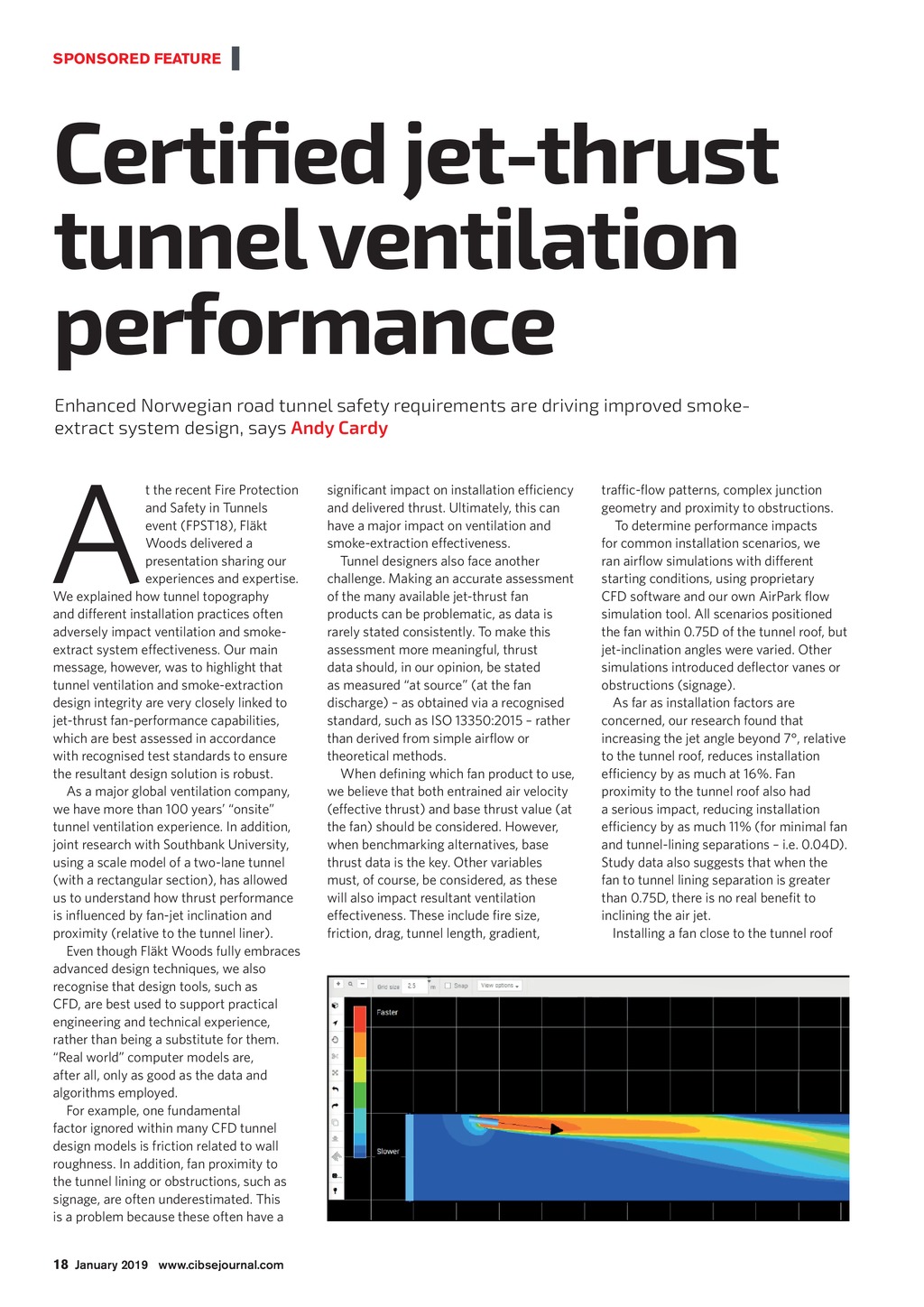

SPONSORED FEATURE | Certied jet-thrust tunnel ventilation performance Enhanced Norwegian road tunnel safety requirements are driving improved smokeextract system design, says Andy Cardy A t the recent Fire Protection and Safety in Tunnels event (FPST18), Flkt Woods delivered a presentation sharing our experiences and expertise. We explained how tunnel topography and different installation practices often adversely impact ventilation and smokeextract system effectiveness. Our main message, however, was to highlight that tunnel ventilation and smoke-extraction design integrity are very closely linked to jet-thrust fan-performance capabilities, which are best assessed in accordance with recognised test standards to ensure the resultant design solution is robust. As a major global ventilation company, we have more than 100 years onsite tunnel ventilation experience. In addition, joint research with Southbank University, using a scale model of a two-lane tunnel (with a rectangular section), has allowed us to understand how thrust performance is inuenced by fan-jet inclination and proximity (relative to the tunnel liner). Even though Flkt Woods fully embraces advanced design techniques, we also recognise that design tools, such as CFD, are best used to support practical engineering and technical experience, rather than being a substitute for them. Real world computer models are, after all, only as good as the data and algorithms employed. For example, one fundamental factor ignored within many CFD tunnel design models is friction related to wall roughness. In addition, fan proximity to the tunnel lining or obstructions, such as signage, are often underestimated. This is a problem because these often have a signicant impact on installation efciency and delivered thrust. Ultimately, this can have a major impact on ventilation and smoke-extraction effectiveness. Tunnel designers also face another challenge. Making an accurate assessment of the many available jet-thrust fan products can be problematic, as data is rarely stated consistently. To make this assessment more meaningful, thrust data should, in our opinion, be stated as measured at source (at the fan discharge) as obtained via a recognised standard, such as ISO 13350:2015 rather than derived from simple airow or theoretical methods. When dening which fan product to use, we believe that both entrained air velocity (effective thrust) and base thrust value (at the fan) should be considered. However, when benchmarking alternatives, base thrust data is the key. Other variables must, of course, be considered, as these will also impact resultant ventilation effectiveness. These include re size, friction, drag, tunnel length, gradient, trafc-ow patterns, complex junction geometry and proximity to obstructions. To determine performance impacts for common installation scenarios, we ran airow simulations with different starting conditions, using proprietary CFD software and our own AirPark ow simulation tool. All scenarios positioned the fan within 0.75D of the tunnel roof, but jet-inclination angles were varied. Other simulations introduced deector vanes or obstructions (signage). As far as installation factors are concerned, our research found that increasing the jet angle beyond 7, relative to the tunnel roof, reduces installation efciency by as much at 16%. Fan proximity to the tunnel roof also had a serious impact, reducing installation efciency by as much 11% (for minimal fan and tunnel-lining separations i.e. 0.04D). Study data also suggests that when the fan to tunnel lining separation is greater than 0.75D, there is no real benet to inclining the air jet. Installing a fan close to the tunnel roof 18 January 2019 www.cibsejournal.com Flakt DPS Adv.indd 18 18/12/2018 08:59