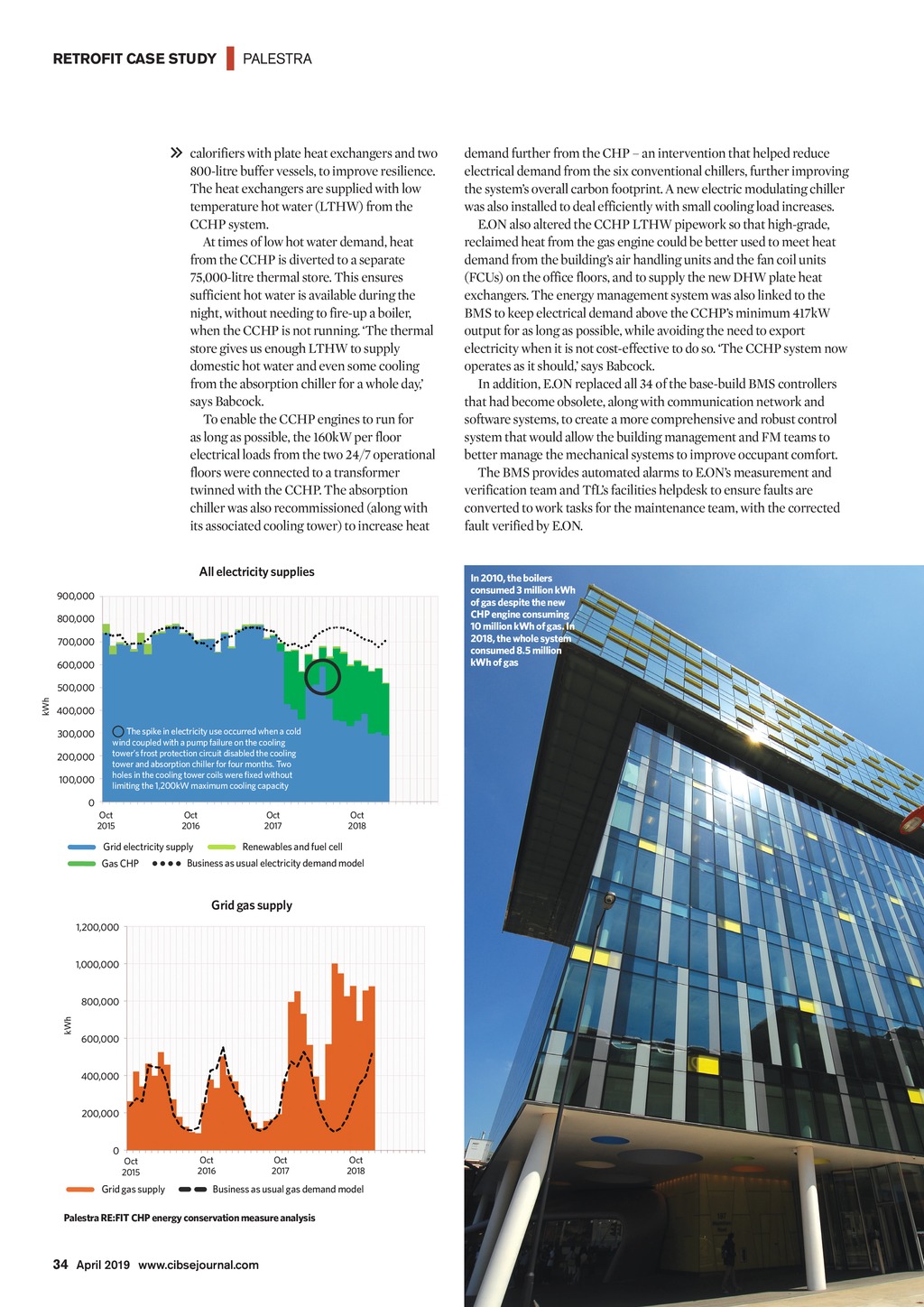

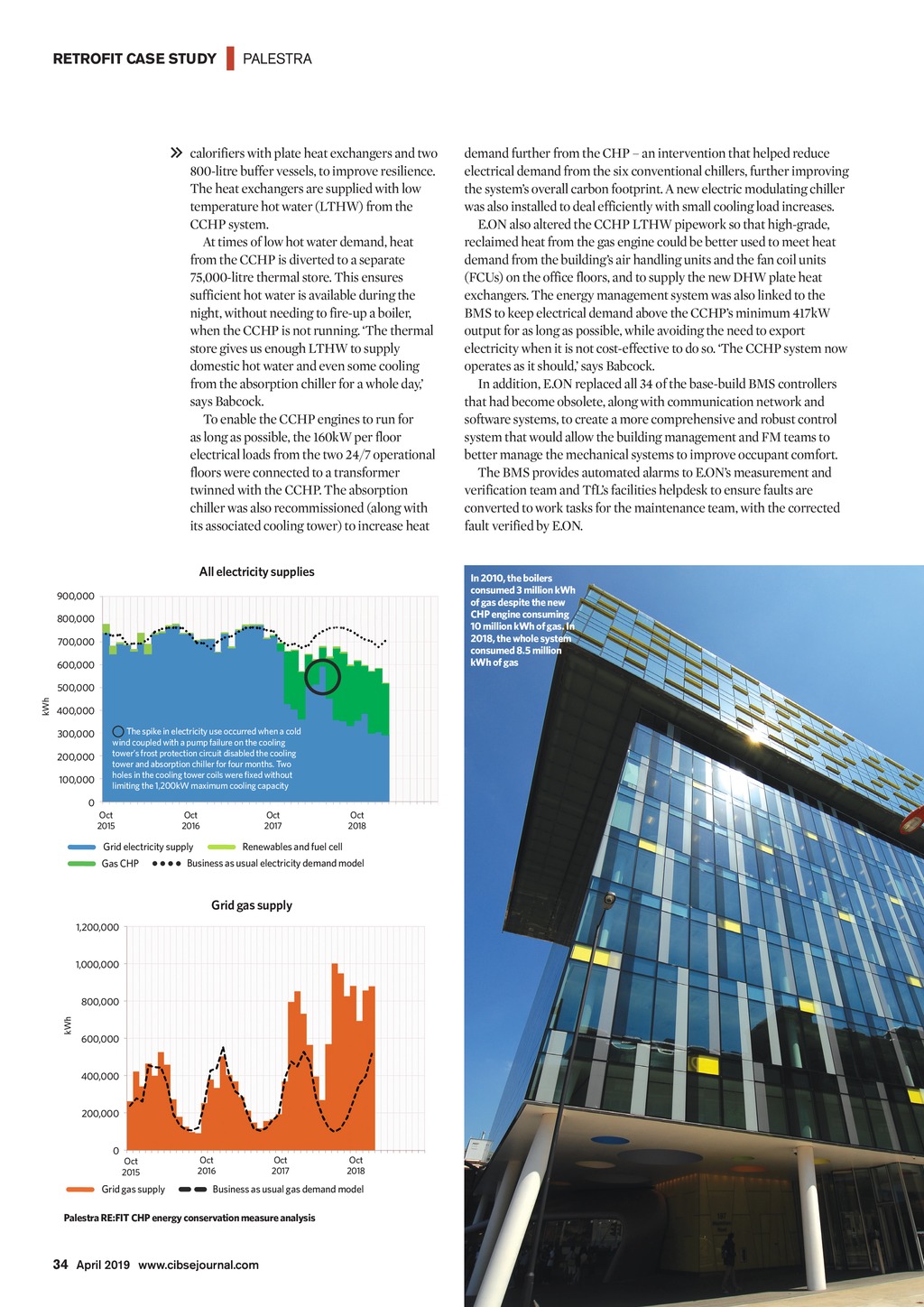

RETROFIT CASE STUDY | PALESTRA calorifiers with plate heat exchangers and two 800-litre buffer vessels, to improve resilience. The heat exchangers are supplied with low temperature hot water (LTHW) from the CCHP system. At times of low hot water demand, heat from the CCHP is diverted to a separate 75,000-litre thermal store. This ensures sufficient hot water is available during the night, without needing to fire-up a boiler, when the CCHP is not running. The thermal store gives us enough LTHW to supply domestic hot water and even some cooling from the absorption chiller for a whole day, says Babcock. To enable the CCHP engines to run for as long as possible, the 160kW per floor electrical loads from the two 24/7 operational floors were connected to a transformer twinned with the CCHP. The absorption chiller was also recommissioned (along with its associated cooling tower) to increase heat All electricity supplies demand further from the CHP an intervention that helped reduce electrical demand from the six conventional chillers, further improving the systems overall carbon footprint. A new electric modulating chiller was also installed to deal efficiently with small cooling load increases. E.ON also altered the CCHP LTHW pipework so that high-grade, reclaimed heat from the gas engine could be better used to meet heat demand from the buildings air handling units and the fan coil units (FCUs) on the office floors, and to supply the new DHW plate heat exchangers. The energy management system was also linked to the BMS to keep electrical demand above the CCHPs minimum 417kW output for as long as possible, while avoiding the need to export electricity when it is not cost-effective to do so. The CCHP system now operates as it should, says Babcock. In addition, E.ON replaced all 34 of the base-build BMS controllers that had become obsolete, along with communication network and software systems, to create a more comprehensive and robust control system that would allow the building management and FM teams to better manage the mechanical systems to improve occupant comfort. The BMS provides automated alarms to E.ONs measurement and verification team and TfLs facilities helpdesk to ensure faults are converted to work tasks for the maintenance team, with the corrected fault verified by E.ON. In 2010, the boilers consumed 3 million kWh of gas despite the new CHP engine consuming 10 million kWh of gas. In 2018, the whole system consumed 8.5 million kWh of gas 900,000 800,000 700,000 600,000 kWh 500,000 400,000 300,000 200,000 100,000 The spike in electricity use occurred when a cold wind coupled with a pump failure on the cooling towers frost protection circuit disabled the cooling tower and absorption chiller for four months. Two holes in the cooling tower coils were fixed without limiting the 1,200kW maximum cooling capacity 0 Oct 2015 Oct 2016 Oct 2017 Renewables and fuel cell Grid electricity supply Gas CHP Oct 2018 Business as usual electricity demand model Grid gas supply 1,200,000 1,000,000 kWh 800,000 600,000 400,000 200,000 0 Oct 2015 Grid gas supply Oct 2016 Oct 2017 Oct 2018 Business as usual gas demand model Palestra RE:FIT CHP energy conservation measure analysis 34 April 2019 www.cibsejournal.com CIBSE Apr19 pp32-36 Palestra.indd 34 22/03/2019 16:55