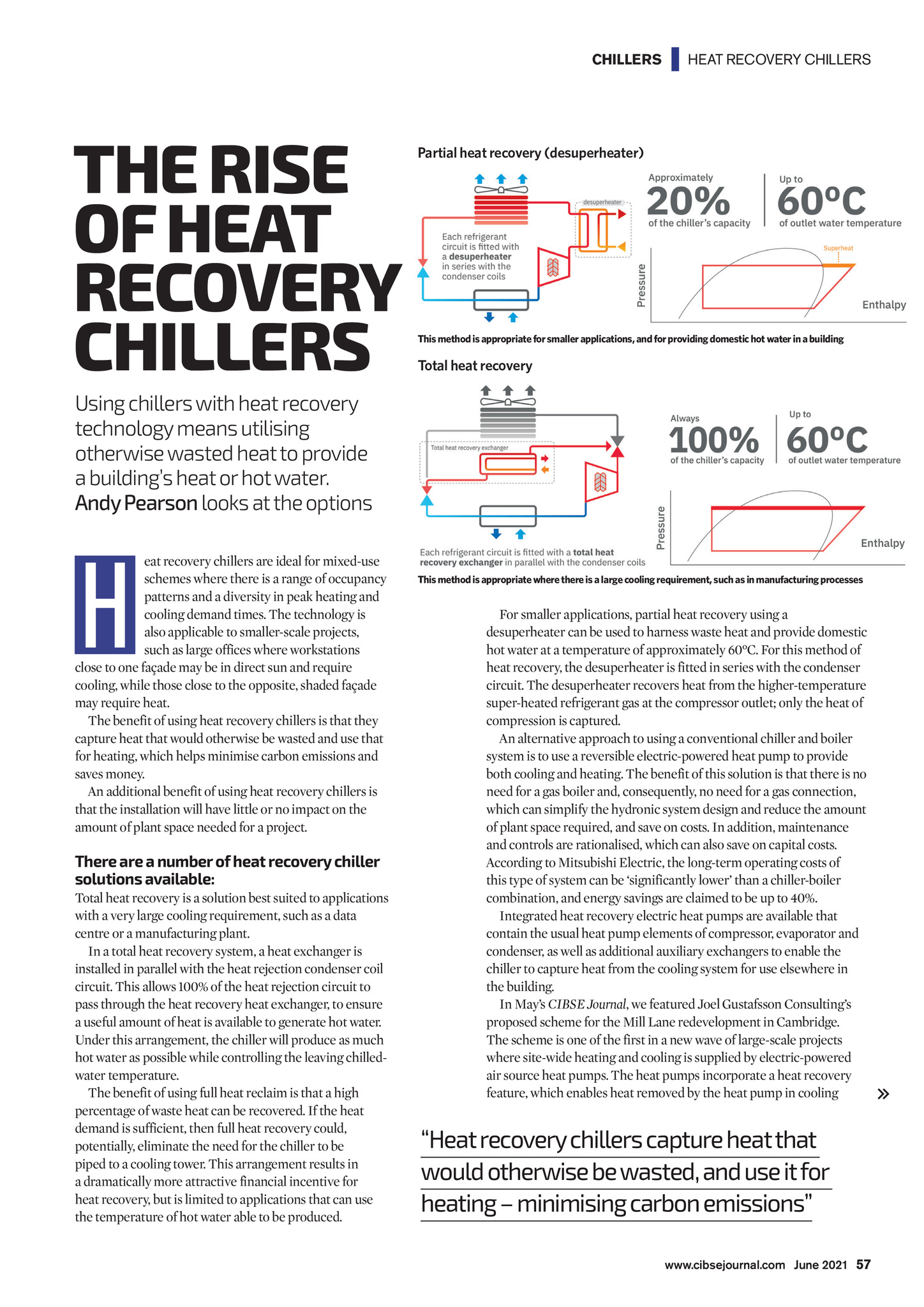

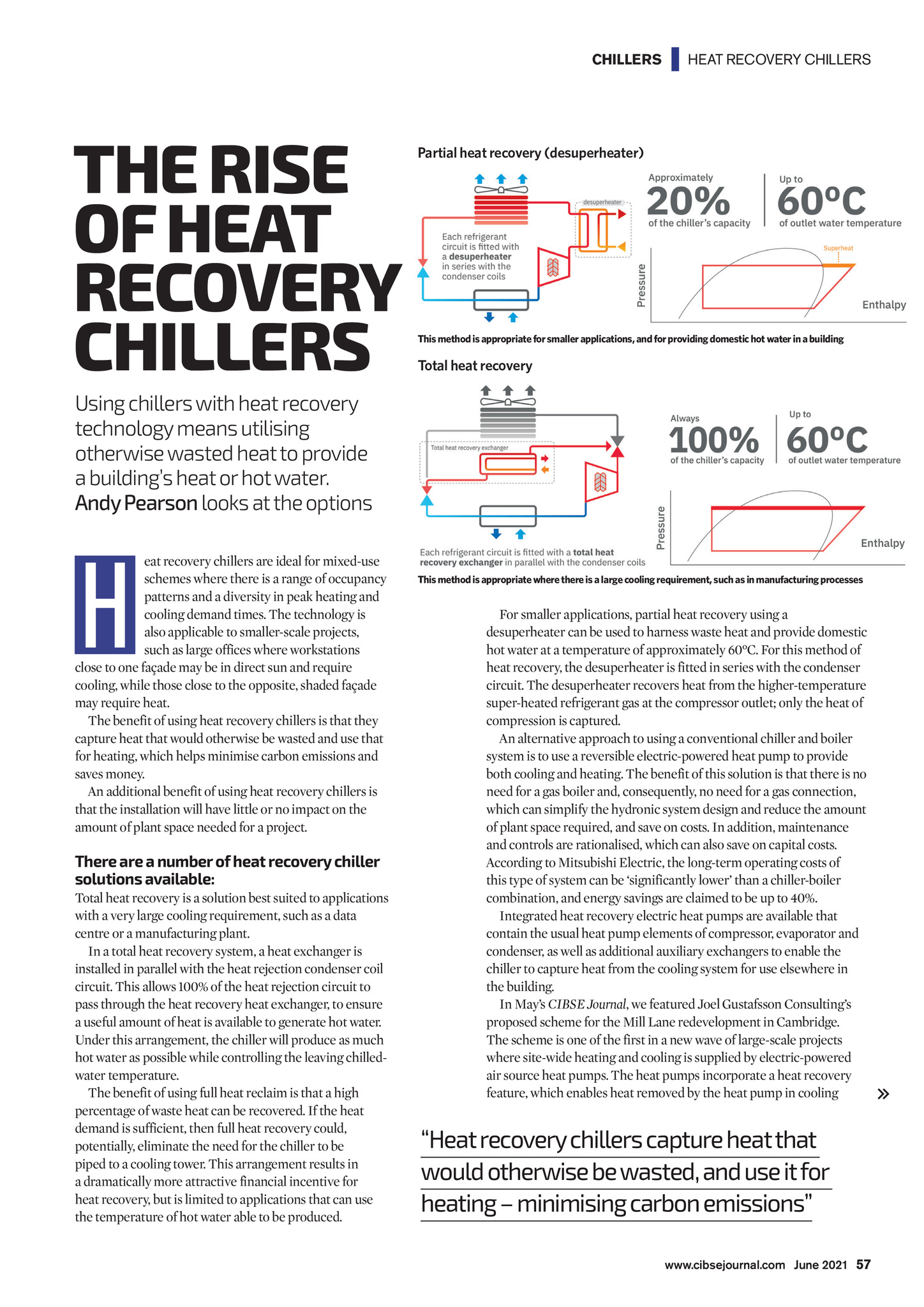

CHILLERS THE RISE OF HEAT RECOVERY CHILLERS | HEAT RECOVERY CHILLERS Partial heat recovery (desuperheater) This method is appropriate for smaller applications, and for providing domestic hot water in a building Total heat recovery Using chillers with heat recovery technology means utilising otherwise wasted heat to provide a buildings heat or hot water. Andy Pearson looks at the options H eat recovery chillers are ideal for mixed-use schemes where there is a range of occupancy patterns and a diversity in peak heating and cooling demand times. The technology is also applicable to smaller-scale projects, such as large offices where workstations close to one faade may be in direct sun and require cooling, while those close to the opposite, shaded faade may require heat. The benefit of using heat recovery chillers is that they capture heat that would otherwise be wasted and use that for heating, which helps minimise carbon emissions and saves money. An additional benefit of using heat recovery chillers is that the installation will have little or no impact on the amount of plant space needed for a project. There are a number of heat recovery chiller solutions available: Total heat recovery is a solution best suited to applications with a very large cooling requirement, such as a data centre or a manufacturing plant. In a total heat recovery system, a heat exchanger is installed in parallel with the heat rejection condenser coil circuit. This allows 100% of the heat rejection circuit to pass through the heat recovery heat exchanger, to ensure a useful amount of heat is available to generate hot water. Under this arrangement, the chiller will produce as much hot water as possible while controlling the leaving chilledwater temperature. The benefit of using full heat reclaim is that a high percentage of waste heat can be recovered. If the heat demand is sufficient, then full heat recovery could, potentially, eliminate the need for the chiller to be piped to a cooling tower. This arrangement results in a dramatically more attractive financial incentive for heat recovery, but is limited to applications that can use the temperature of hot water able to be produced. This method is appropriate where there is a large cooling requirement, such as in manufacturing processes For smaller applications, partial heat recovery using a desuperheater can be used to harness waste heat and provide domestic hot water at a temperature of approximately 60C. For this method of heat recovery, the desuperheater is fitted in series with the condenser circuit. The desuperheater recovers heat from the higher-temperature super-heated refrigerant gas at the compressor outlet; only the heat of compression is captured. An alternative approach to using a conventional chiller and boiler system is to use a reversible electric-powered heat pump to provide both cooling and heating. The benefit of this solution is that there is no need for a gas boiler and, consequently, no need for a gas connection, which can simplify the hydronic system design and reduce the amount of plant space required, and save on costs. In addition, maintenance and controls are rationalised, which can also save on capital costs. According to Mitsubishi Electric, the long-term operating costs of this type of system can be significantly lower than a chiller-boiler combination, and energy savings are claimed to be up to 40%. Integrated heat recovery electric heat pumps are available that contain the usual heat pump elements of compressor, evaporator and condenser, as well as additional auxiliary exchangers to enable the chiller to capture heat from the cooling system for use elsewhere in the building. In Mays CIBSE Journal, we featured Joel Gustafsson Consultings proposed scheme for the Mill Lane redevelopment in Cambridge. The scheme is one of the first in a new wave of large-scale projects where site-wide heating and cooling is supplied by electric-powered air source heat pumps. The heat pumps incorporate a heat recovery feature, which enables heat removed by the heat pump in cooling Heat recovery chillers capture heat that would otherwise be wasted, and use it for heating minimising carbon emissions www.cibsejournal.com June 2021 57 CIBSE June 21 pp57-58 Heat recovery chiller.indd 57 21/05/2021 17:56