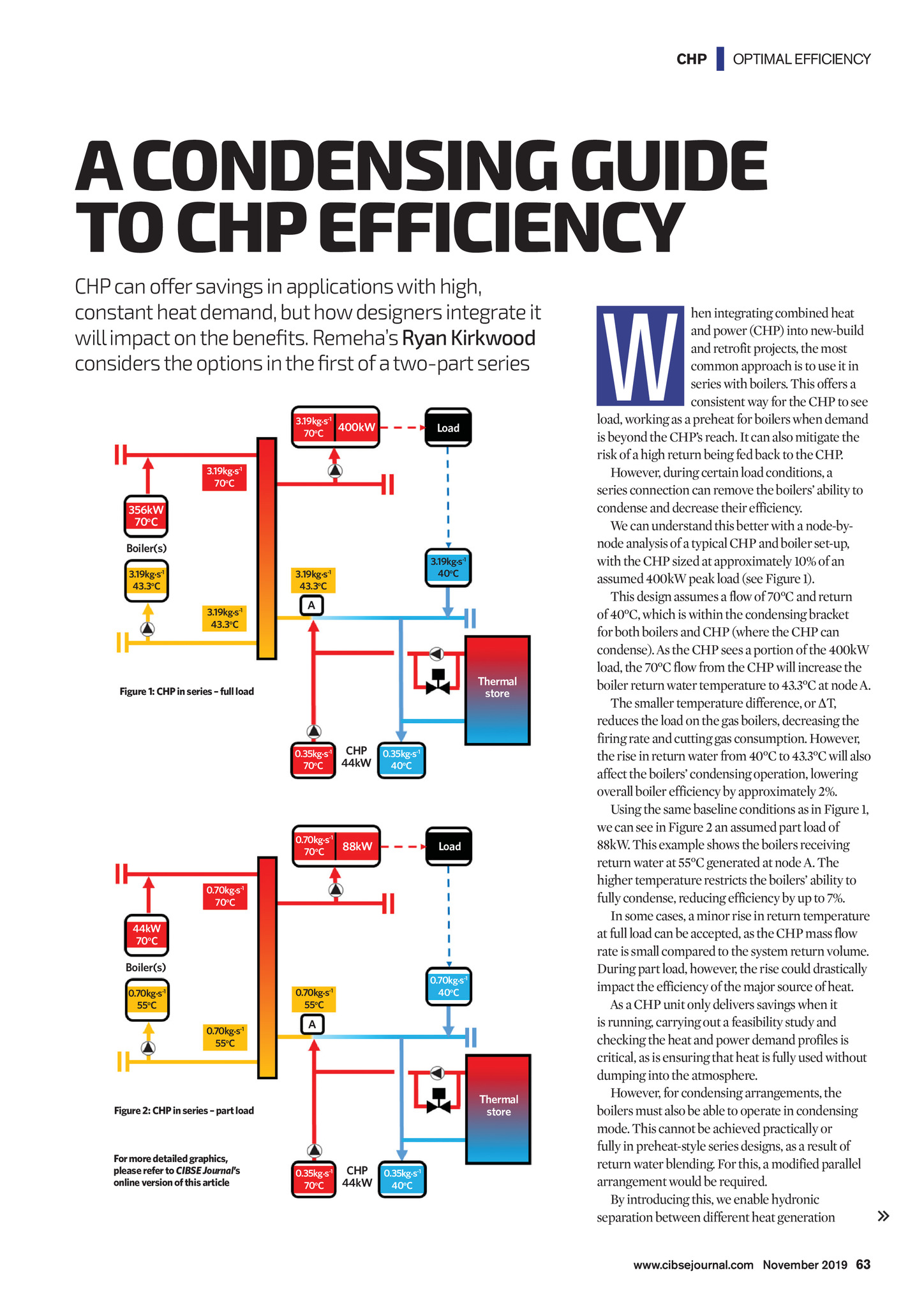

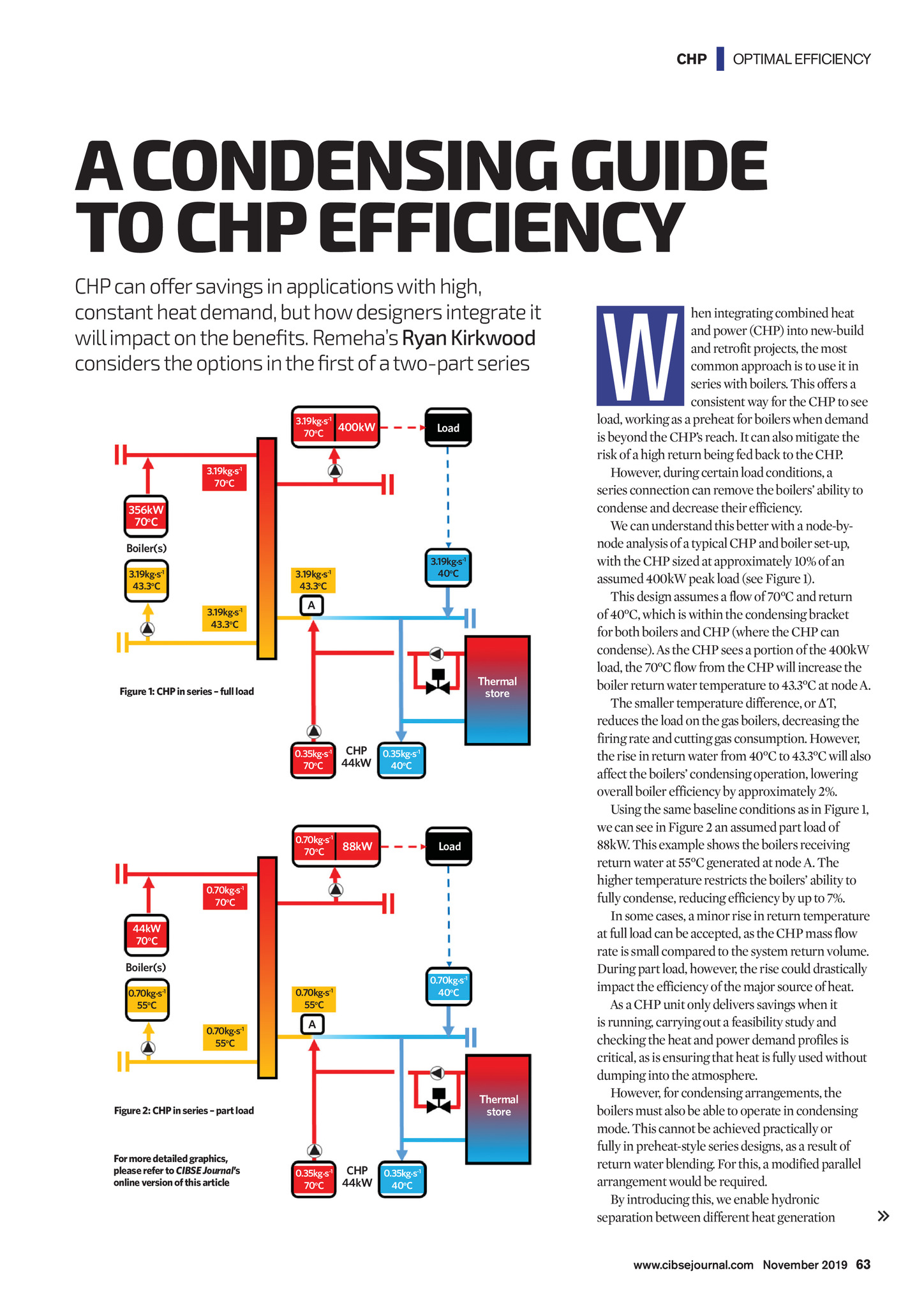

CHP | OPTIMAL EFFICIENCY A CONDENSING GUIDE TO CHP EFFICIENCY CHP can offer savings in applications with high, constant heat demand, but how designers integrate it will impact on the benefits. Remehas Ryan Kirkwood considers the options in the first of a two-part series 3.19kg.s-1 400kW 70oC Load 3.19kg.s-1 70oC 356kW 70oC Boiler(s) 3.19kg.s-1 43.3oC 3.19kg.s-1 40oC 3.19kg.s-1 43.3oC 3.19kg.s-1 43.3oC A Thermal store Figure 1: CHP in series full load 0.35kg.s-1 CHP 44kW 70oC 0.35kg.s-1 40oC 0.70kg.s-1 88kW 70oC Load 0.70kg.s-1 70oC 44kW 70oC Boiler(s) 0.70kg.s-1 40oC 0.70kg.s-1 55oC 0.70kg.s-1 55oC 0.70kg.s-1 55oC A Thermal store Figure 2: CHP in series part load For more detailed graphics, please refer to CIBSE Journals online version of this article 0.35kg.s-1 CHP 44kW 70oC 0.35kg.s-1 40oC W hen integrating combined heat and power (CHP) into new-build and retrofit projects, the most common approach is to use it in series with boilers. This offers a consistent way for the CHP to see load, working as a preheat for boilers when demand is beyond the CHPs reach. It can also mitigate the risk of a high return being fed back to the CHP. However, during certain load conditions, a series connection can remove the boilers ability to condense and decrease their efficiency. We can understand this better with a node-bynode analysis of a typical CHP and boiler set-up, with the CHP sized at approximately 10% of an assumed 400kW peak load (see Figure 1). This design assumes a flow of 70C and return of 40C, which is within the condensing bracket for both boilers and CHP (where the CHP can condense). As the CHP sees a portion of the 400kW load, the 70C flow from the CHP will increase the boiler return water temperature to 43.3C at node A. The smaller temperature difference, or T, reduces the load on the gas boilers, decreasing the firing rate and cutting gas consumption. However, the rise in return water from 40C to 43.3C will also affect the boilers condensing operation, lowering overall boiler efficiency by approximately 2%. Using the same baseline conditions as in Figure 1, we can see in Figure 2 an assumed part load of 88kW. This example shows the boilers receiving return water at 55C generated at node A. The higher temperature restricts the boilers ability to fully condense, reducing efficiency by up to 7%. In some cases, a minor rise in return temperature at full load can be accepted, as the CHP mass flow rate is small compared to the system return volume. During part load, however, the rise could drastically impact the efficiency of the major source of heat. As a CHP unit only delivers savings when it is running, carrying out a feasibility study and checking the heat and power demand profiles is critical, as is ensuring that heat is fully used without dumping into the atmosphere. However, for condensing arrangements, the boilers must also be able to operate in condensing mode. This cannot be achieved practically or fully in preheat-style series designs, as a result of return water blending. For this, a modified parallel arrangement would be required. By introducing this, we enable hydronic separation between different heat generation www.cibsejournal.com November 2019 63 CIBSE Nov19 pp63-64 Rehema.indd 63 25/10/2019 18:03