Metrology case study

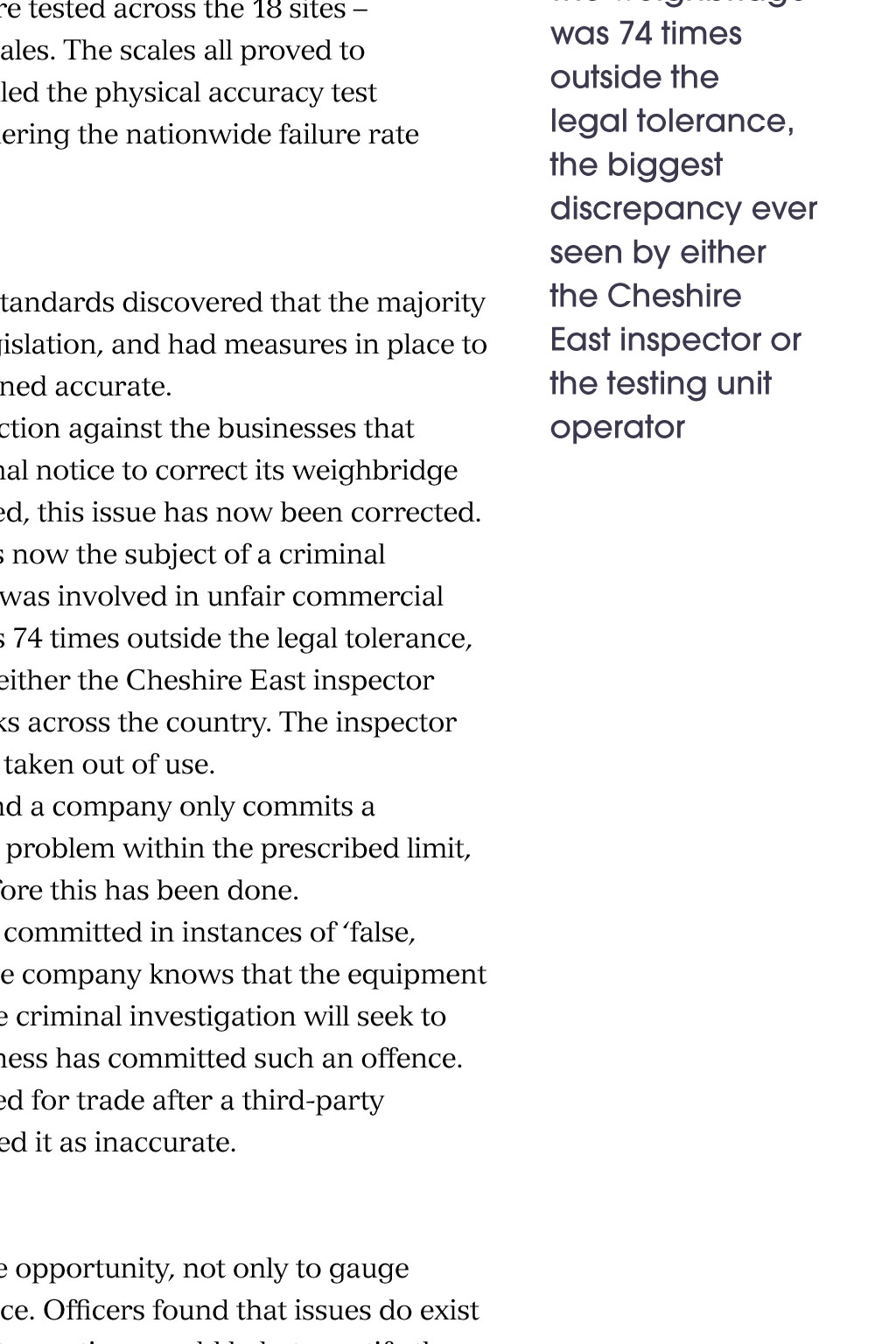

, "22":"Metrology case study In this feature testing accuracy fair trading A project conducted in Cheshire East shows that a fair trading environment requires active regulation of weights and measures the Following on from the project, officers identified future steps to ensure this area of commerce is well regulated, including: G Visits to similar premises that were not included this time around G Criminal investigation of a non-compliant business G Sharing data and intelligence with other concerned organisations, such as the National Measurement Office G Advisory mailshots to relevant businesses, reporting the findings of the project (subject to confidentiality) G Exploring options for future joint working with environmental health and/or the British Transport Police G Running a similar operation to focus on bulk fuel measurement in the borough The Weights & Measures Act 1985 establishes the legal units of measurement in the UK. It removed many of the traditional imperial units and replaced them with metric measurements, although some were retained, such as the pint measure of beer. It also sets out rules for inspection and denotes when an individual has committed an offence: for example, by unfairly weighing and measuring. The Weighing Equipment (Non-automatic Weighing Machines) Regulations 2000 apply to any weighing equipment used for trade. These regulations establish the materials, principles of construction and marking required of such machines, and how they can be used. The regulations also make prescriptions about testing and acceptable margins of error. T he most basic principle of a fair trading environment is that everyone should get what they pay for, and the key to this is ensuring that businesses are using accurate weighing and measuring equipment. Trading standards officers from Cheshire East conducted an operation to find out just how accurate such equipment is, and may have found an instance of fraud into the bargain. A fair market? Every year, private businesses in the Cheshire East unitary authority area use large-capacity weighing equipment in transactions collectively worth millions of pounds. So officers considered it essential to perform tests to find out whether a fair marketplace existed. What equipment was being used and how accurate was it? How competent were businesses in using it? With a new regulatory regime for scrap yards, how compliant were these businesses? Was there any evidence of fraud? Officers wanted answers to all of these questions. Heavy loads Large-capacity weighing equipment takes two forms. Weighbridges are large scales, commonly with a capacity of up to 50 tonnes. Vehicles are weighed before and after loading. After the second weighing, the driver will be issued with an official weight ticket with the calculated net weight of the goods this forms the loads transactional value. Commodities such as scrap, food ingredients, milk, environmental waste and chemical products are all sold by weight, and the quantities are often determined using this method. Platform scales are smaller, dealing with weights of up to five tonnes, and are usually used for loose goods, such as coal or building products, without weighing a vehicle. The challenges Trading standards officers in Cheshire East have calibrating, weighing and measuring testing equipment for inspectors to use, both on programmed and reactive inspections. However, large-capacity weighing equipment is a special case. Due to local government reforms, the former county of Cheshire was divided into eastern and western unitary authorities in 2009. However, during the split, Cheshire West and Chester Council kept hold of the weights and measures calibration facility and the testing units used for large-capacity weighing equipment. An agreement allowing Cheshire East to continue using the facilities expired in April 2013 meaning that the equipment had to be hired back for five days, at a daily cost of 430, plus excess mileage. It was hoped that Cheshire East officials could work with police officers to deliver the project; Operation Tornado, a crackdown on metal thieves administered by the British Transport Police, was identified as a possible source of support. Unfortunately, reduced funding in this area made collaboration impossible at that time. So officers opted to press on alone. One of the sites checked in Cheshire East The process Officers first identified all relevant businesses, then sent letters asking them to provide information on their weighing equipment. Of the 50 businesses written to by trading standards, only 26 replied, leading officers to conclude that these messages should be sent using recorded or special delivery in future, so that the recipient must sign for the letter. The replies were then reviewed and assessed. Some of the private premises that operated weighbridges and platform scales had not been visited by inspectors for many years, so a site visit was necessary to find out whether these businesses were still open and using the equipment. Based on the responses, the date of the last visit and the location of the sites, a route was drawn up for the weighbridge test unit to visit the premises. As there were too many sites to visit in five days, pre-visits were undertaken to make sure that everything would run smoothly. Inspectors carried out some onsite audits without the testing unit where it was deemed appropriate they checked the physical state of the equipment, asked about its use and the training received by staff, determined calibration frequency and also found out about service contracts held with third parties. After this, the testing unit began its rounds, eventually inspecting 18sites across the borough, including farms, scrap yards, railway sidings and sand quarries. Routine introductions on site, plus explanations of whatthe visit would entail, then took place. At each stop, inspectors checked the business processes, licenses, records and equipment. They also engaged with staff members to determine their expertise. Meanwhile, the testing unit operator performed repeated manual checks on the weighbridge with a range of loads. All of the businesses tested were cooperative. In total, 23 pieces of equipment were tested across the 18 sites 19weighbridges and four platform scales. The scales all proved to beaccurate, but two weighbridges failed the physical accuracy test (11percent) a positive result, considering the nationwide failure rate is20per cent. Criminal offence As a result of this operation, trading standards discovered that the majority of businesses were compliant with legislation, and had measures in place to make sure that their equipment remained accurate. Cheshire East is now able to take action against the businesses that failed the tests. One was issued a formal notice to correct its weighbridge and, according to the business involved, this issue has now been corrected. The other organisation, however, is now the subject of a criminal investigation to determine whether it was involved in unfair commercial practices. There, the weighbridge was 74 times outside the legal tolerance, the biggest discrepancy ever seen by either the Cheshire East inspector or the testing unit operator, who works across the country. The inspector ordered that it should be immediately taken out of use. Usually, a formal notice is issued and a company only commits a criminal offence if it fails to rectify the problem within the prescribed limit, or continues to use the equipment before this has been done. However, a criminal offence is also committed in instances of false, unjust or fraudulent use that is, if the company knows that the equipment is not accurate but uses it anyway. The criminal investigation will seek to establish whether this particular business has committed such an offence. It seems that the weighbridge was used for trade after a third-party inspection, which had already identified it as inaccurate. The weighbridge was 74 times outside the legal tolerance, the biggest discrepancy ever seen by either the Cheshire East inspector or the testing unit operator Valuable operation This operation proved to be a valuable opportunity, not only to gauge compliance, but also to gain intelligence. Officers found that issues do exist in the marketplace and that further interventions could help to rectify them, highlighting the importance of this regulatory activity. To help with possible future operations, officers now have up-to-date information about which premises are operating this kind of equipment, along with details of closures and changes of ownership. The visits were logged on the Memex intelligence management system so that compliance levels are there for local government officials to examine. Officers also gained experience and working knowledge of this area, which may prove useful in future. Even better, the businesses visited by officers now understand that trading standards is vigilant in the cause of protecting consumers and is there to ensure a fair trading environment for businesses. RECTIFYING THE PROBLEM Credits Published Rob Coston is a reporter for TS Today. Tuesday 24 March, 2015 Images: Altana8 / Shutterstock RELEVANT LEGISL ATION To share this page, click on in the toolbar "