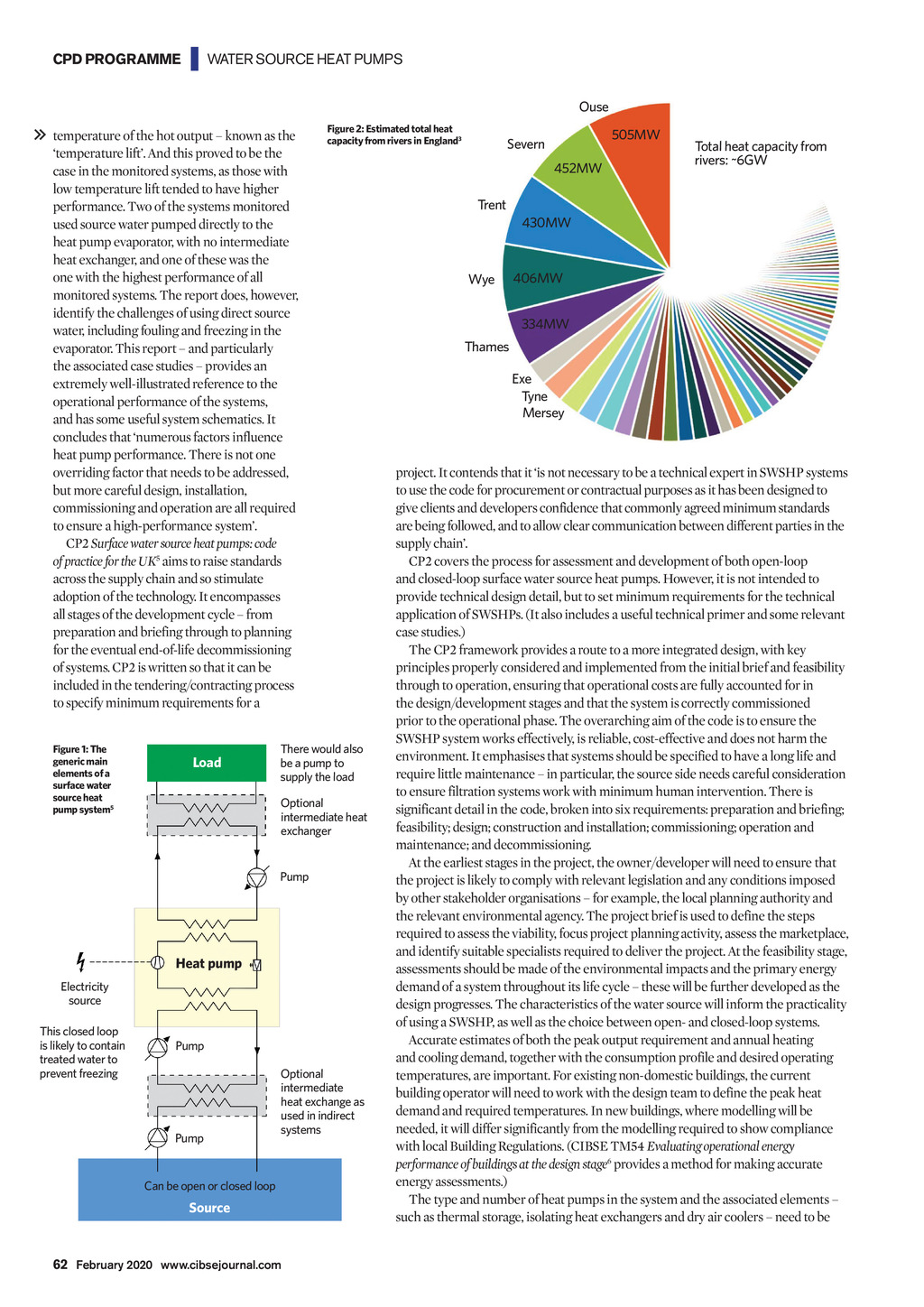

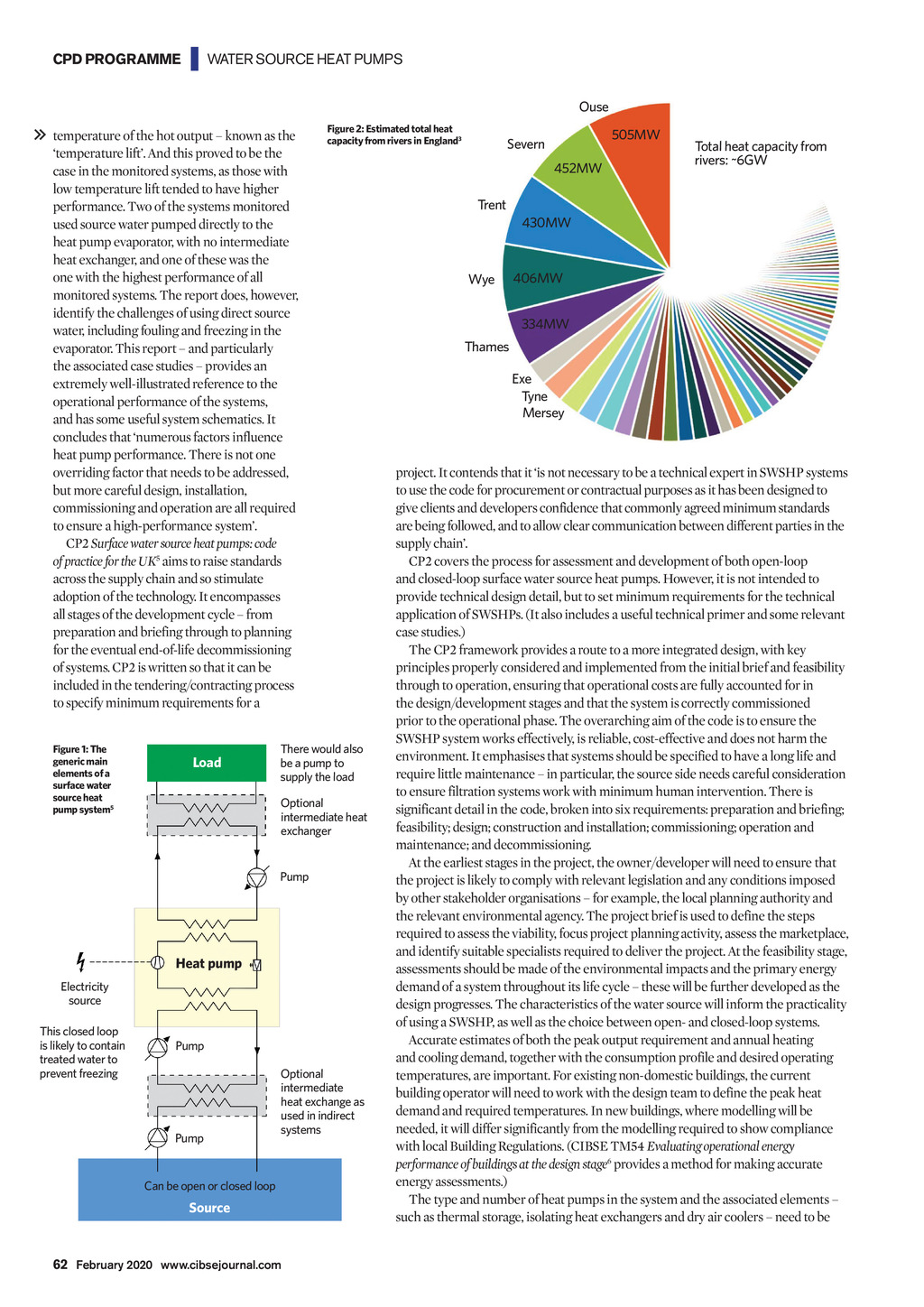

CPD PROGRAMME | WATER SOURCE HEAT PUMPS Ouse temperature of the hot output known as the temperature lift. And this proved to be the case in the monitored systems, as those with low temperature lift tended to have higher performance. Two of the systems monitored used source water pumped directly to the heat pump evaporator, with no intermediate heat exchanger, and one of these was the one with the highest performance of all monitored systems. The report does, however, identify the challenges of using direct source water, including fouling and freezing in the evaporator. This report and particularly the associated case studies provides an extremely well-illustrated reference to the operational performance of the systems, and has some useful system schematics. It concludes that numerous factors influence heat pump performance. There is not one overriding factor that needs to be addressed, but more careful design, installation, commissioning and operation are all required to ensure a high-performance system. CP2 Surface water source heat pumps: code of practice for the UK5 aims to raise standards across the supply chain and so stimulate adoption of the technology. It encompasses all stages of the development cycle from preparation and briefing through to planning for the eventual end-of-life decommissioning of systems. CP2 is written so that it can be included in the tendering/contracting process to specify minimum requirements for a Figure 1: The generic main elements of a surface water source heat pump system5 Load Figure 2: Estimated total heat capacity from rivers in England3 There would also be a pump to supply the load Optional intermediate heat exchanger Pump Heat pump Electricity source This closed loop is likely to contain treated water to prevent freezing Pump Pump Optional intermediate heat exchange as used in indirect systems Can be open or closed loop Source 505MW Severn 452MW Total heat capacity from rivers: 6GW Trent 430MW Wye 406MW 334MW Thames Exe Tyne Mersey project. It contends that it is not necessary to be a technical expert in SWSHP systems to use the code for procurement or contractual purposes as it has been designed to give clients and developers confidence that commonly agreed minimum standards are being followed, and to allow clear communication between different parties in the supply chain. CP2 covers the process for assessment and development of both open-loop and closed-loop surface water source heat pumps. However, it is not intended to provide technical design detail, but to set minimum requirements for the technical application of SWSHPs. (It also includes a useful technical primer and some relevant case studies.) The CP2 framework provides a route to a more integrated design, with key principles properly considered and implemented from the initial brief and feasibility through to operation, ensuring that operational costs are fully accounted for in the design/development stages and that the system is correctly commissioned prior to the operational phase. The overarching aim of the code is to ensure the SWSHP system works effectively, is reliable, cost-effective and does not harm the environment. It emphasises that systems should be specified to have a long life and require little maintenance in particular, the source side needs careful consideration to ensure filtration systems work with minimum human intervention. There is significant detail in the code, broken into six requirements: preparation and briefing; feasibility; design; construction and installation; commissioning; operation and maintenance; and decommissioning. At the earliest stages in the project, the owner/developer will need to ensure that the project is likely to comply with relevant legislation and any conditions imposed by other stakeholder organisations for example, the local planning authority and the relevant environmental agency. The project brief is used to define the steps required to assess the viability, focus project planning activity, assess the marketplace, and identify suitable specialists required to deliver the project. At the feasibility stage, assessments should be made of the environmental impacts and the primary energy demand of a system throughout its life cycle these will be further developed as the design progresses. The characteristics of the water source will inform the practicality of using a SWSHP, as well as the choice between open- and closed-loop systems. Accurate estimates of both the peak output requirement and annual heating and cooling demand, together with the consumption profile and desired operating temperatures, are important. For existing non-domestic buildings, the current building operator will need to work with the design team to define the peak heat demand and required temperatures. In new buildings, where modelling will be needed, it will differ significantly from the modelling required to show compliance with local Building Regulations. (CIBSE TM54 Evaluating operational energy performance of buildings at the design stage6 provides a method for making accurate energy assessments.) The type and number of heat pumps in the system and the associated elements such as thermal storage, isolating heat exchangers and dry air coolers need to be 62 February 2020 www.cibsejournal.com CIBSE Feb20 pp61-64 CPD v3.indd 62 24/01/2020 15:13