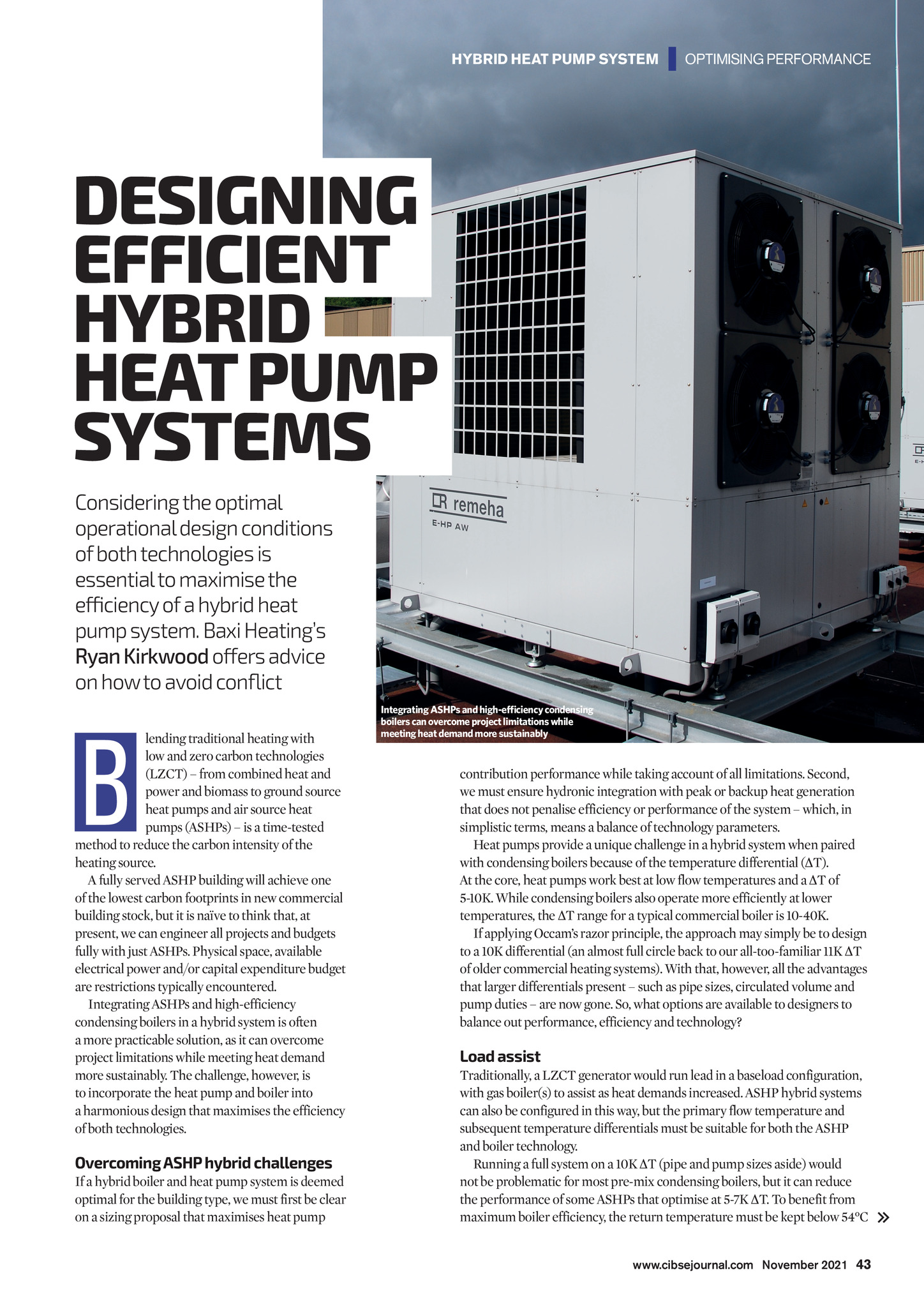

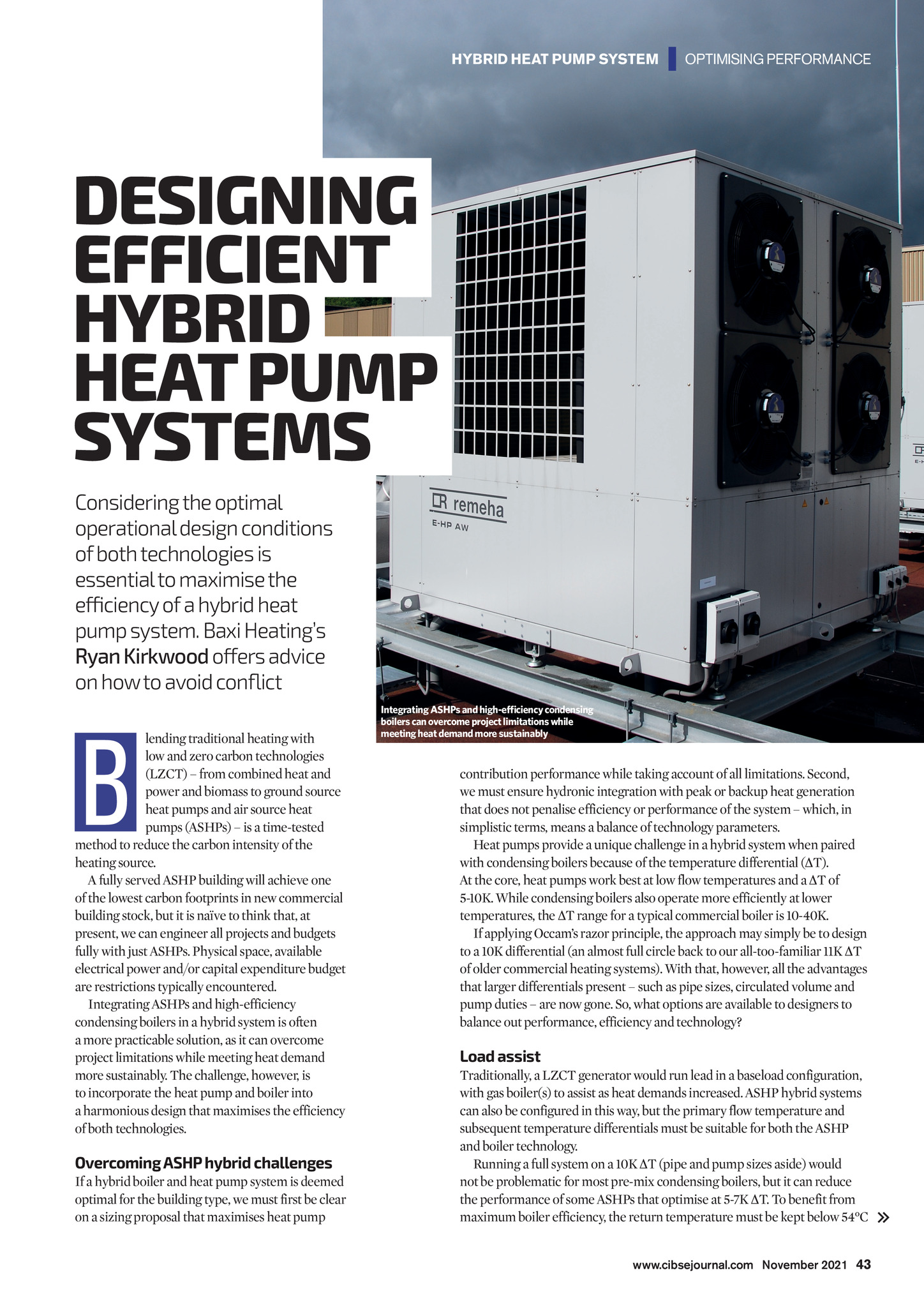

HYBRID HEAT PUMP SYSTEM | OPTIMISING PERFORMANCE DESIGNING EFFICIENT HYBRID HEAT PUMP SYSTEMS Considering the optimal operational design conditions of both technologies is essential to maximise the efficiency of a hybrid heat pump system. Baxi Heatings Ryan Kirkwood offers advice on how to avoid conflict B lending traditional heating with low and zero carbon technologies (LZCT) from combined heat and power and biomass to ground source heat pumps and air source heat pumps (ASHPs) is a time-tested method to reduce the carbon intensity of the heating source. A fully served ASHP building will achieve one of the lowest carbon footprints in new commercial building stock, but it is nave to think that, at present, we can engineer all projects and budgets fully with just ASHPs. Physical space, available electrical power and/or capital expenditure budget are restrictions typically encountered. Integrating ASHPs and high-efficiency condensing boilers in a hybrid system is often a more practicable solution, as it can overcome project limitations while meeting heat demand more sustainably. The challenge, however, is to incorporate the heat pump and boiler into a harmonious design that maximises the efficiency of both technologies. Overcoming ASHP hybrid challenges If a hybrid boiler and heat pump system is deemed optimal for the building type, we must first be clear on a sizing proposal that maximises heat pump contribution performance while taking account of all limitations. Second, we must ensure hydronic integration with peak or backup heat generation that does not penalise efficiency or performance of the system which, in simplistic terms, means a balance of technology parameters. Heat pumps provide a unique challenge in a hybrid system when paired with condensing boilers because of the temperature differential ( T). At the core, heat pumps work best at low flow temperatures and a T of 5-10K. While condensing boilers also operate more efficiently at lower temperatures, the T range for a typical commercial boiler is 10-40K. If applying Occams razor principle, the approach may simply be to design to a 10K differential (an almost full circle back to our all-too-familiar 11K T of older commercial heating systems). With that, however, all the advantages that larger differentials present such as pipe sizes, circulated volume and pump duties are now gone. So, what options are available to designers to balance out performance, efficiency and technology? Load assist Traditionally, a LZCT generator would run lead in a baseload configuration, with gas boiler(s) to assist as heat demands increased. ASHP hybrid systems can also be configured in this way, but the primary flow temperature and subsequent temperature differentials must be suitable for both the ASHP and boiler technology. Running a full system on a 10K T (pipe and pump sizes aside) would not be problematic for most pre-mix condensing boilers, but it can reduce the performance of some ASHPs that optimise at 5-7K T. To benefit from maximum boiler efficiency, the return temperature must be kept below 54C www.cibsejournal.com November 2021 43 CIBSE Nov21 pp43-44, 46 Hybrid heat pumps.indd 43 22/10/2021 18:21