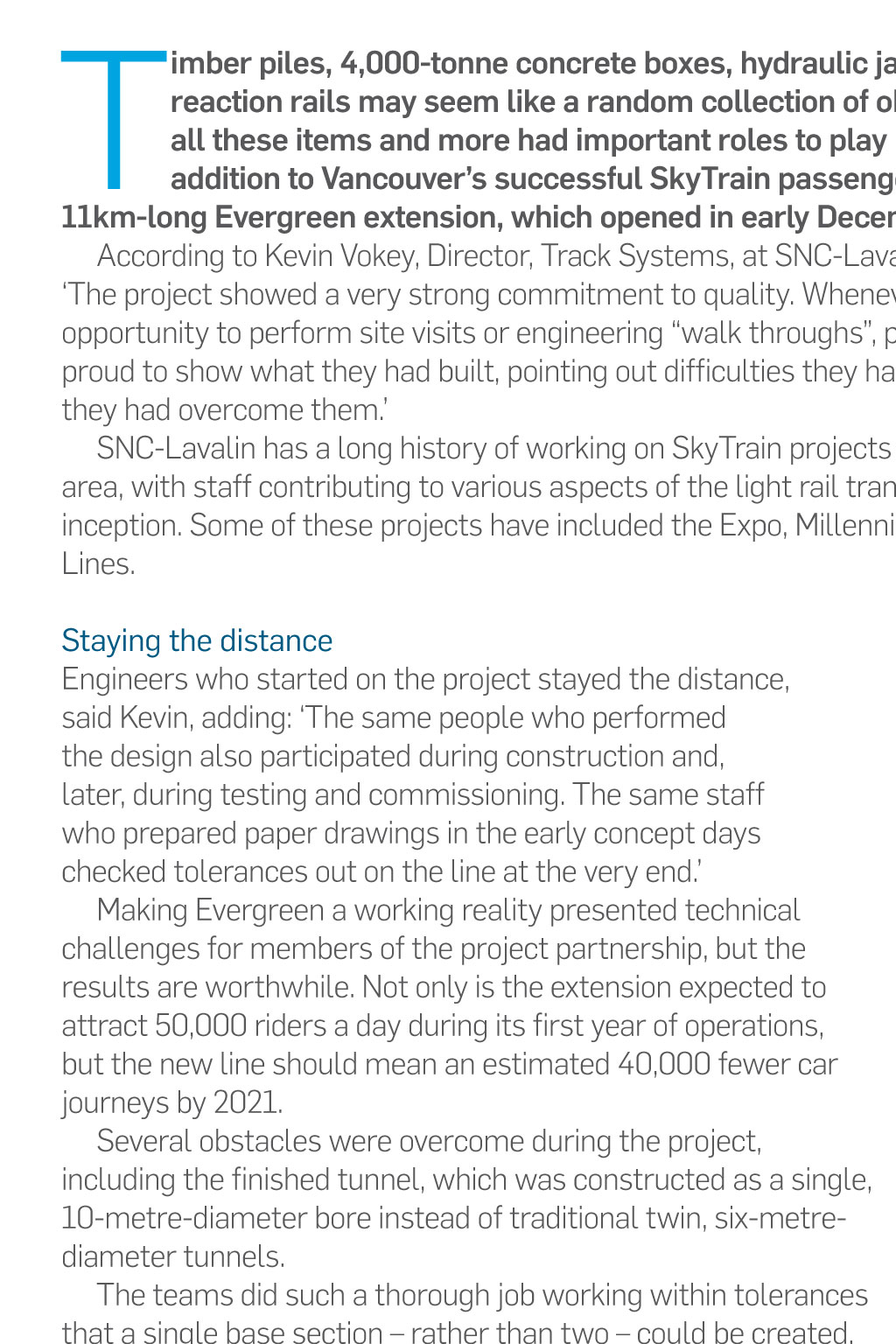

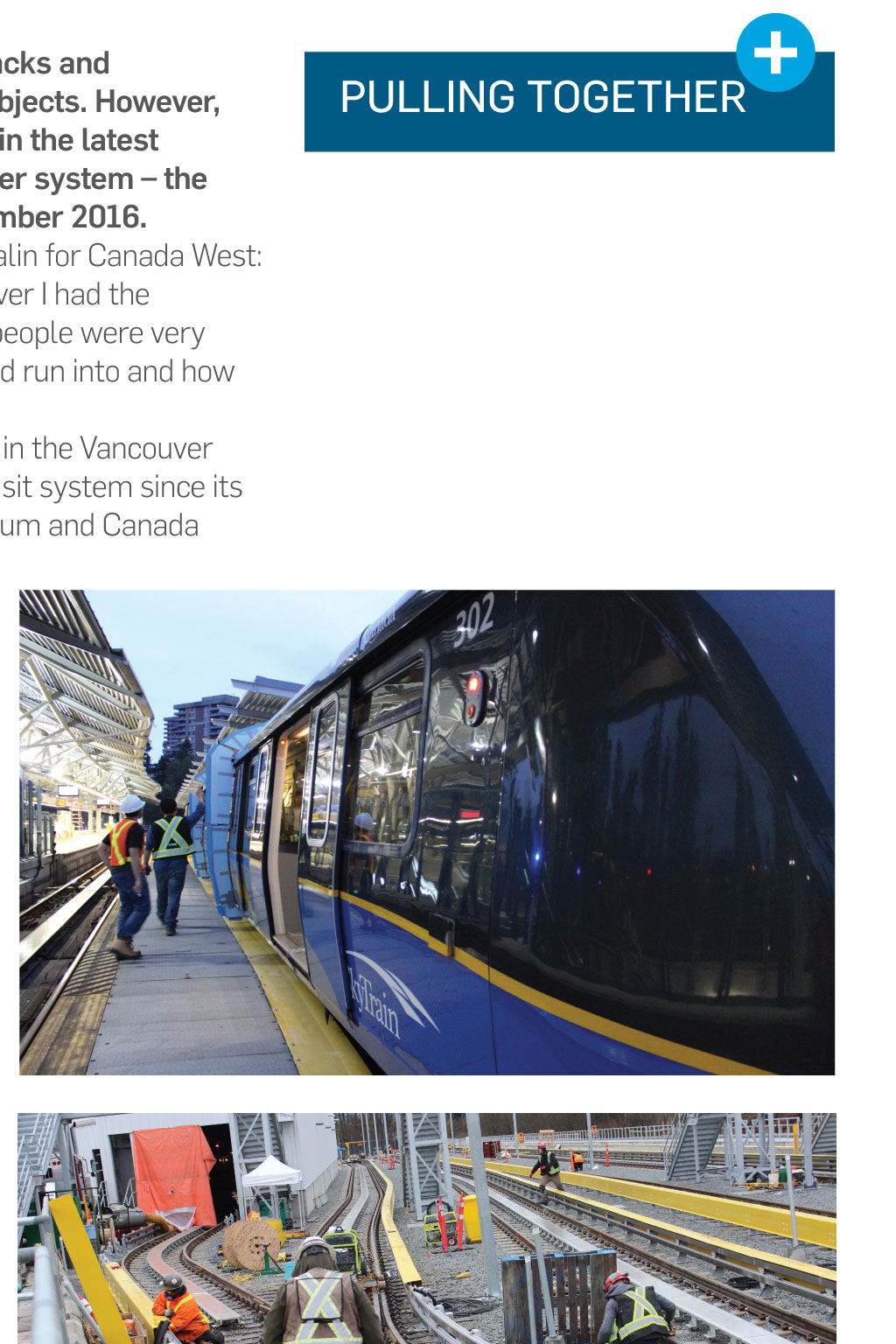

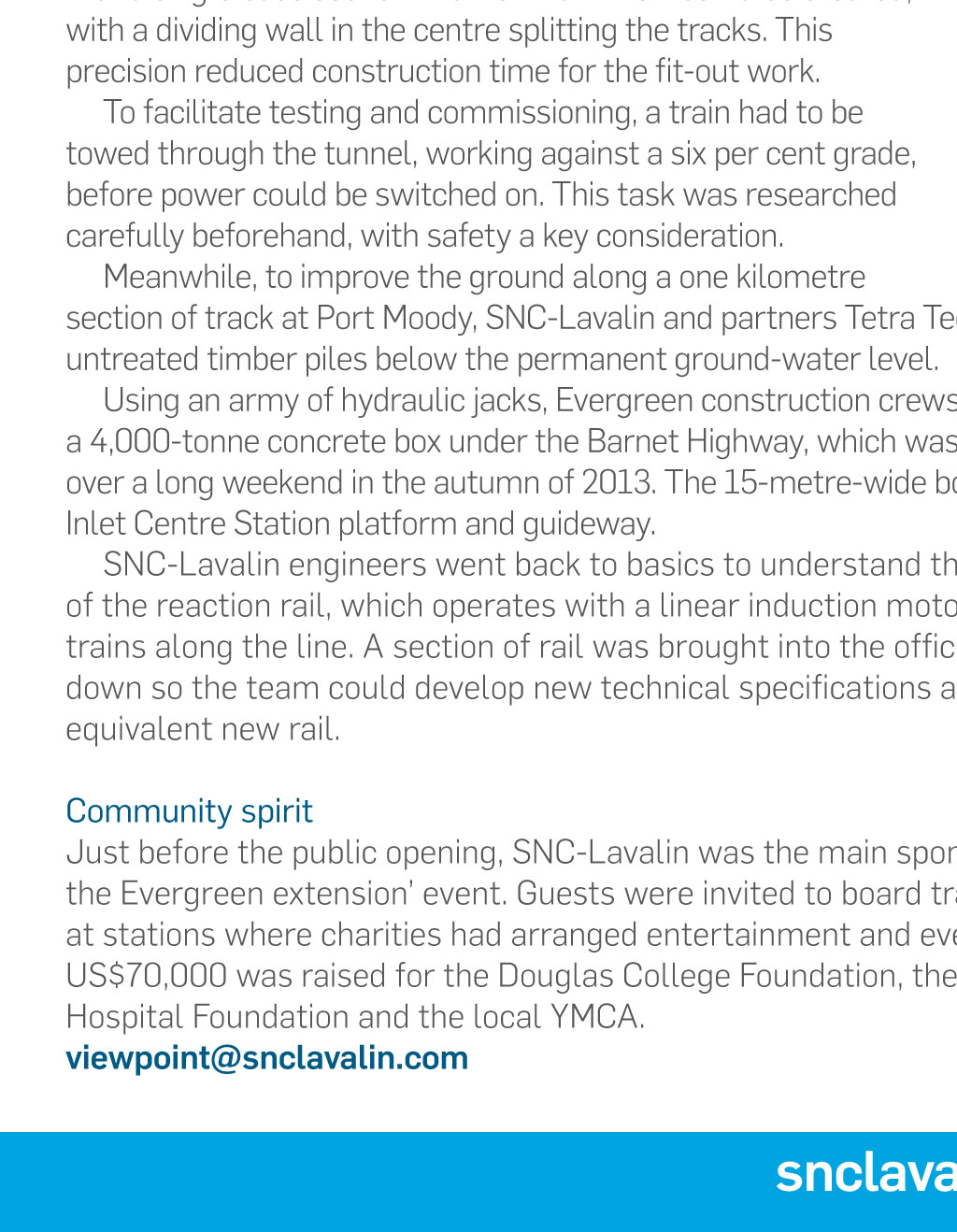

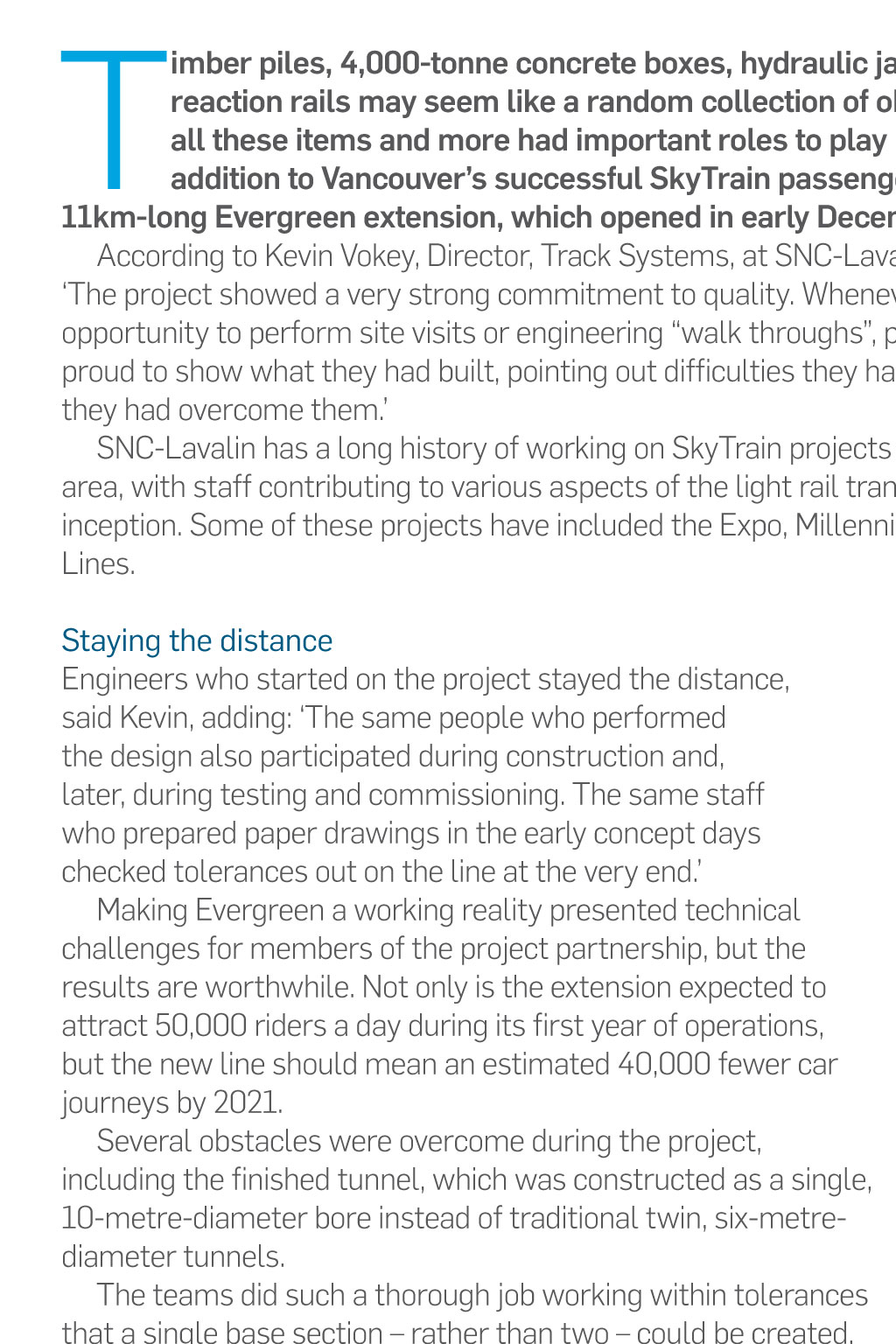

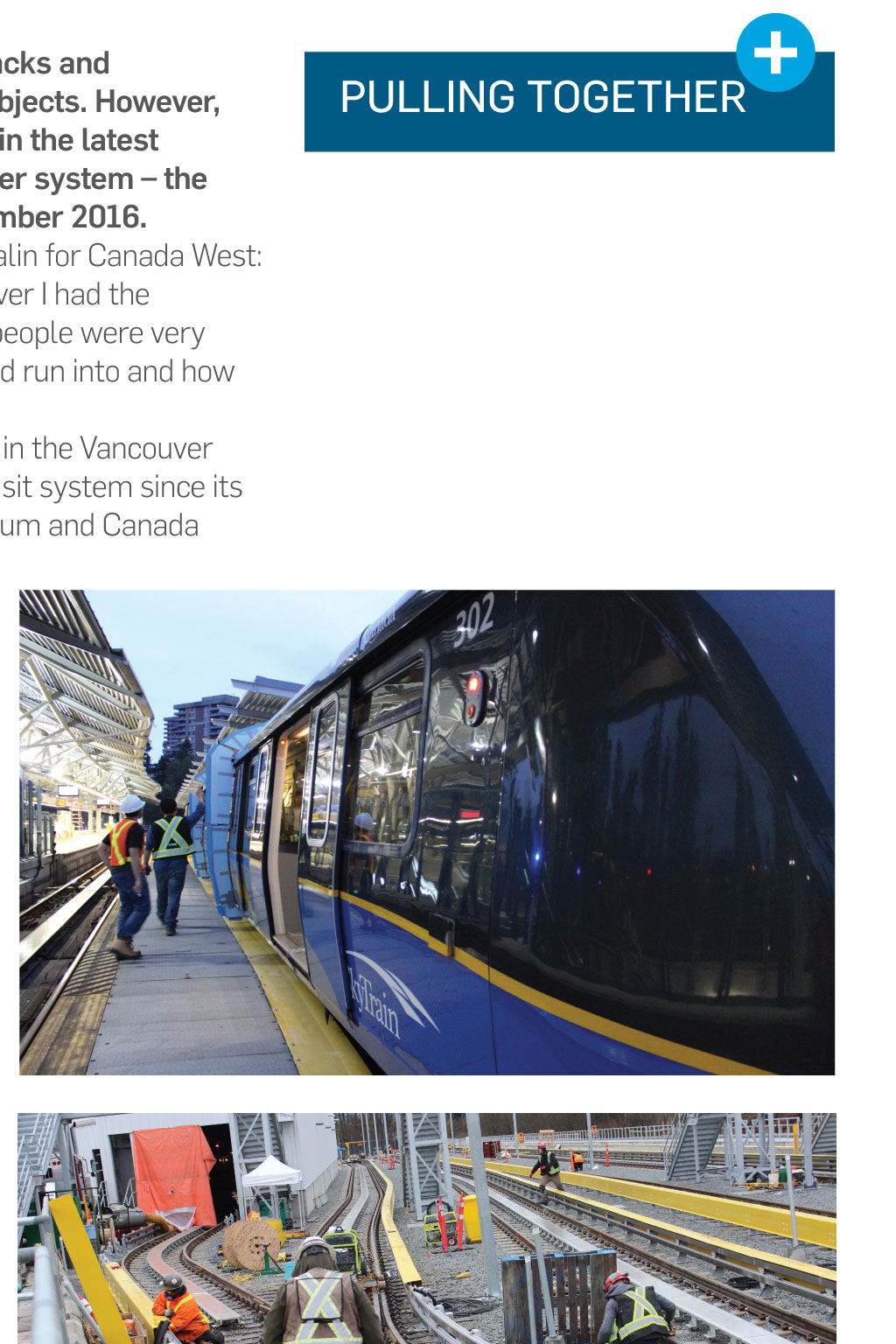

Projects Evergreen Line Tunnelling their way to success The latest piece of Vancouvers SkyTrain light rail transit system is now in place, with passenger services on the new line having started last December. Before this could become a reality, SNC-Lavalin and its project partners had to put their problem-solving abilities to the test. Viewpoint found out more WoRDS A NDREW BENNETT P hoToS S COTT ROBERTS T imber piles, 4,000-tonne concrete boxes, hydraulic jacks and reaction rails may seem like a random collection of objects. however, all these items and more had important roles to playin the latest addition to Vancouvers successful SkyTrain passenger system the 11km-long Evergreen extension, which opened in early December 2016. According to Kevin Vokey, Director, Track Systems, at SNC-Lavalin for Canada West: The project showed a very strong commitment to quality. Whenever I had the opportunity to perform site visits or engineering walk throughs, people were very proud to show what they had built, pointing out difficulties they had run into and how they had overcome them. SNC-Lavalin has a long history of working on SkyTrain projects in the Vancouver area, with staff contributing to various aspects of the light rail transit system since its inception. Some of these projects have included the Expo, Millennium and Canada Lines. Staying the distance Engineers who started on the project stayed the distance, said Kevin, adding: The same people who performed the design also participated during construction and, later, during testing and commissioning. The same staff who prepared paper drawings in the early concept days checked tolerances out on the line at the very end. Making Evergreen a working reality presented technical challenges for members of the project partnership, but the results are worthwhile. Not only is the extension expected to attract 50,000 riders a day during its first year of operations, butthe new line should mean an estimated 40,000 fewer car journeys by 2021. Several obstacles were overcome during the project, including the finished tunnel, which was constructed as a single, 10-metre-diameter bore instead of traditional twin, six-metrediameter tunnels. The teams did such a thorough job working within tolerances that a single base section rather than two could be created, with a dividing wall in the centre splitting the tracks. This precision reduced construction time for the fit-out work. To facilitate testing and commissioning, a train had to be towed through the tunnel, working against a six per cent grade, before power could be switched on. This task was researched carefully beforehand, with safety a key consideration. Meanwhile, to improve the ground along a one kilometre section of track at Port Moody, SNC-Lavalin and partners Tetra Tech installed untreated timber piles below the permanent ground-water level. Using an army of hydraulic jacks, Evergreen construction crews also pushed a4,000-tonne concrete box under the BarnetHighway, which was temporarily closed over a long weekend in the autumn of 2013. The 15-metre-wide box forms part of the Inlet Centre Station platform and guideway. SNC-Lavalin engineers went back to basicsto understand the workings of thereaction rail, which operates with a linearinduction motor to pull trainsalongtheline. A section of rail was broughtinto the office and stripped down so the team could develop new technical specifications and purchase an equivalent new rail. Community spirit Just before the public opening, SNC-Lavalin was the main sponsor of a ride the Evergreen extension event. Guests were invited to board trains and get off at stations where charities had arranged entertainment and events. Around US$70,000 was raised for the Douglas College Foundation, the Eagle Ridge Hospital Foundation and the local YMCA. viewpoint@snclavalin.com snclavalin.com pulling together pulling together Joining SNC-Lavalin on Evergreen were joint venture partners and key subcontractors: Graham Building Services; PCLConstruction Westcoast; Rizzani de Eccher; SELI; International Bridge Technologies; McMillen Jacobs Associates; MMM Group Canada (WSP People were very proud to show what they had built, pointing out difficulties they had run into and how they had overcome them Kevin Vokey Director, Track Systems