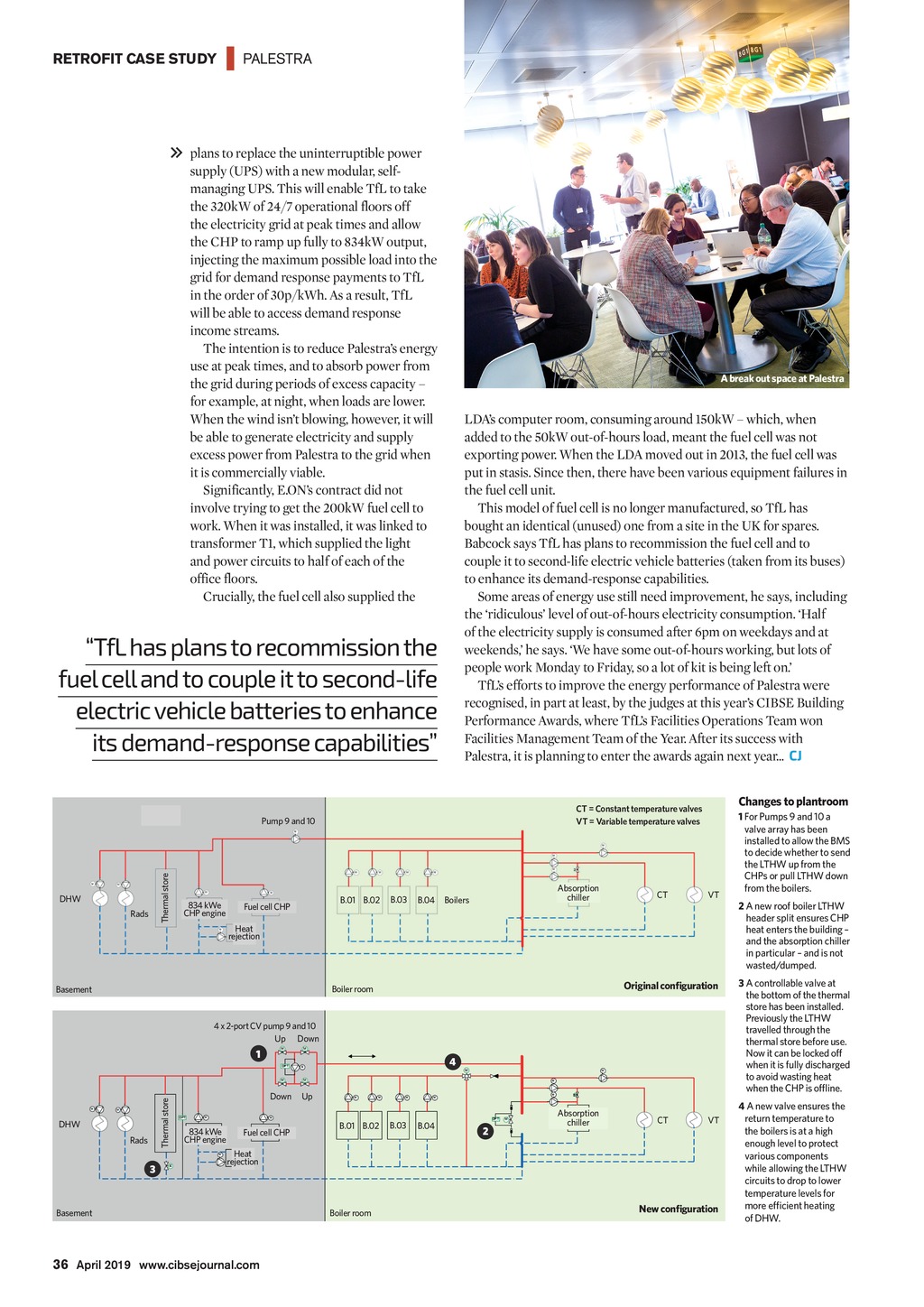

RETROFIT CASE STUDY | PALESTRA plans to replace the uninterruptible power supply (UPS) with a new modular, selfmanaging UPS. This will enable TfL to take the 320kW of 24/7 operational floors off the electricity grid at peak times and allow the CHP to ramp up fully to 834kW output, injecting the maximum possible load into the grid for demand response payments to TfL in the order of 30p/kWh. As a result, TfL will be able to access demand response income streams. The intention is to reduce Palestras energy use at peak times, and to absorb power from the grid during periods of excess capacity for example, at night, when loads are lower. When the wind isnt blowing, however, it will be able to generate electricity and supply excess power from Palestra to the grid when it is commercially viable. Significantly, E.ONs contract did not involve trying to get the 200kW fuel cell to work. When it was installed, it was linked to transformer T1, which supplied the light and power circuits to half of each of the office floors. Crucially, the fuel cell also supplied the A break out space at Palestra LDAs computer room, consuming around 150kW which, when added to the 50kW out-of-hours load, meant the fuel cell was not exporting power. When the LDA moved out in 2013, the fuel cell was putin stasis. Since then, there have been various equipment failures in the fuel cell unit. This model of fuel cell is no longer manufactured, so TfL has bought an identical (unused) one from a site in the UK for spares. Babcock says TfL has plans to recommission the fuel cell and to couple it to second-life electric vehicle batteries (taken from its buses) to enhance its demand-response capabilities. Some areas of energy use still need improvement, he says, including the ridiculous level of out-of-hours electricity consumption. Half of the electricity supply is consumed after 6pm on weekdays and at weekends, he says. We have some out-of-hours working, but lots of people work Monday to Friday, so a lot of kit is being left on. TfLs efforts to improve the energy performance of Palestra were recognised, in part at least, by the judges at this years CIBSE Building Performance Awards, where TfLs Facilities Operations Team won Facilities Management Team of the Year. After its success with Palestra, it is planning to enter the awards again next year... CJ TfL has plans to recommission the fuel cell and to couple it to second-life electric vehicle batteries to enhance its demand-response capabilities Thermal store DHW Rads 834 kWe CHP engine B.01 B.02 Fuel cell CHP Changes to plantroom CT = Constant temperature valves VT = Variable temperature valves Pump 9 and 10 B.03 B.04 Absorption chiller Boilers CT VT Heat rejection Original configuration Boiler room Basement 4 x 2-port CV pump 9 and 10 Up Down Thermal store 1 DHW Rads 3 4 Down 834 kWe CHP engine Fuel cell CHP Up B.01 B.02 B.03 B.04 2 Absorption chiller CT VT Heat rejection Basement Boiler room New configuration 1 For Pumps 9 and 10 a valve array has been installed to allow the BMS to decide whether to send the LTHW up from the CHPs or pull LTHW down from the boilers. 2A new roof boiler LTHW header split ensures CHP heat enters the building and the absorption chiller in particular and is not wasted/dumped. 3A controllable valve at the bottom of the thermal store has been installed. Previously the LTHW travelled through the thermal store before use. Now it can be locked off when it is fully discharged to avoid wasting heat when the CHP is offline. 4A new valve ensures the return temperature to the boilers is at a high enough level to protect various components while allowing the LTHW circuits to drop to lower temperature levels for more efficient heating of DHW. 36 April 2019 www.cibsejournal.com CIBSE Apr19 pp32-36 Palestra.indd 36 22/03/2019 16:55