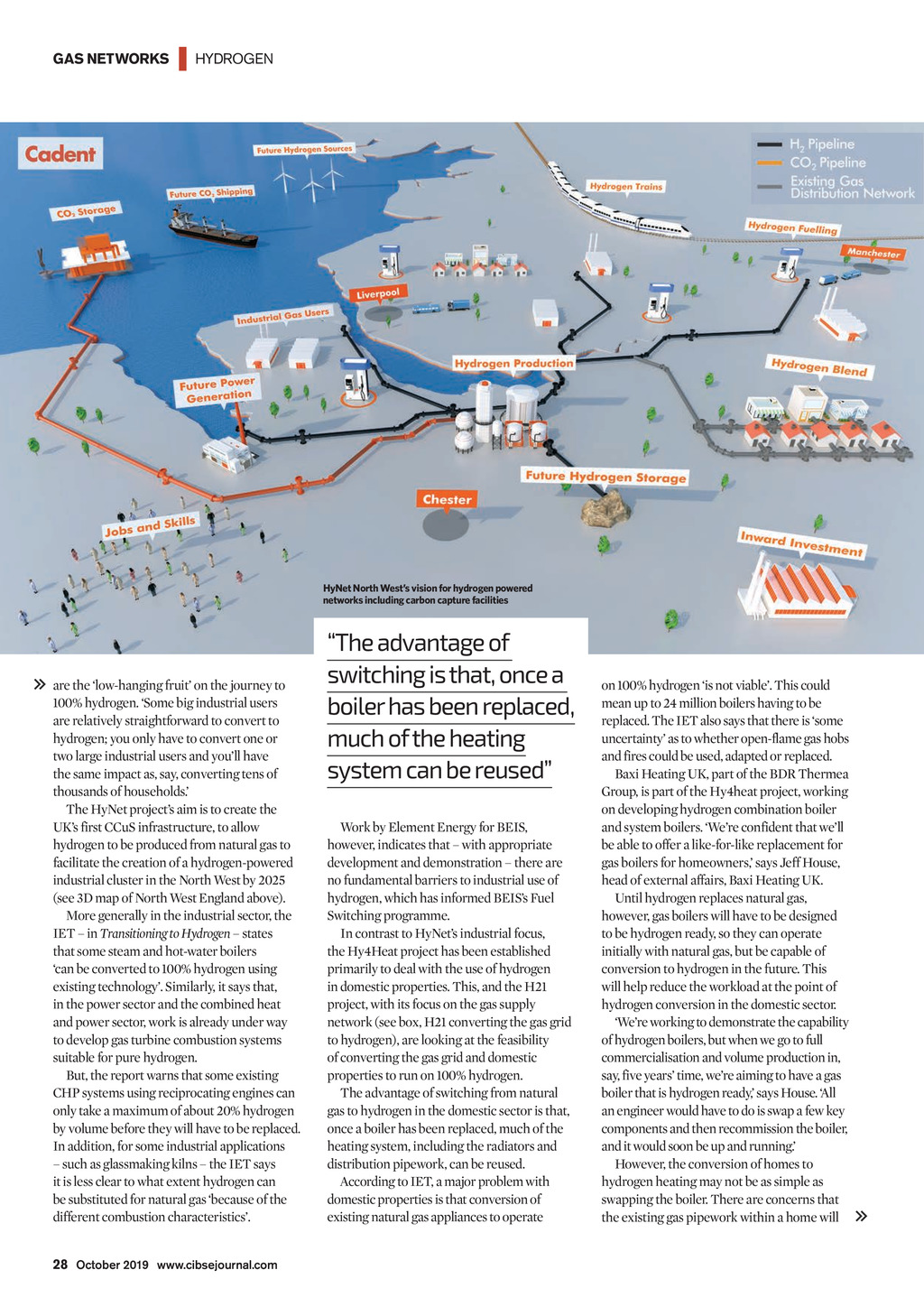

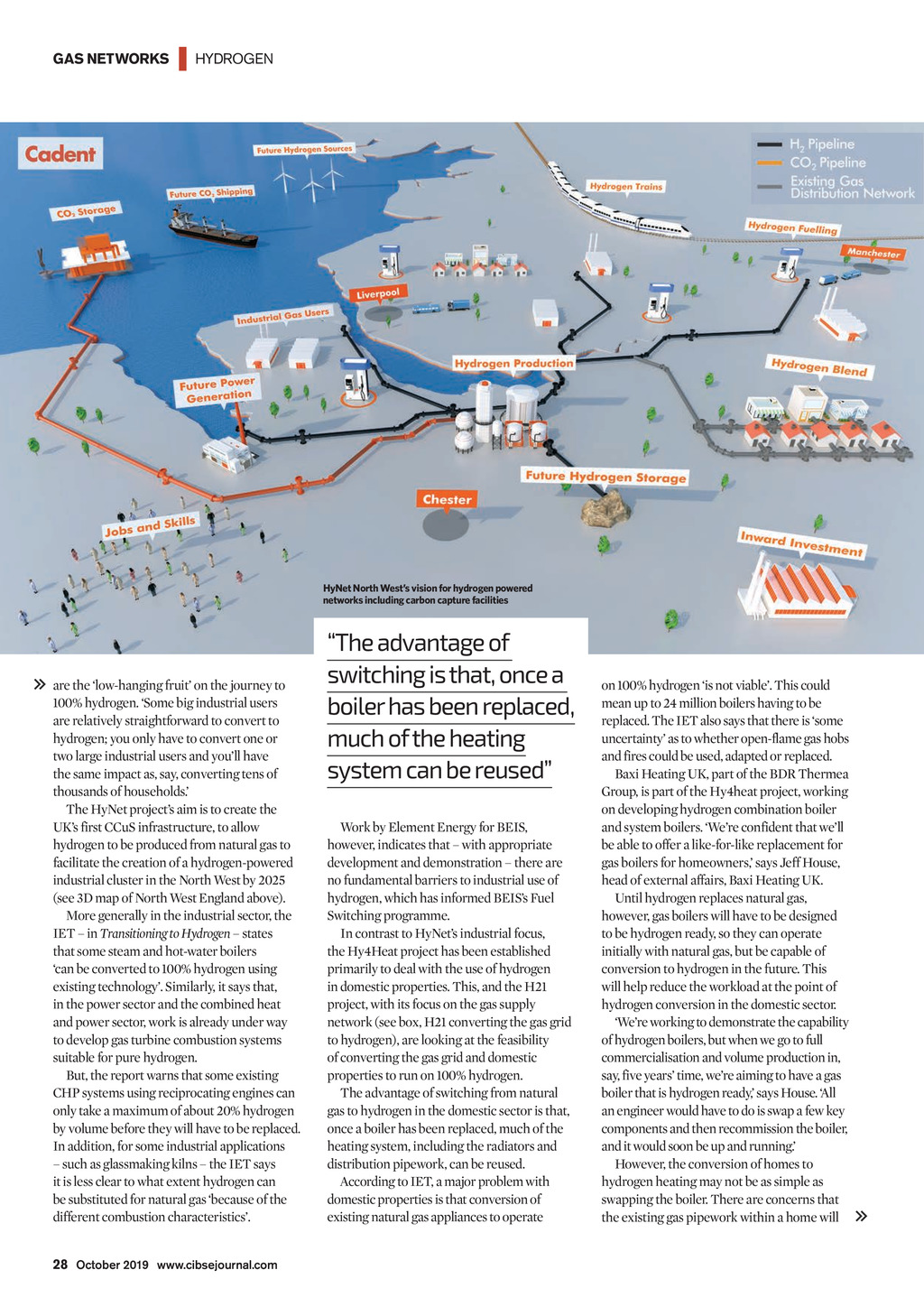

GAS NETWORKS | HYDROGEN HyNet North Wests vision for hydrogen powered networks including carbon capture facilities are the low-hanging fruit on the journey to 100% hydrogen. Some big industrial users are relatively straightforward to convert to hydrogen; you only have to convert one or two large industrial users and youll have the same impact as, say, converting tens of thousands of households. The HyNet projects aim is to create the UKs first CCuS infrastructure, to allow hydrogen to be produced from natural gas to facilitate the creation of a hydrogen-powered industrial cluster in the North West by 2025 (see 3D map of North West England above). More generally in the industrial sector, the IET in Transitioning to Hydrogen states that some steam and hot-water boilers can be converted to 100% hydrogen using existing technology. Similarly, it says that, in the power sector and the combined heat and power sector, work is already under way to develop gas turbine combustion systems suitable for pure hydrogen. But, the report warns that some existing CHP systems using reciprocating engines can only take a maximum of about 20% hydrogen by volume before they will have to be replaced. In addition, for some industrial applications such as glassmaking kilns the IET says it is less clear to what extent hydrogen can be substituted for natural gas because of the different combustion characteristics. The advantage of switching is that, once a boiler has been replaced, much of the heating system can be reused Work by Element Energy for BEIS, however, indicates that with appropriate development and demonstration there are no fundamental barriers to industrial use of hydrogen, which has informed BEISs Fuel Switching programme. In contrast to HyNets industrial focus, the Hy4Heat project has been established primarily to deal with the use of hydrogen in domestic properties. This, and the H21 project, with its focus on the gas supply network (see box, H21 converting the gas grid to hydrogen), are looking at the feasibility of converting the gas grid and domestic properties to run on 100% hydrogen. The advantage of switching from natural gas to hydrogen in the domestic sector is that, once a boiler has been replaced, much of the heating system, including the radiators and distribution pipework, can be reused. According to IET, a major problem with domestic properties is that conversion of existing natural gas appliances to operate on 100% hydrogen is not viable. This could mean up to 24 million boilers having to be replaced. The IET also says that there is some uncertainty as to whether open-flame gas hobs and fires could be used, adapted or replaced. Baxi Heating UK, part of the BDR Thermea Group, is part of the Hy4heat project, working on developing hydrogen combination boiler and system boilers. Were confident that well be able to offer a like-for-like replacement for gas boilers for homeowners, says Jeff House, head of external affairs, Baxi Heating UK. Until hydrogen replaces natural gas, however, gas boilers will have to be designed to be hydrogen ready, so they can operate initially with natural gas, but be capable of conversion to hydrogen in the future. This will help reduce the workload at the point of hydrogen conversion in the domestic sector. Were working to demonstrate the capability of hydrogen boilers, but when we go to full commercialisation and volume production in, say, five years time, were aiming to have a gas boiler that is hydrogen ready, says House. All an engineer would have to do is swap a few key components and then recommission the boiler, and it would soon be up and running. However, the conversion of homes to hydrogen heating may not be as simple as swapping the boiler. There are concerns that the existing gas pipework within a home will 28 October 2019 www.cibsejournal.com CIBSE Oct19 pp26-28, 30 Hydrogen.indd 28 20/09/2019 16:45