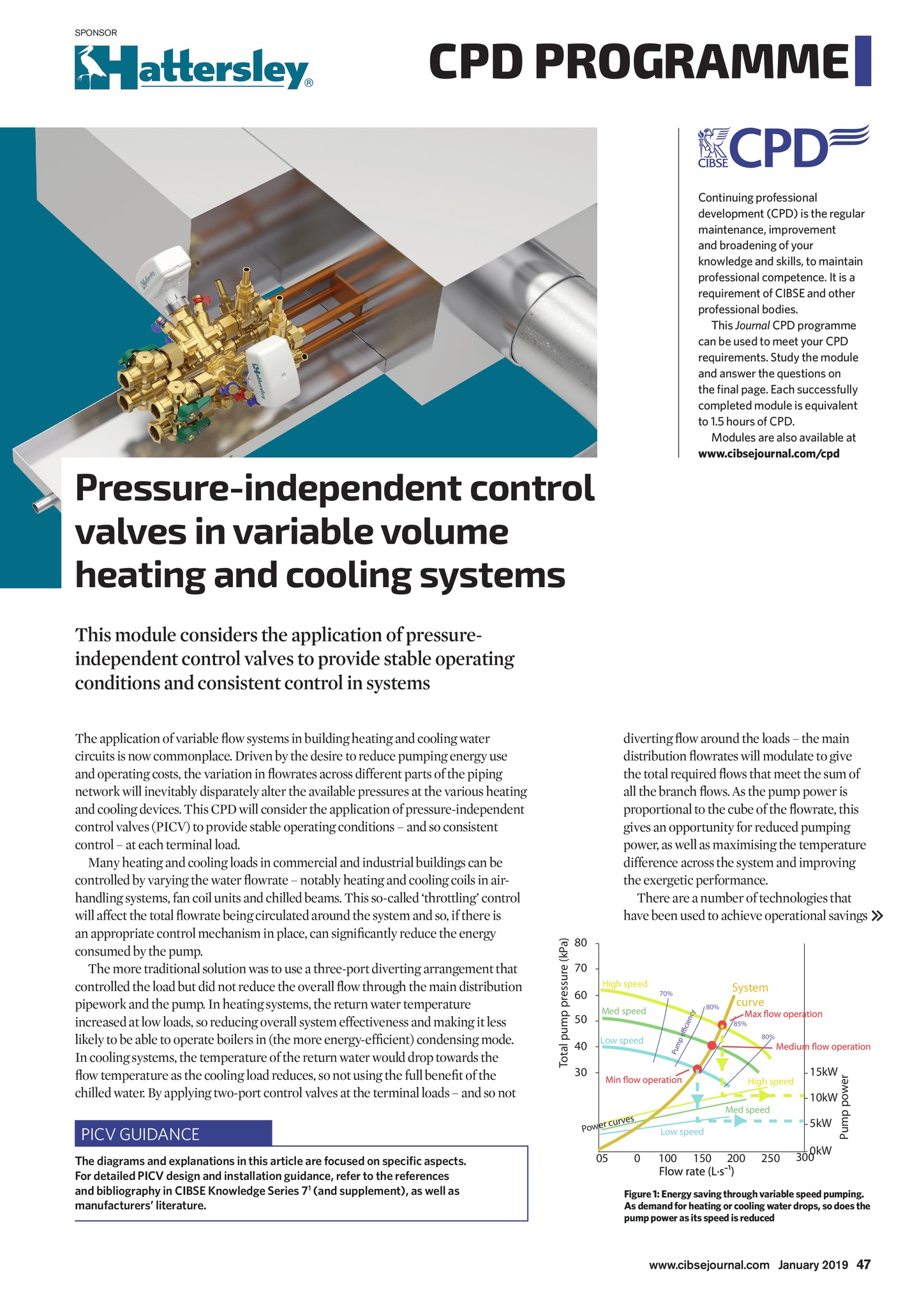

SPONSOR CPD PROGRAMME Continuing professional development (CPD) is the regular maintenance, improvement and broadening of your knowledge and skills, to maintain professional competence. It is a requirement of CIBSE and other professional bodies. This Journal CPD programme can be used to meet your CPD requirements. Study the module and answer the questions on the final page. Each successfully completed module is equivalent to 1.5 hours of CPD. Modules are also available at www.cibsejournal.com/cpd Pressure-independent control valves in variable volume heating and cooling systems This module considers the application of pressureindependent control valves to provide stable operating conditions and consistent control in systems The diagrams and explanations in this article are focused on specific aspects. For detailed PICV design and installation guidance, refer to the references and bibliography in CIBSE Knowledge Series 71 (and supplement), as well as manufacturers literature. 80 70 60 50 40 High speed 70% 80% Med speed System curve 85% 80% Low speed 30 High speed curves Power 05 0 Med speed 150 10kW 5kW Low speed 100 15kW 200 250 Pump power PICV GUIDANCE diverting flow around the loads the main distribution flowrates will modulate to give the total required flows that meet the sum of all the branch flows. As the pump power is proportional to the cube of the flowrate, this gives an opportunity for reduced pumping power, as well as maximising the temperature difference across the system and improving the exergetic performance. There are a number of technologies that have been used to achieve operational savings Total pump pressure (kPa) The application of variable flow systems in building heating and cooling water circuits is now commonplace. Driven by the desire to reduce pumping energy use and operating costs, the variation in flowrates across different parts of the piping network will inevitably disparately alter the available pressures at the various heating and cooling devices. This CPD will consider the application of pressure-independent control valves (PICV) to provide stable operating conditions and so consistent control at each terminal load. Many heating and cooling loads in commercial and industrial buildings can be controlled by varying the water flowrate notably heating and cooling coils in airhandling systems, fan coil units and chilled beams. This so-called throttling control will affect the total flowrate being circulated around the system and so, if there is an appropriate control mechanism in place, can significantly reduce the energy consumed by the pump. The more traditional solution was to use a three-port diverting arrangement that controlled the load but did not reduce the overall flow through the main distribution pipework and the pump. In heating systems, the return water temperature increased at low loads, so reducing overall system effectiveness and making it less likely to be able to operate boilers in (the more energy-efficient) condensing mode. In cooling systems, the temperature of the return water would drop towards the flow temperature as the cooling load reduces, so not using the full benefit of the chilled water. By applying two-port control valves at the terminal loads and so not 0kW 300 Figure 1: Energy saving through variable speed pumping. As demand for heating or cooling water drops, so does the pump power as its speed is reduced www.cibsejournal.com January 2019 47 CIBSE Jan19 pp47-50 CPD 4.indd 47 21/12/2018 15:13