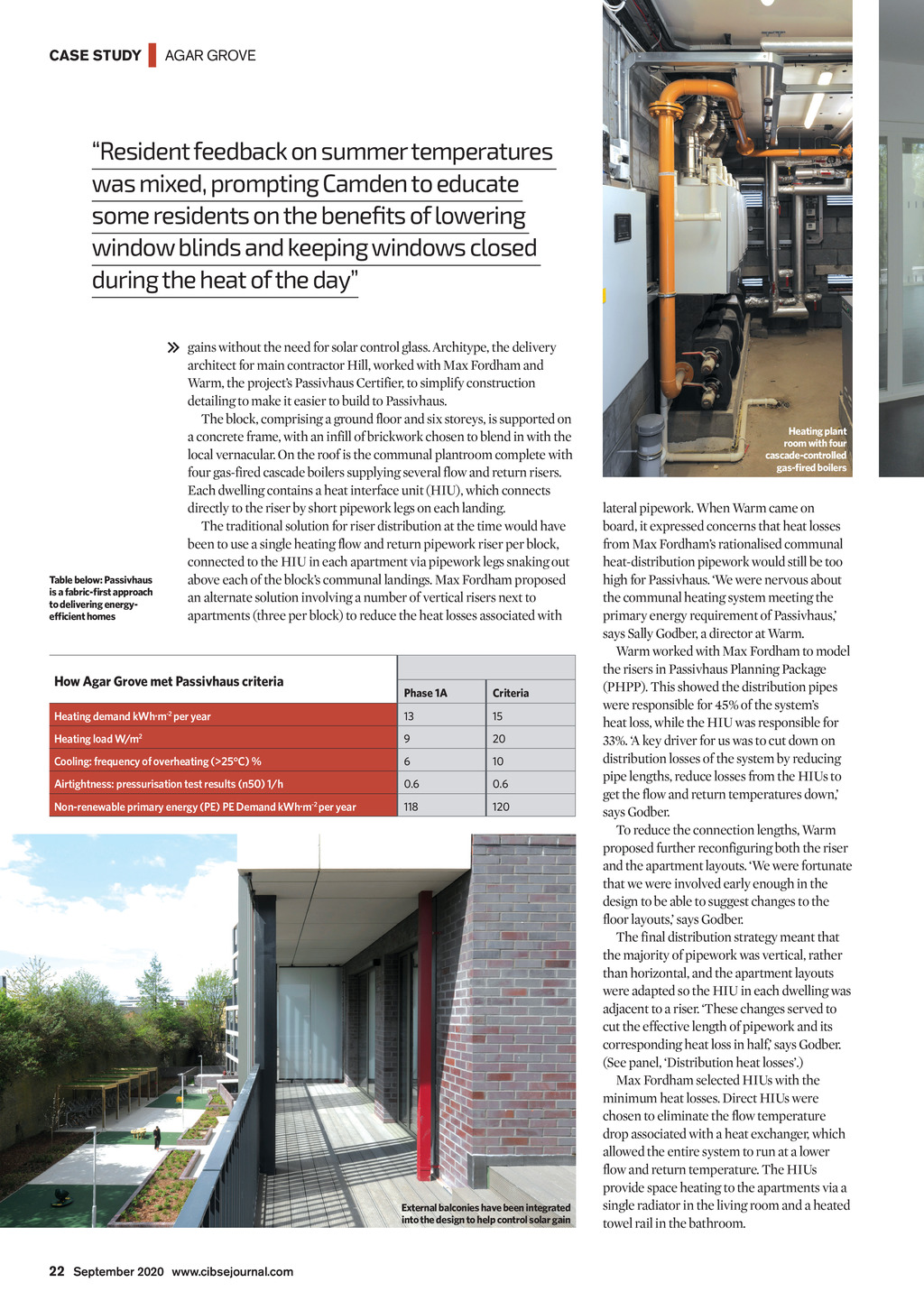

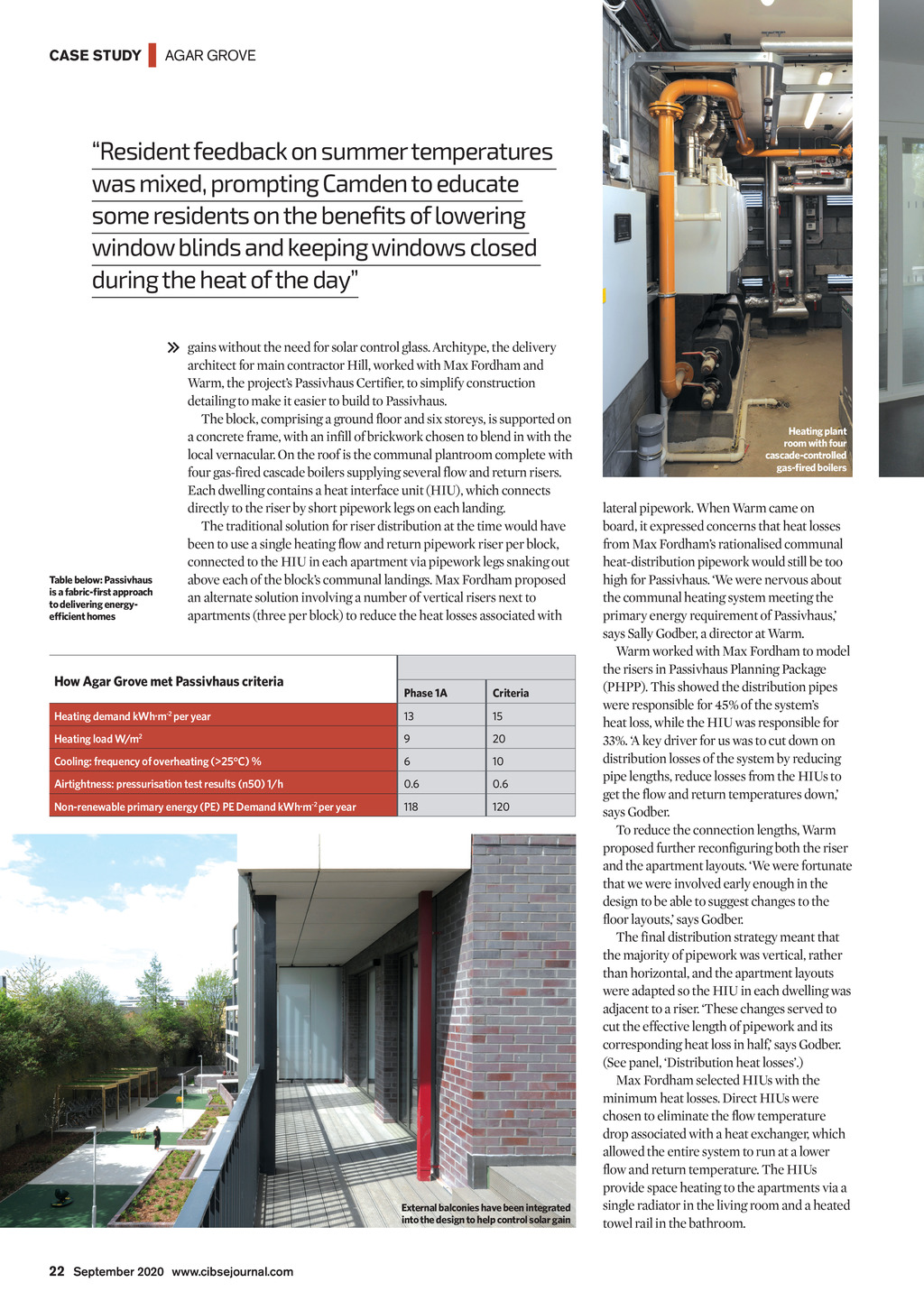

CASE STUDY | AGAR GROVE Resident feedback on summer temperatures was mixed, prompting Camden to educate some residents on the benefits of lowering window blinds and keeping windows closed during the heat of the day Table below: Passivhaus is a fabric-first approach to delivering energyefficient homes gains without the need for solar control glass. Architype, the delivery architect for main contractor Hill, worked with Max Fordham and Warm, the projects Passivhaus Certifier, to simplify construction detailing to make it easier to build to Passivhaus. The block, comprising a ground floor and six storeys, is supported on a concrete frame, with an infill of brickwork chosen to blend in with the local vernacular. On the roof is the communal plantroom complete with four gas-fired cascade boilers supplying several flow and return risers. Each dwelling contains a heat interface unit (HIU), which connects directly to the riser by short pipework legs on each landing. The traditional solution for riser distribution at the time would have been to use a single heating flow and return pipework riser per block, connected to the HIU in each apartment via pipework legs snaking out above each of the blocks communal landings. Max Fordham proposed an alternate solution involving a number of vertical risers next to apartments (three per block) to reduce the heat losses associated with How Agar Grove met Passivhaus criteria Phase 1A Criteria Heating demand kWh.m-2 per year 13 15 Heating load W/m 9 20 Cooling: frequency of overheating (>25C) % 6 10 Airtightness: pressurisation test results (n50) 1/h 0.6 0.6 Non-renewable primary energy (PE) PE Demand kWh.m-2 per year 118 120 2 External balconies have been integrated into the design to help control solar gain Heating plant room with four cascade-controlled gas-fired boilers lateral pipework. When Warm came on board, it expressed concerns that heat losses from Max Fordhams rationalised communal heat-distribution pipework would still be too high for Passivhaus. We were nervous about the communal heating system meeting the primary energy requirement of Passivhaus, says Sally Godber, a director at Warm. Warm worked with Max Fordham to model the risers in Passivhaus Planning Package (PHPP). This showed the distribution pipes were responsible for 45% of the systems heat loss, while the HIU was responsible for 33%. A key driver for us was to cut down on distribution losses of the system by reducing pipe lengths, reduce losses from the HIUs to get the flow and return temperatures down, says Godber. To reduce the connection lengths, Warm proposed further reconfiguring both the riser and the apartment layouts. We were fortunate that we were involved early enough in the design to be able to suggest changes to the floor layouts, says Godber. The final distribution strategy meant that the majority of pipework was vertical, rather than horizontal, and the apartment layouts were adapted so the HIU in each dwelling was adjacent to a riser. These changes served to cut the effective length of pipework and its corresponding heat loss in half, says Godber. (See panel, Distribution heat losses.) Max Fordham selected HIUs with the minimum heat losses. Direct HIUs were chosen to eliminate the flow temperature drop associated with a heat exchanger, which allowed the entire system to run at a lower flow and return temperature. The HIUs provide space heating to the apartments via a single radiator in the living room and a heated towel rail in the bathroom. 22 September 2020 www.cibsejournal.com CIBSE September 2020 p20-24 Agar Grove.indd 22 21/08/2020 14:54