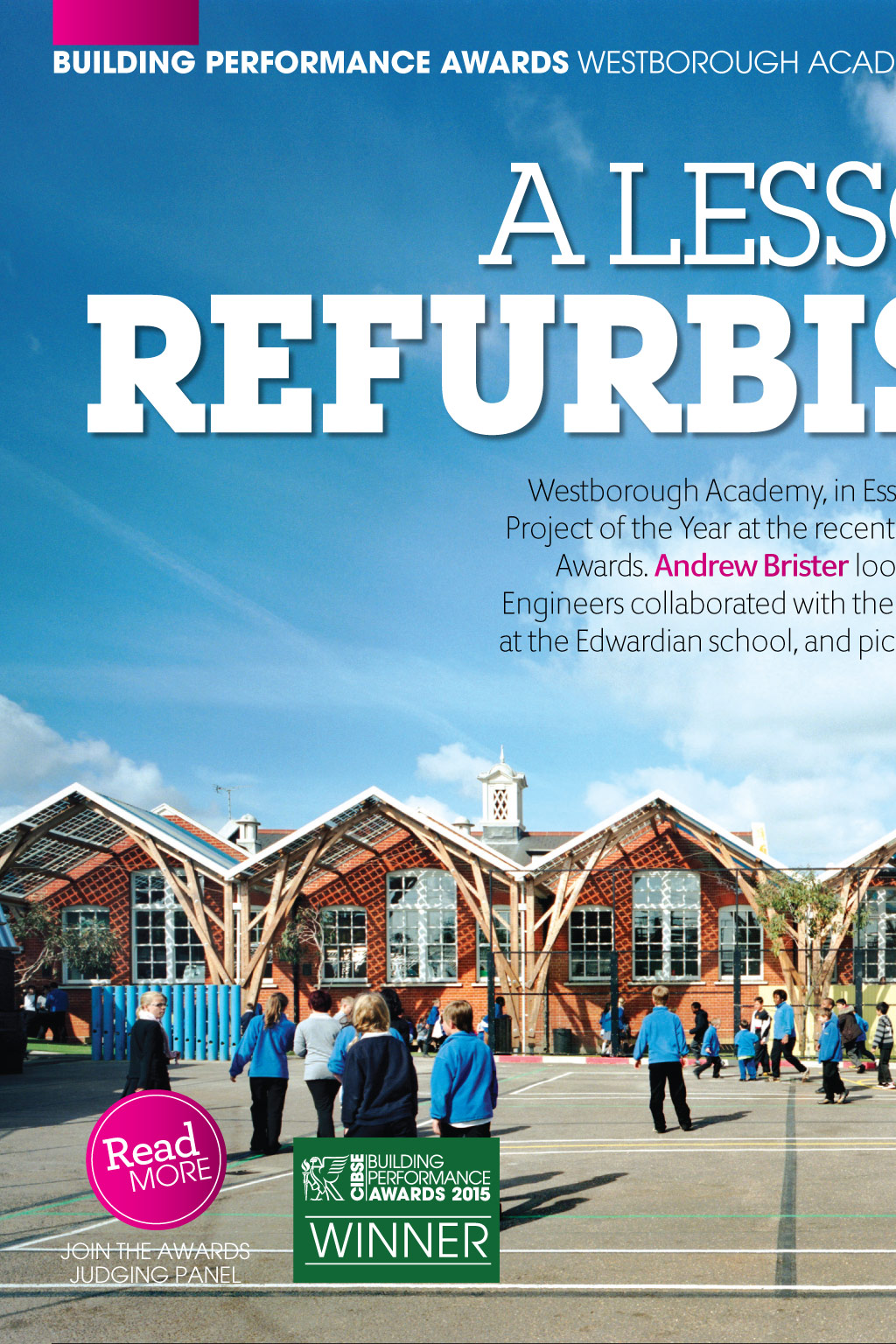

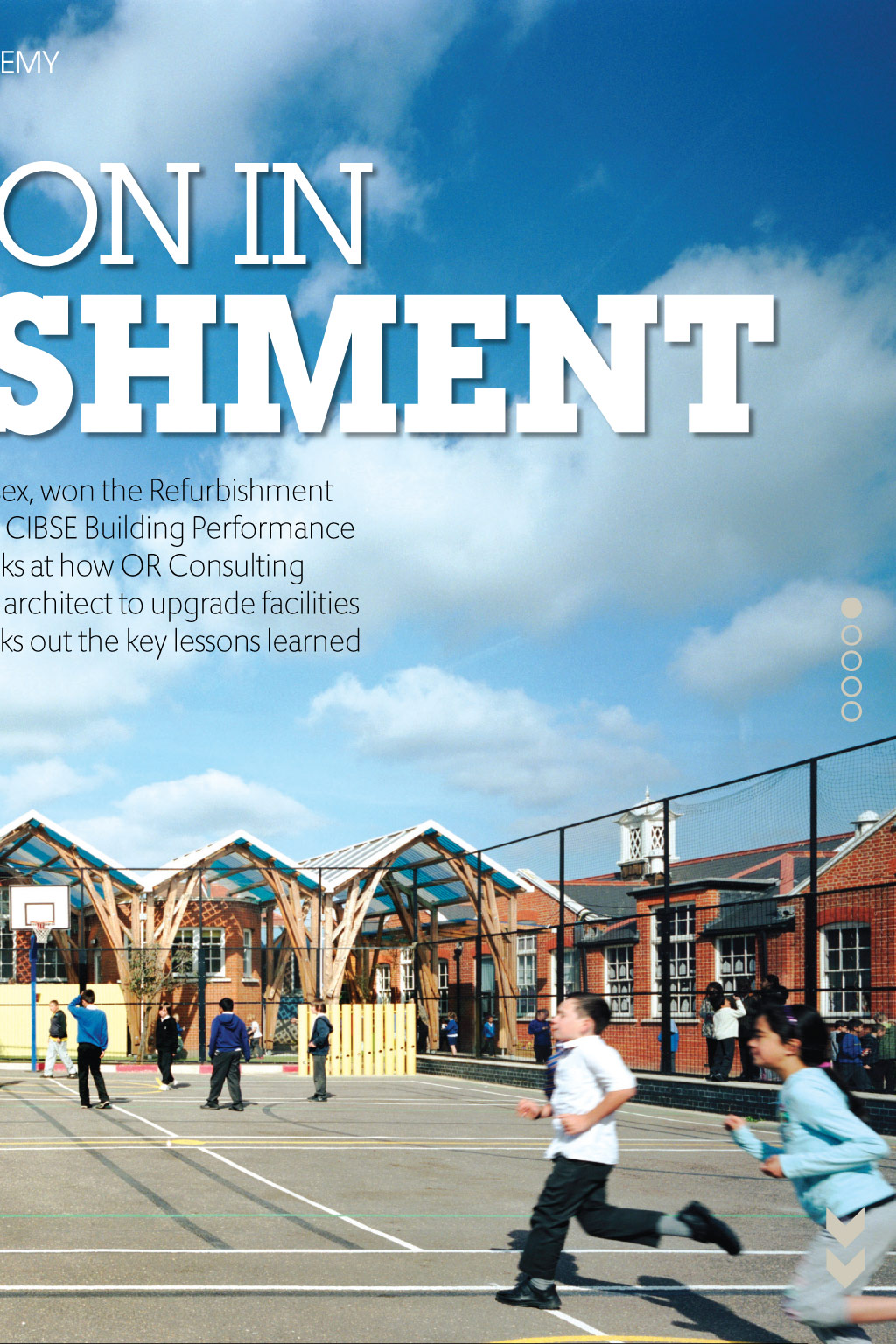

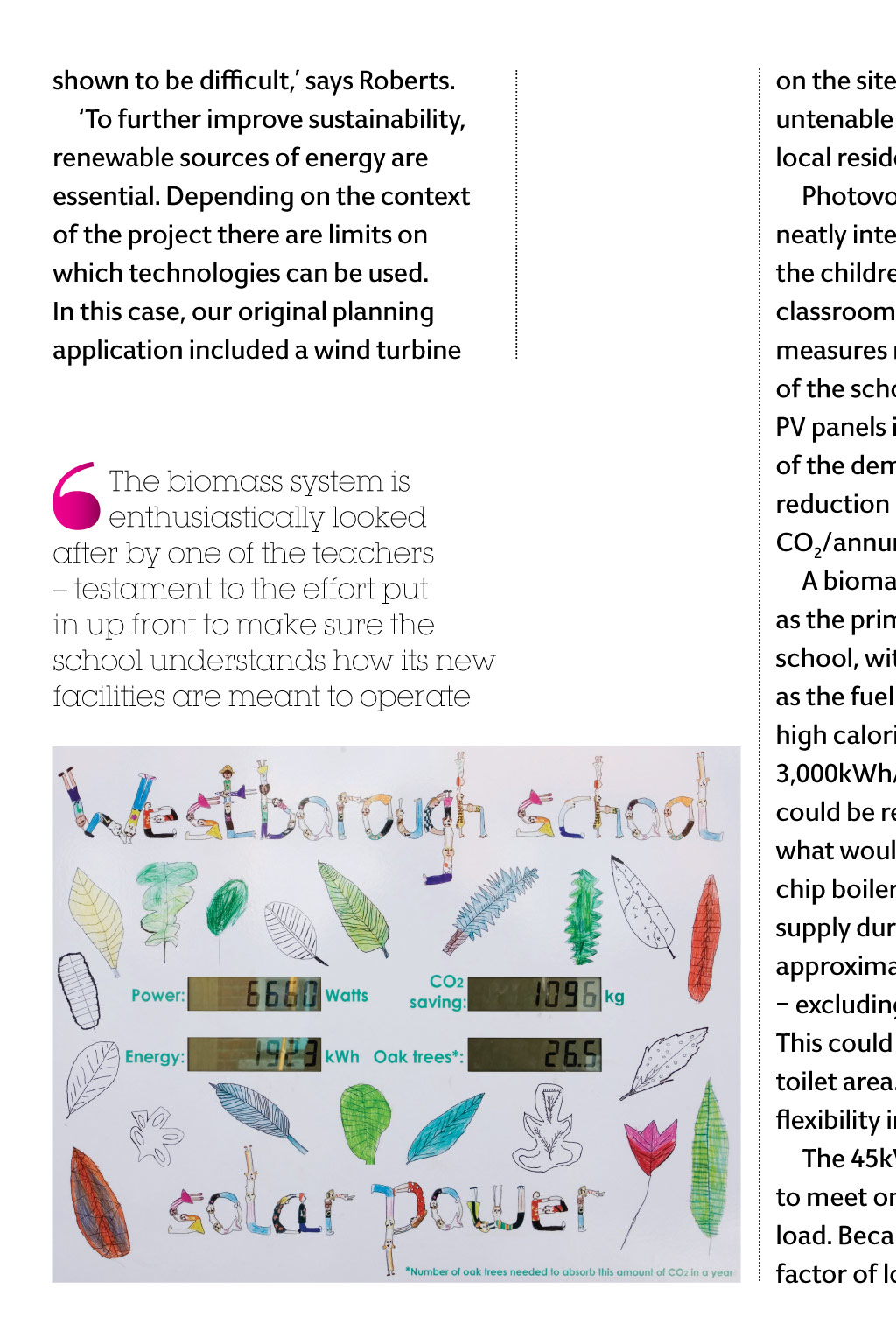

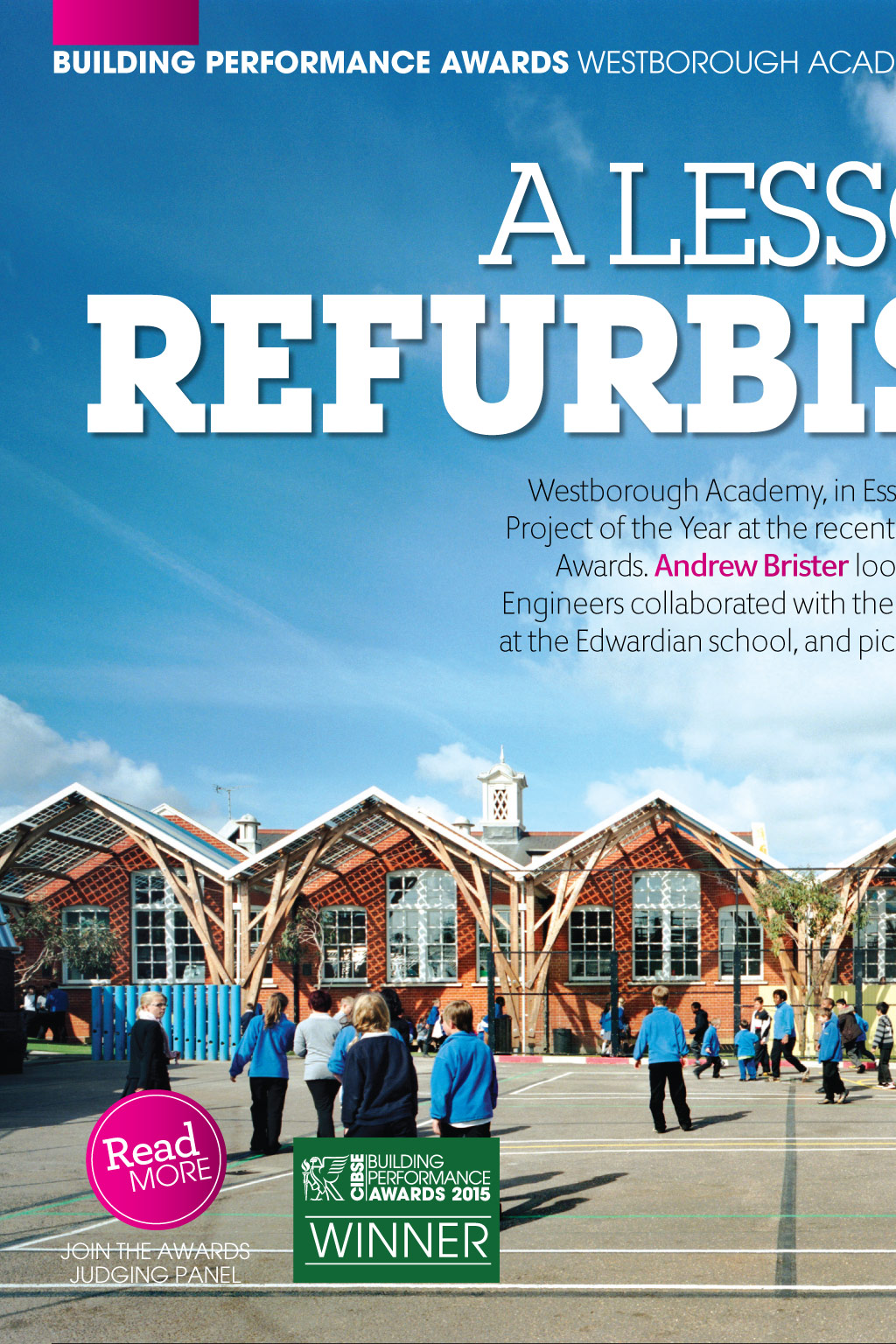

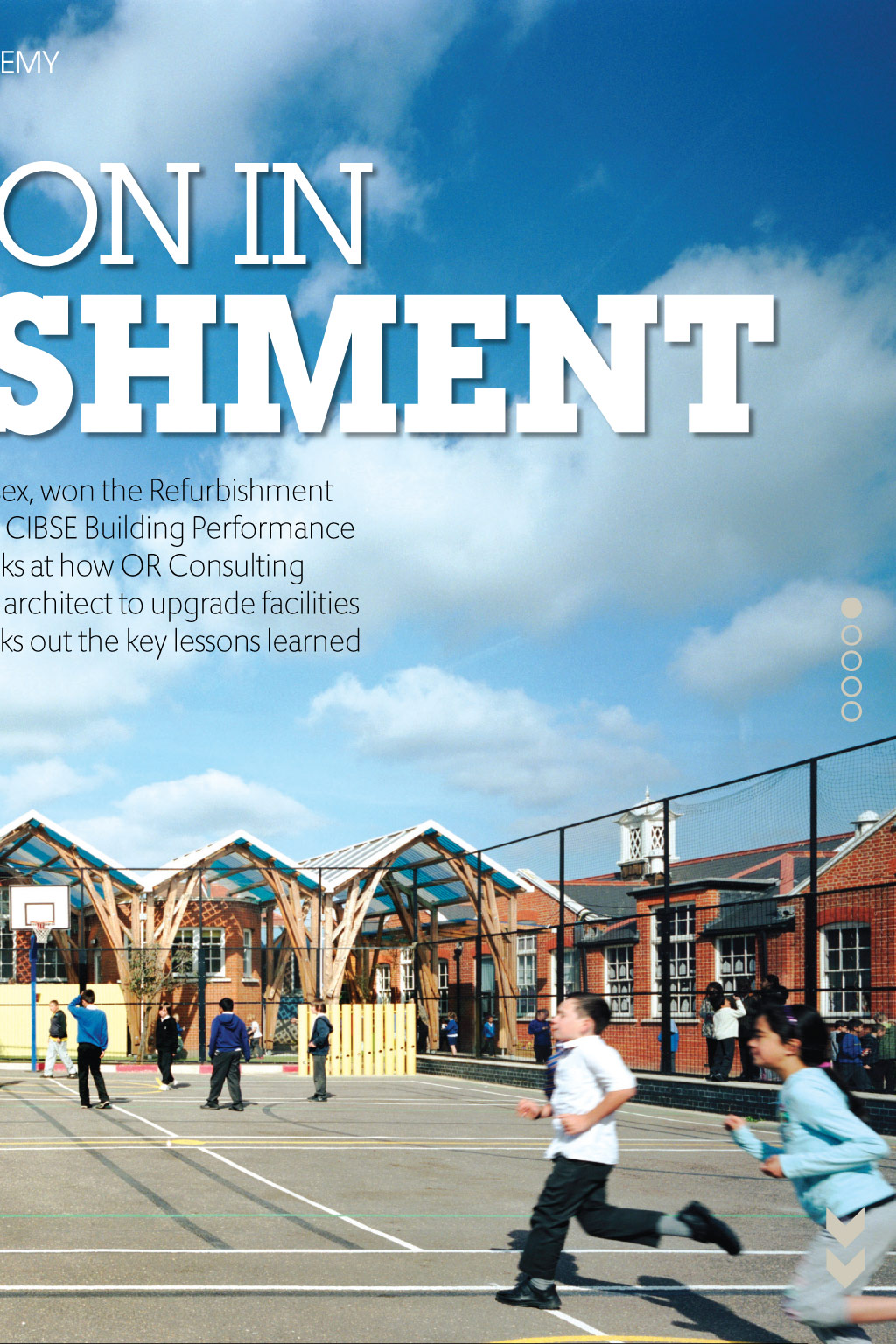

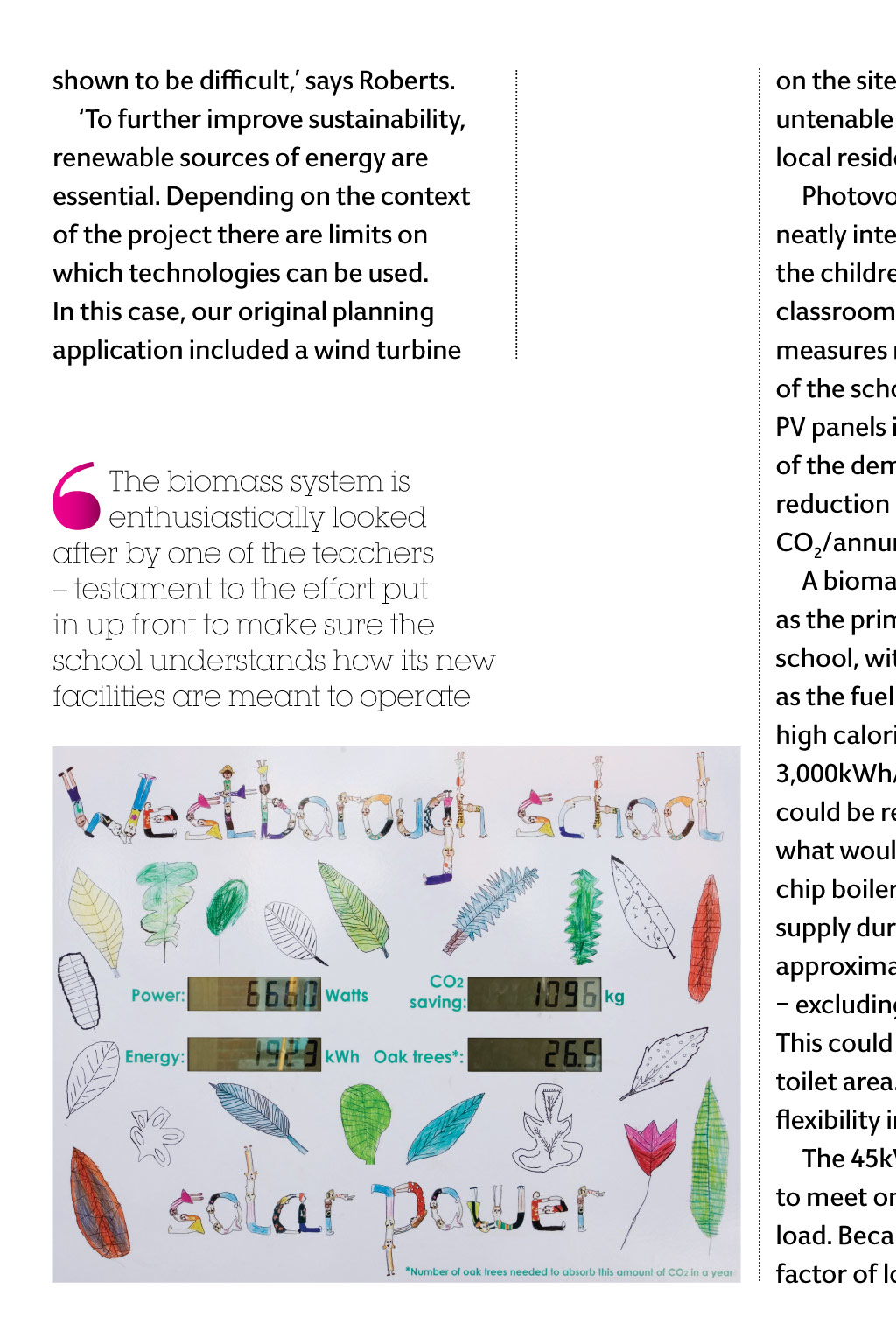

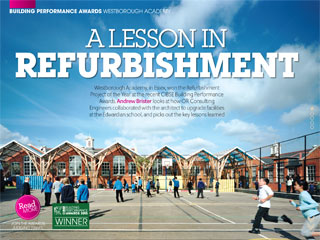

Building Performance Awards Westborough Academy A lesson in refurbIshment Westborough Academy, in Essex, won the Refurbishment Project of the Year at the recent CIBSE Building Performance Awards. Andrew Brister looks at how OR Consulting Engineers collaborated with the architect to upgrade facilities at the Edwardian school, and picks out the key lessons learned eor RmadE JoIn ThE AWArdS JudgIng PAnEL t he glory days of the Building Schools for the Future programme may be over, but there is still plenty of work in the sector for building services specialists. With capital expenditure squeezed, the emphasis in the coalitions Priority School Building Programme is now on improvement of existing facilities. A recent phased renovation of the Edwardian school buildings of Westborough Academy, in Westcliffon-Sea, Essex, offers a template for the many similar structures up and downthe country. Westborough picked up the accolade for Refurbishment Project of the Year (up to 5m) at the recent CIBSE Building Performance Awards a proud moment for building services firm OR Consulting Engineers. It was a privilege to work on the project, says managing director, Peter Roberts. With recent funding cuts to school capital programmes, refurbishment and redevelopment projects will be increasingly important methods of improving school environments with lower budgets but they also provide an excellent opportunity to add value to existing buildings and save dubbed the Zero Carbon Masterplan Refurbishment scheme a threephased approach to realising a low carbon refurbishment of the existing Edwardian structures. Whats interesting is that there has been a masterplan for the overall scheme, with more phases coming on stream as more money becomes available, says Roberts. Too often, school refurbishments are done piecemeal, with isolated packages of work and nothing to knit them together. The original masterplan goes back to 2009 and was due to be completed in April 2013 as funding was obtained over time. The Phase 1 works (1.3m) were funded by the Zero Carbon Task Force of the then Department for Children, Schools and Families (DCSF, now the Department for Education), Southend Local Education Authority (LEA) and Balfour Beatty, and were completed in March 2011. The Phase2 works (1.2m) were funded by the Academies Capital Maintenance Fund and Southend LEA, and completed in May 2012. The final stage of the masterplan project (Phase 3) was completed in April 2013. The DCSF was keen to use the school as an exemplar of how the energy required to demolish and rebuild new schools. Westborough Primary School is a three-form-entry primary school and nursery. The original Edwardian facilities have been added to and extended over the years, with new playgrounds and classroom blocks, as well as the award-winning Cardboard Building. However, the older building stock and its building services were nearing the end of their useful life, so the school looked for a refurbishment that would reflect its sustainable ethos. With a rising birth rate in the area, the improved facilities would also allow for an increased pupil intake. Enter Cottrell and Vermeulen Architects the partnership has worked with the school since 1992 on a number of infrastructure projects and OR Consulting Engineers. The result is what the team has eadE Rmor CArbon rEduCTIon STrATEgy older buildings can be refurbished with a low energy agenda, to meet the demands of contemporary education. The masterplan project provided a test bed for ways of refurbishing older school buildings in a sustainable manner and a model for future schemes, says Roberts. The project delivers information on the shown to be difficult, says Roberts. To further improve sustainability, renewable sources of energy are essential. Depending on the context of the project there are limits on which technologies can be used. In this case, our original planning application included a wind turbine The biomass system is enthusiastically looked after by one of the teachers testament to the effort put in up front to make sure the school understands how its new facilities are meant to operate free measure is considered against the lifespan of a renovated building which has already served its community for a century it is a more persuasive proposition. The DSCF continued to support the adoption of these technologies regardless of the financial performance, because it wanted to understand: How the technologies performed inpractice The educational value of children engaging with the operation and performance of these technologies The maintenance burden over the life-cycle of the building The robustness of the adoption of some technologies in a primary school environment. The fact that the refurbishment was split into phases meant that the team were able to learn from the initial phase and improve as the project progressed. The later phases were much quicker as we learned about the necessary detailing of the thermal insulation, dry lining and the best routing for services in an Edwardian building, says Roberts. The collaborative nature of the project has also reaped other rewards: the team on the site, which proved to be untenable following opposition from local residents. Photovoltaic panels have been neatly integrated on a walkway that the children use to travel between classrooms. The Lean and Mean measures reduced the electrical load of the school by 30%. The 400m2 of PV panels installed can supply 70% of the demand, leading to a carbon reduction estimated at 17,000kg CO2/annum. A biomass boiler has been included as the primary heat source for the school, with wood pellets chosen as the fuel. Wood pellets have a high calorific value approximately 3,000kWh/m3 so the store size could be reduced compared with what would be needed for a woodchip boiler. Based on a two-week supply during peak heating season, approximately 3m3 of storage space excluding access area is required. This could be accommodated in an old toilet area. Gas boiler backup allows flexibility in supply. The 45kW biomass boiler is sized to meet one-third of the peak load. Because of the low carbon factor of localised biomass boiler effectiveness of carbonreduction strategies that can be applied to typical existing primary school buildings. Phase 1 of the masterplan resulted in the introduction of renewable technologies (biomass and solar photovoltaics) as part of a Lean, Mean and Green strategy (see box); the upgrade of the fabric in certain blocks; and the creation of a multi-use hall that could be made into one large space or subdivided into seven smaller areas using folding, acoustic partitions. As further blocks were refurbished in Phases 2 and 3, the extension of the low carbon heating system increased the base load of the biomass boiler and optimised running hours. In addition, water-management strategies such as rainwater recycling and waterefficient sanitary fittings were used to reduce water consumption. The issue of accommodating renewables in a dense, urban area, with housing on all sides, needed careful consideration. Reducing carbon emissions to zero through refurbishment of an existing building, based solely on improvements to building fabric and services, has been systems (0.025kgCO2/kWh), the biomass system is estimated to save two-thirds of the annual heating carbon emissions, which equates to approximately 17,000kgCO2/annum. The biomass system is enthusiastically looked after by one of the teachers testament to the effort put in up front to make sure the school understands how its new facilities are meant to operate (see panel, Soft landings). Performance feedback After completion of Phase 1, Buro Happolds Alternative Technology and Sustainability Unit was brought in to assess the buildings performance, and reported a 30% reduction in carbon emissions. In terms of energy consumption, the refurbished areas of the Edwardian school perform 17% better thanatypical primary school, based on ECON 73 benchmarks. Critics will point to long payback periods in excess of 30 years for the biomass boiler and solar PV. Generally, the paybacks are uneconomic, admits Roberts. The fabric improvement measures have paybacks in the region of 23 years. In a financial sense, this improvement is not attractive in isolation, but when this maintenance- are working together on other schools projects, as well as a low carbon Hindu temple in Hertfordshire. Westborough promises to deliver much-needed feedback on what works and what doesnt as the nation looks to revamp its ageing building stock. Lets hope designers do their homework and follow some of the lessons learned from this awardwinning refurbishment. cJ Soft landings The design team carried out a series of presentations to the client, teaching staff, local authority and DCSF at key stages of the project. The aim was to inform and define the developing brief, and to begin educating users on how to operate and occupy their new building efficiently. Towards the end of the project, a soft-landing process was employed by the design team and contractor to communicate the key principles of the design, and the key environmental strategies required for efficient operation. Dedicated training sessions attended by the design team, contractors and staff were carried out for the biomass heating installation and controls. The team also offered support to the school post-completion, to ensure a smooth transition into occupation for the client. This process has paid real dividends and the school has taken pride in their new buildings, says Peter Roberts, of OR Consulting Engineers. As well as teacher involvement in running the biomass installation, data from the submetering and PV display panel have been used in the teaching of the maths curriculum. LEAn, mEAn And grEEn JoIn ThE JudgIng PAnEL The Awards judging panel consists of individuals whose combined skills and knowledge span all the elements that impact upon the performance of a building. If you are interested in getting involved then wed like to hear from you. Applications close 5 May 2015. For more information visit www.cibse.org/judging WINNER The carbon-reduction strategy at Westborough is based on the adoption of Lean, Mean and Green measures. The Lean strategy reduced energy demands, improving the existing building fabric by internally lining wallsand roofs with thermal and acoustic insulation, refurbishing windows and improving building air-tightness. The Mean strategy produced savings through the introduction of: energy-efficient lighting; lighting controls; heat-recovery ventilation; power-factor correction; voltage correction; sub-metering; condensing boilers to supply supplementary heating to the biomass system; and new controls for the building services. The Green strategy introduced renewable energy systems to the project, namely biomass heating and photovoltaic panels.