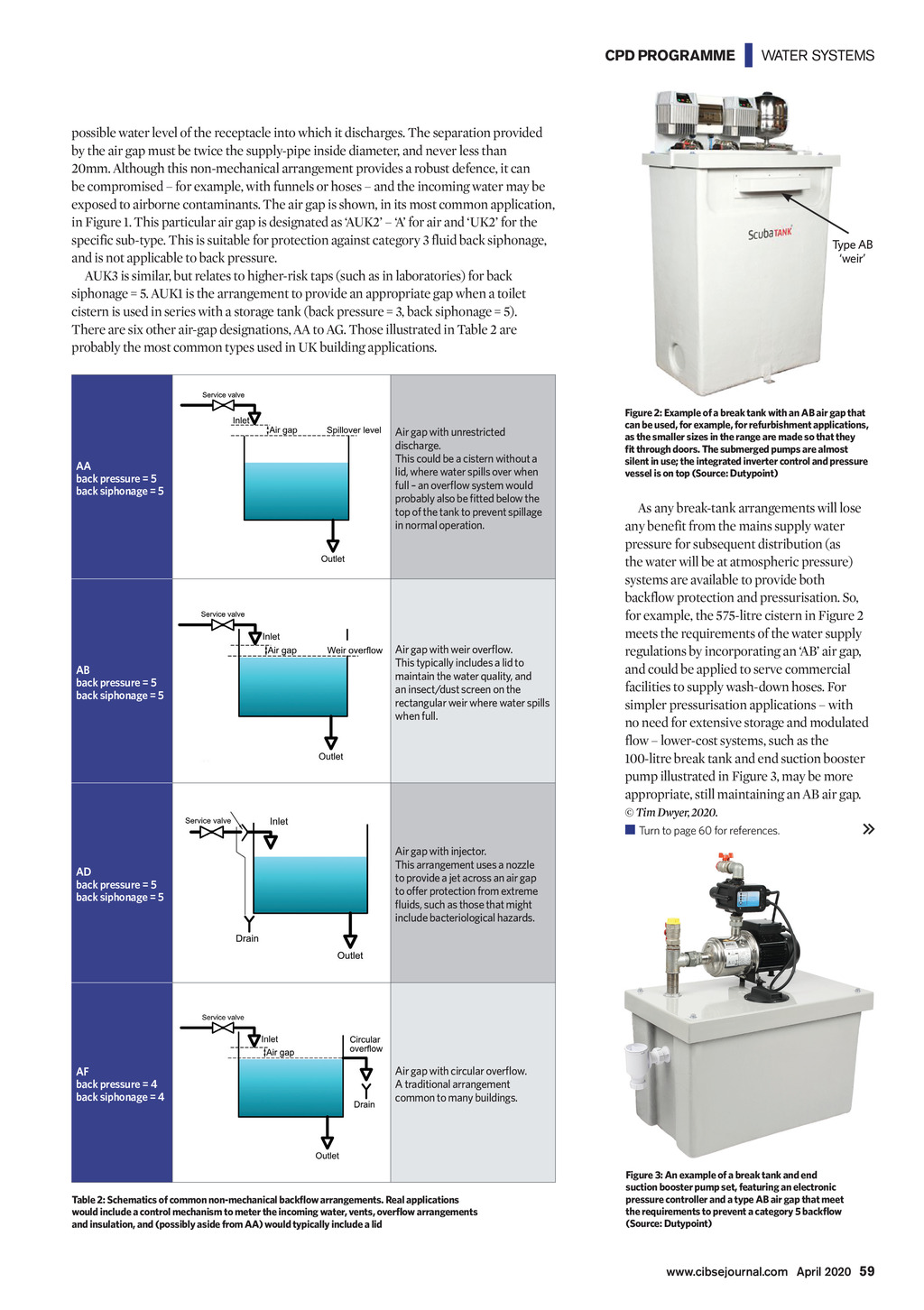

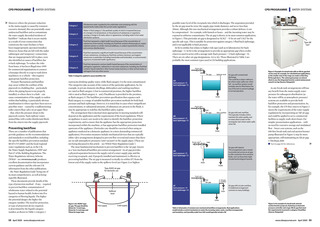

CPD PROGRAMME | WATER SYSTEMS However, where the pressure reduction in the mains supply is caused by transient excessive demand, this can potentially cause undetected backflow and so contaminate the water supply. Recorded incidents of backflow2, 3 indicate that it occurs mainly as a result of cross-connections that contravene the water byelaws or have been inappropriately operated/installed. However, hoses that are left with the outlet submerged, and temporary connections that are inappropriately left in place, were also identified as causes of backflow due to back siphonage. To reduce the risks from hoses, it has been illegal since 1999 for commercial organisations to connect a hosepipe directly to a tap to wash down machinery or a vehicle this requires appropriate backflow protection. Pressure fluctuations and backflow may occur within the confines of the pipework in a building that particularly where the piping layout is not properly installed, or where there is a fault can cause contamination of the supply to outlets within that building. A particularly obvious manifestation is where taps have been seen to pass blue water caused by a malfunctioning toilet-cistern float valve on an upper floor that, when the pressure drops in the pipework system, back siphons water, stained blue with a toilet disinfectant block, from the cistern into the supply pipework. Preventing backflow There are a number of publications that provide guidance on the recommendations and standards to avoid backflow, including the specific backflow prevention standard BS EN 1717:20004; and the local/regional water regulations such as, in the UK, the Water Supply Regulations, 19995 and Part G6 of the Building Regulations. The Water Regulations Advisory Scheme (WRAS see www.wras.co.uk) produces excellent documentation that incorporates current guidance and the relevant UK information from the other publications the Water Regulations Guide7 being one of its most comprehensive, as well as being superbly illustrated. These documents provide details of the type of protection method if any required to prevent backflow contamination of wholesome water related to the potential hazard to human health, broken into five categories of flowing liquids. The higher the potential danger, the higher the category number. The need for protection, or type of protection device required, is determined by the liquids category number, as shown in Table 1. Category 1 Category 1 Wholesome water supplied by the undertaker and complying with the requirements made under the current water regulations. Category 2 Water in fluid category 1, the aesthetic quality of which is impaired because of a change in its temperature, or the presence of substances or organisms causing a change in its taste, odour or appearance, including water in hot-water distribution systems. Category 3 Fluid that represents a slight health hazard because of the concentration of substances of low toxicity, including any fluid that contains ethylene glycol, copper sulphate solution or similar chemical additives, or sodium hypochlorite (chloros and common disinfectants). Category 4 Fluid that represents a significant health hazard because of the concentration of toxic substances, including any fluid that contains chemical, carcinogenic substances or pesticides (including insecticides and herbicides), or environmental organisms of potential health significance. Category 5 Fluid that represents a serious health hazard because of the concentration of pathogenic organisms, radioactive or very toxic substances, including any fluid that contains: faecal material or other human waste; butchery or other animal waste; or pathogens from any other source. Table 1: Categories applied to assess backflow risk represents drinking-quality water, while fluid category 5 is the most contaminated. The categories take account of the context of the particular application. So, for example, in private domestic dwellings, dishwashers and washing machines are rated as fluid category 3, but in commercial premises, the higher backflow risk is rated as fluid category 4 and, if healthcare is provided in the premises, as fluid category 5. The backflow prevention specification then equates each fluid category to a range of suitable backflow-prevention methods for both back pressure and back siphonage. However, it is noted that in cases where insignificant concentrations, or substantial amounts, of substances are present in the fluids, it may be appropriate to redefine the backflow safety regime. The arrangement that is deemed most appropriate in meeting standards will depend on the application and the requirements of the local regulations. Where an appliance is used, care needs to be taken to identify the backflow-protection requirements, and to ensure that the appliance has the appropriate protection incorporated within the machine, or has appropriate backflow protection installed upstream of the appliance. (Particular care should be exercised when using an appliance marketed as a domestic appliance in a more demanding commercial application.) Prevention measures include mechanical devices that are typically inline valve arrangements designed to prevent flow reversal and ensure that there are no sub-atmospheric pressures (anti-vacuum) in the supply pipes. (These are not being discussed in this article see WRAS Water Regulations Guide.7) The most fundamental mechanism to prevent backflow is the air gap, known as a non-mechanical backflow prevention arrangement. An air gap provides a physical separation between the supply end of a water-supply pipe and the receiving receptacle, and, if properly installed and maintained, is effective at preventing backflow. The air gap is measured vertically (to within 15) from the lowest end of the supply outlet to the spillover level (see Figure 1) or highest Type AUK2 air gap for domestic use Spillover level Figure 1: An AUK2 type air gap. The gap should be 20mm for -inch taps, 25mm for -inch taps and 70mm for larger taps Hot supply Cold supply 58 April 2020 www.cibsejournal.com CIBSE Apr20 pp57-60 CPD v3.indd 58 20/03/2020 16:30