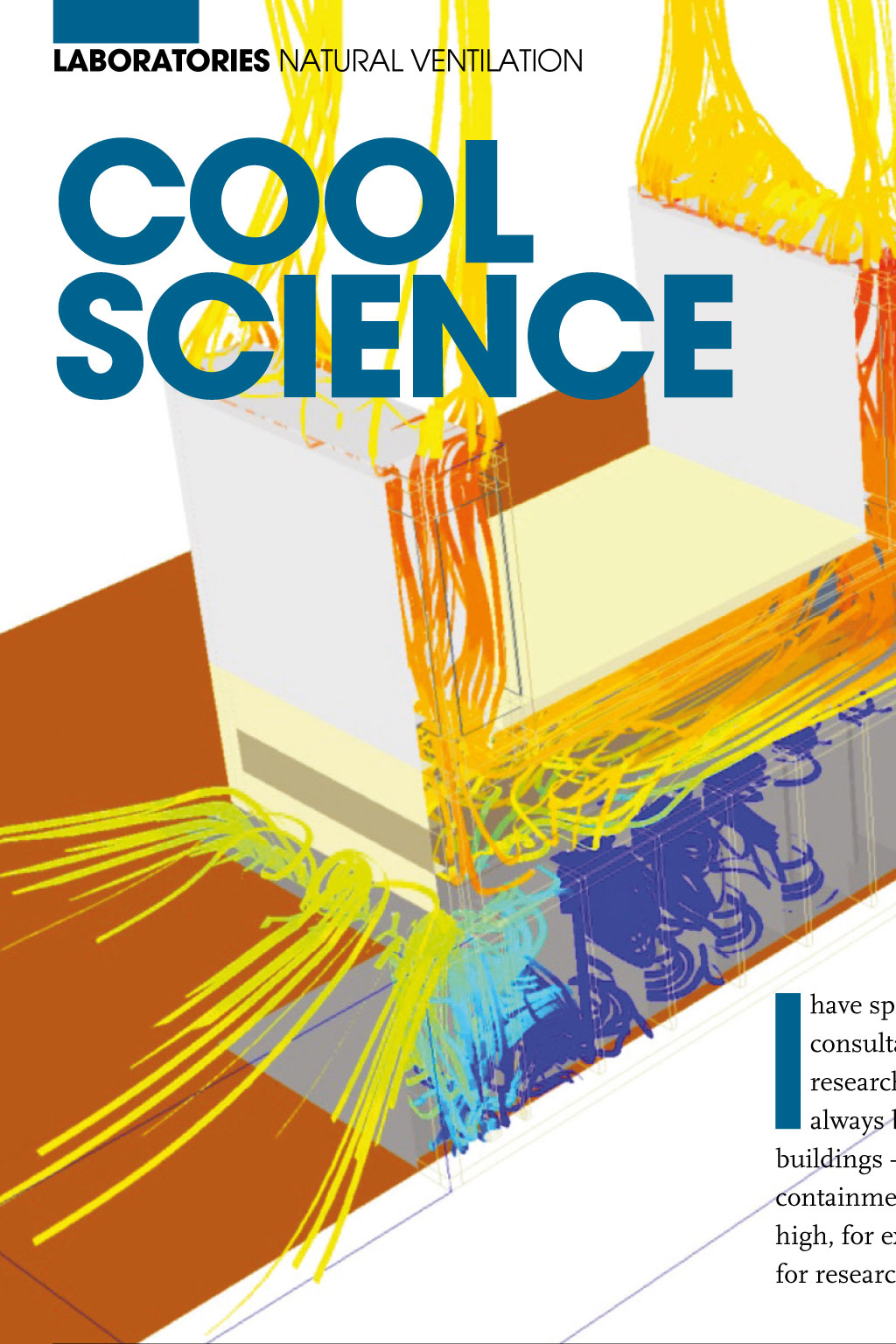

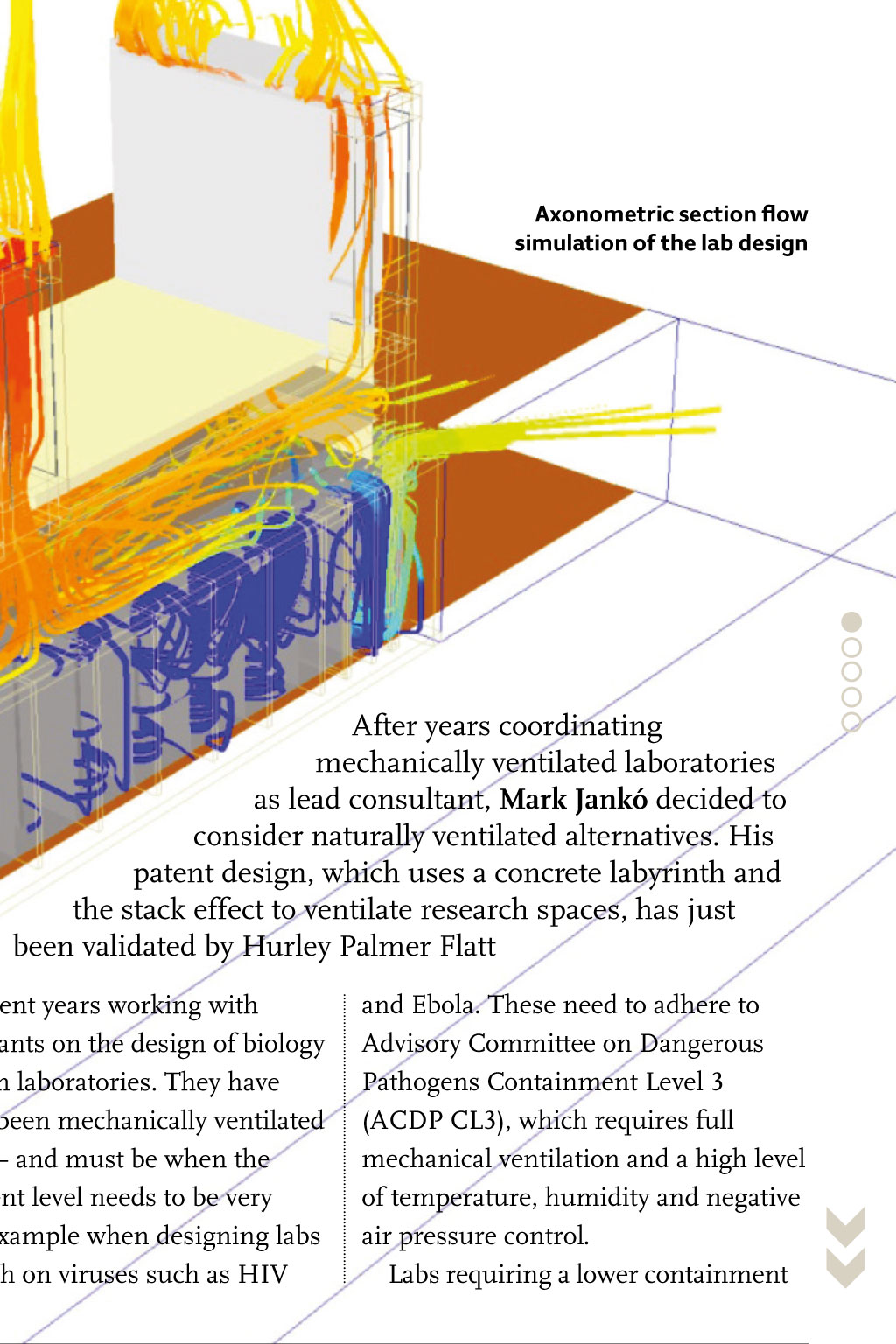

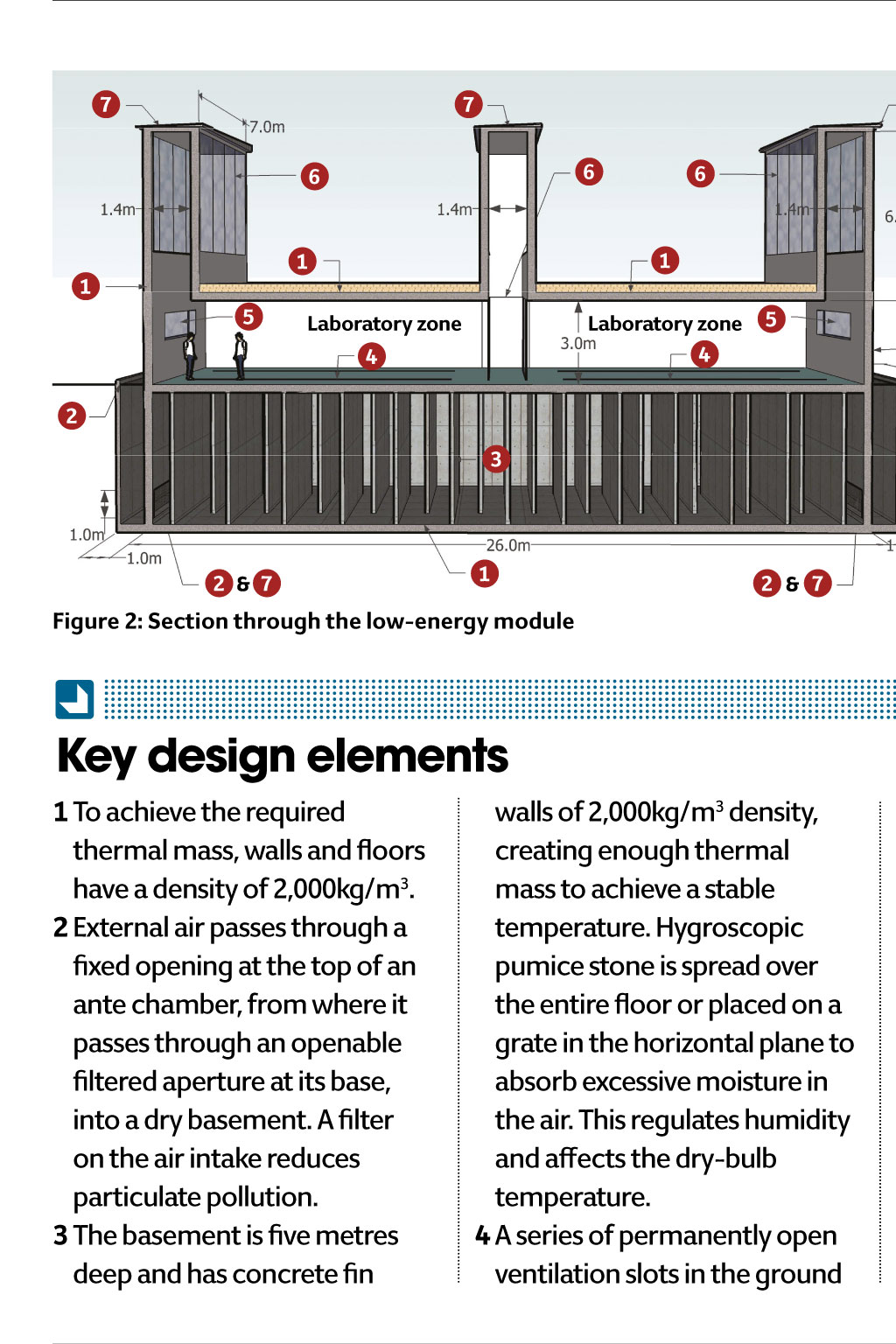

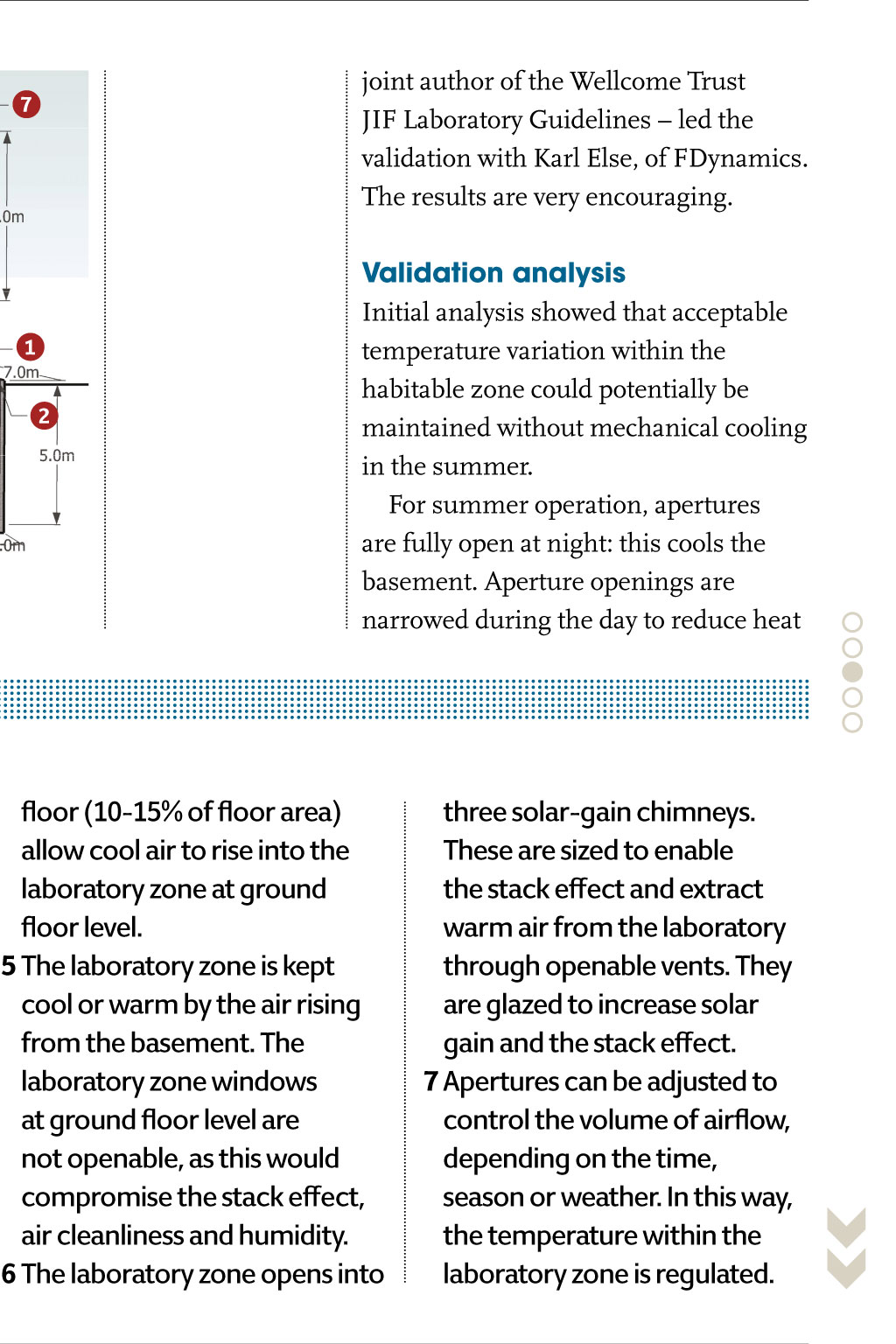

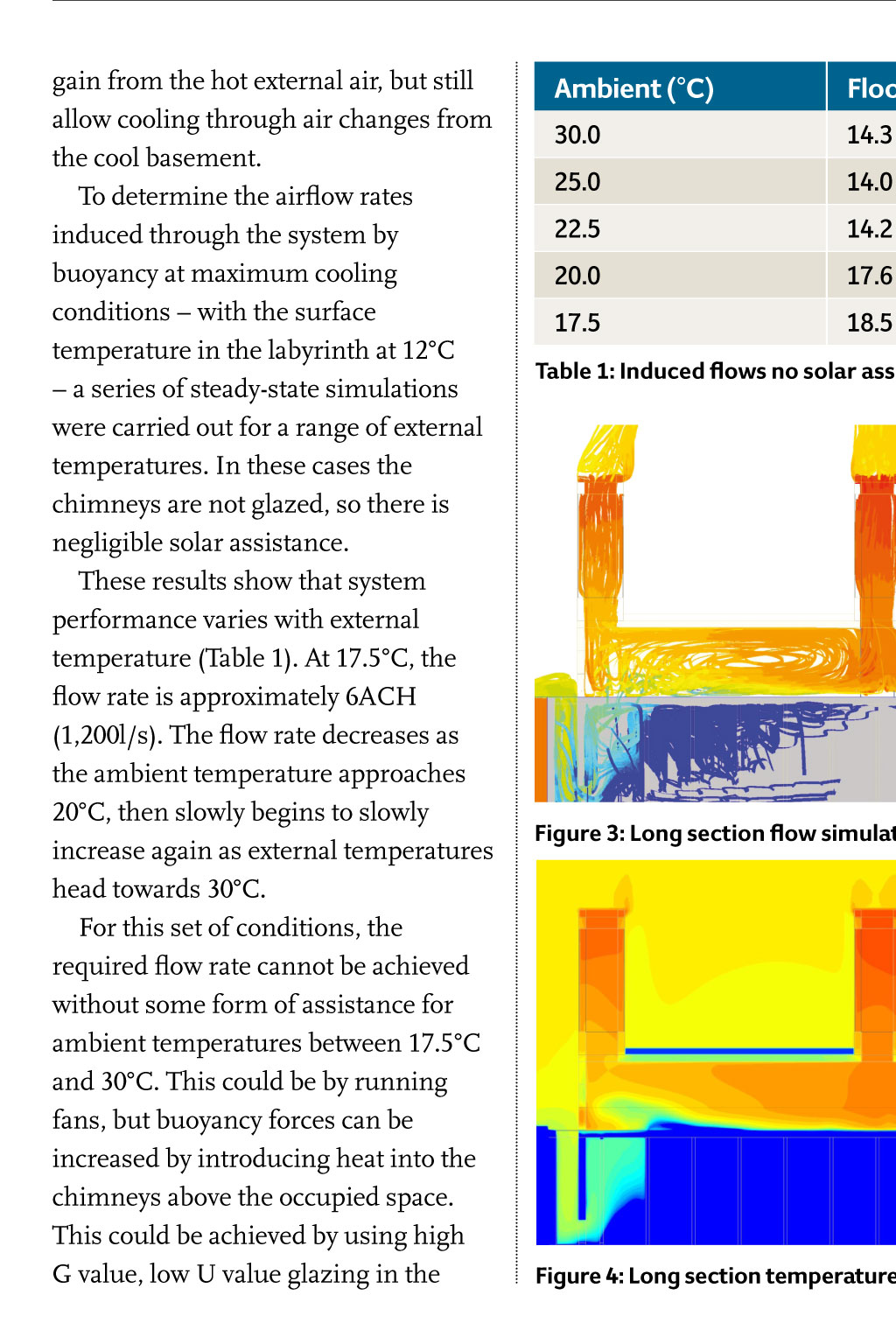

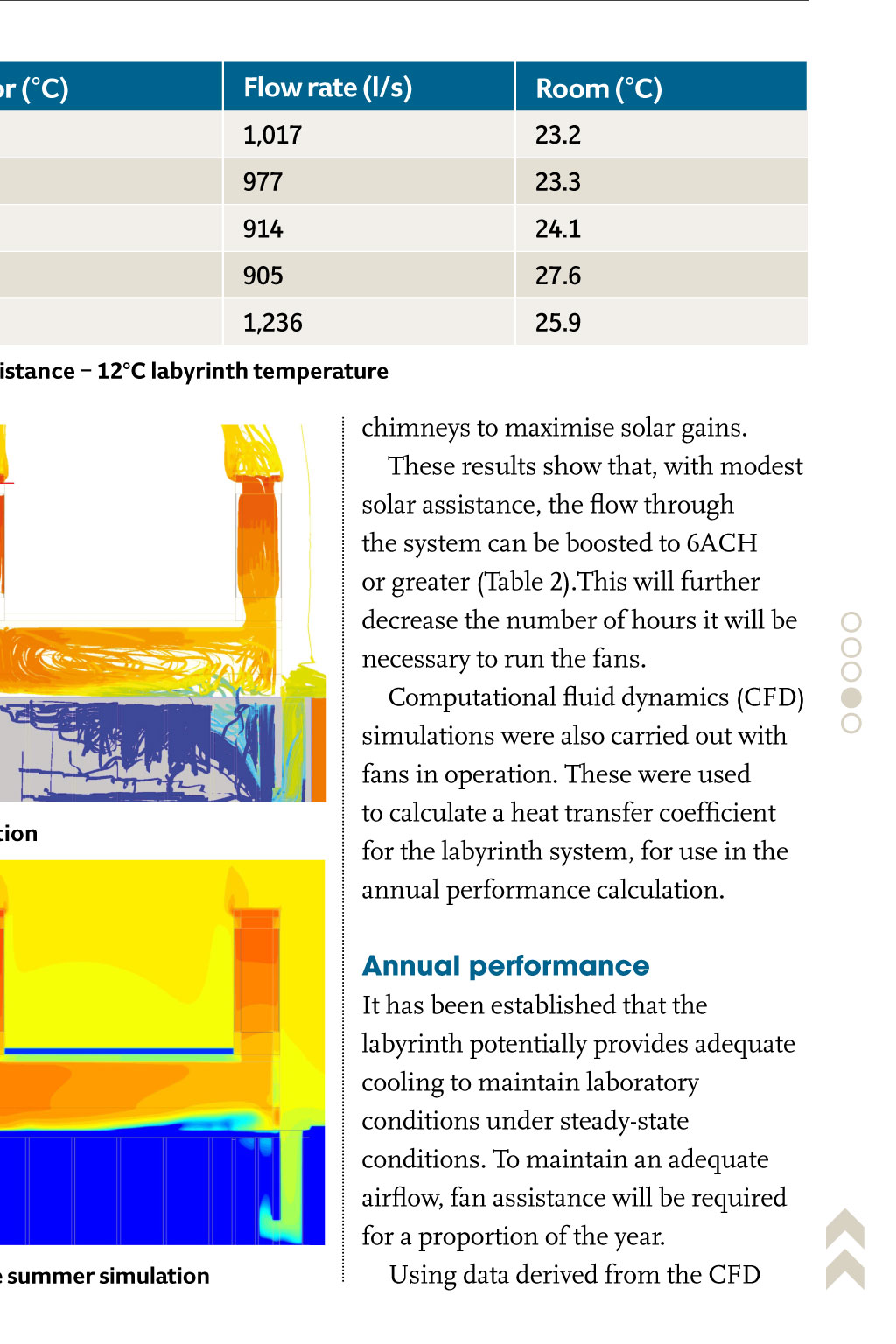

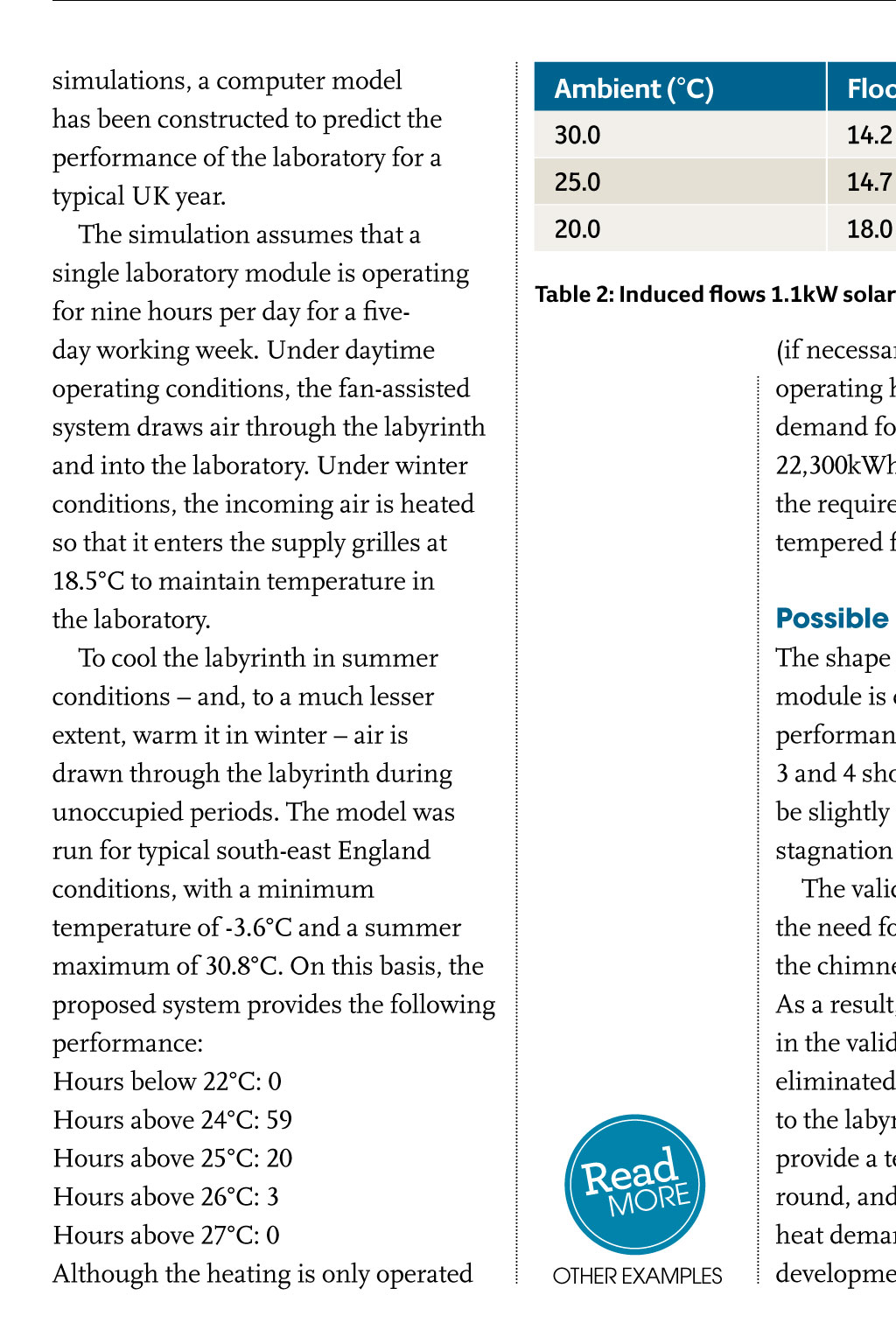

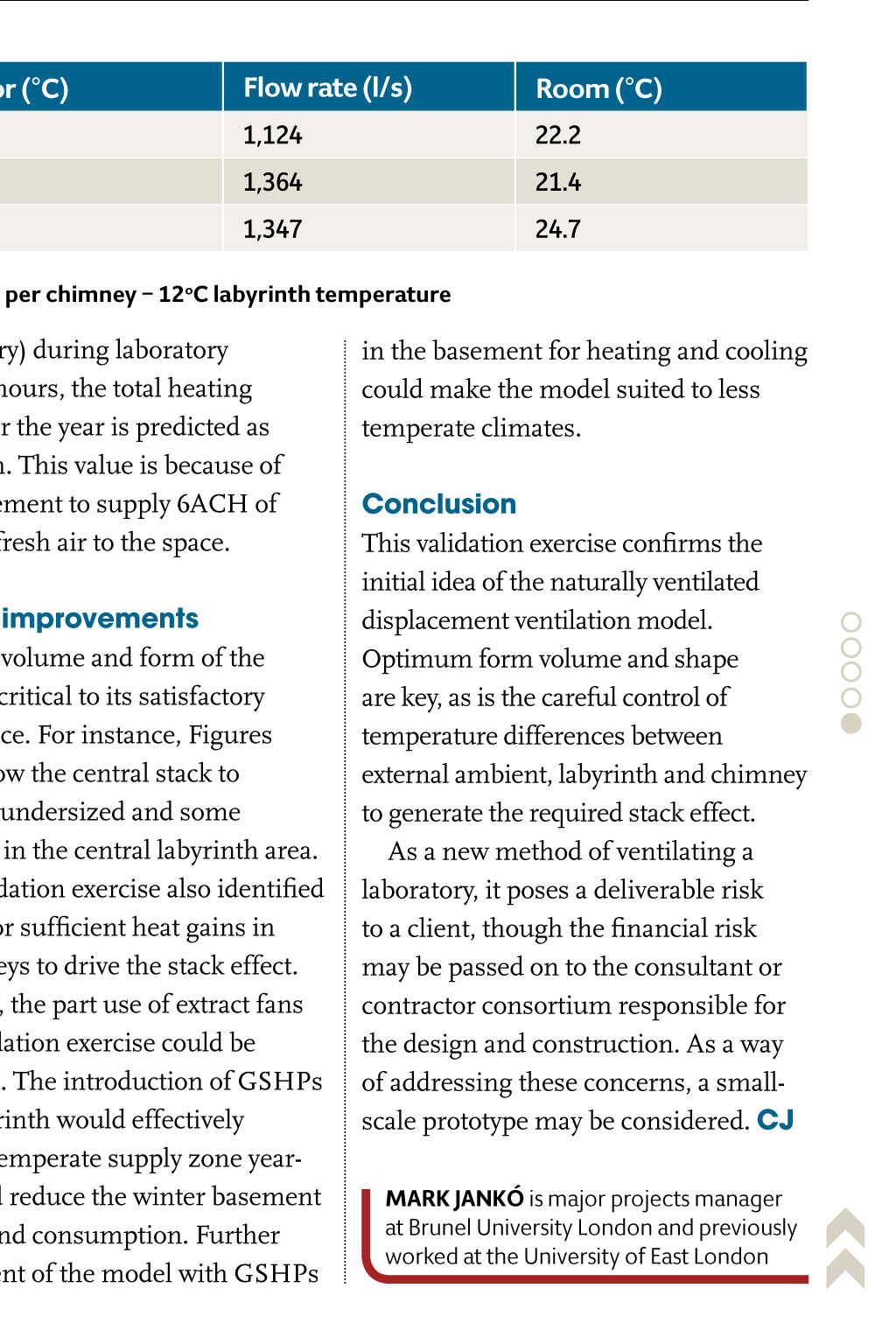

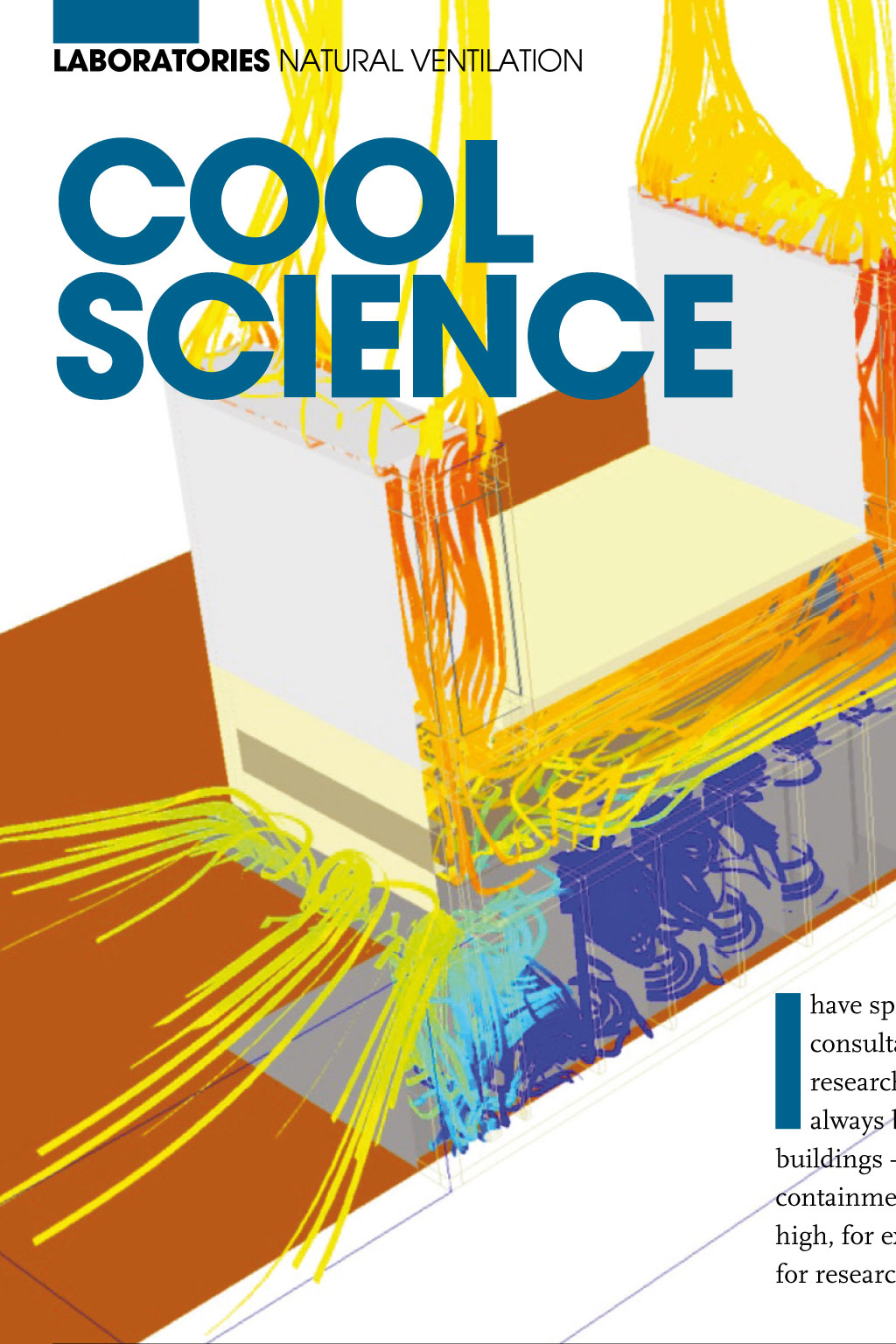

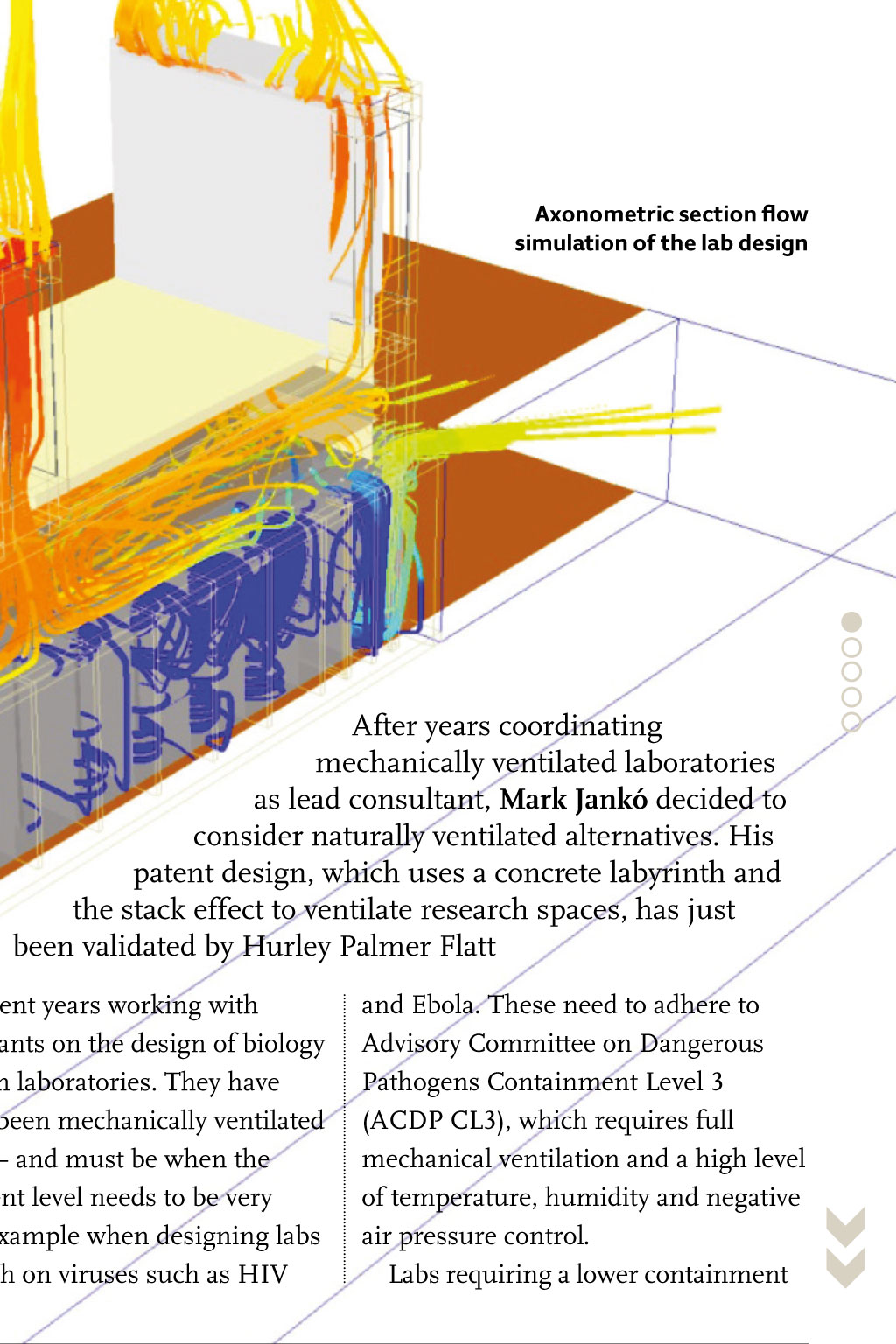

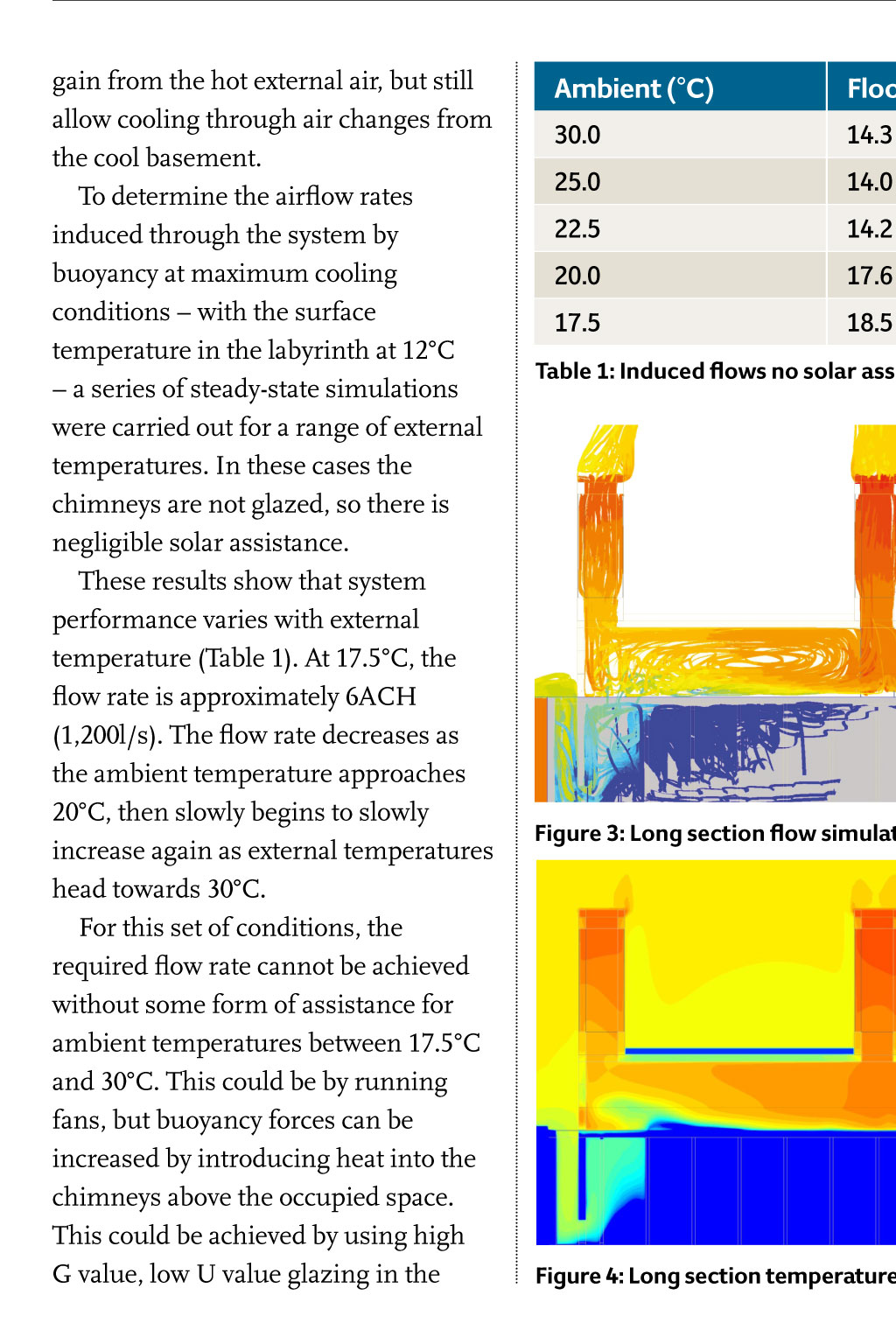

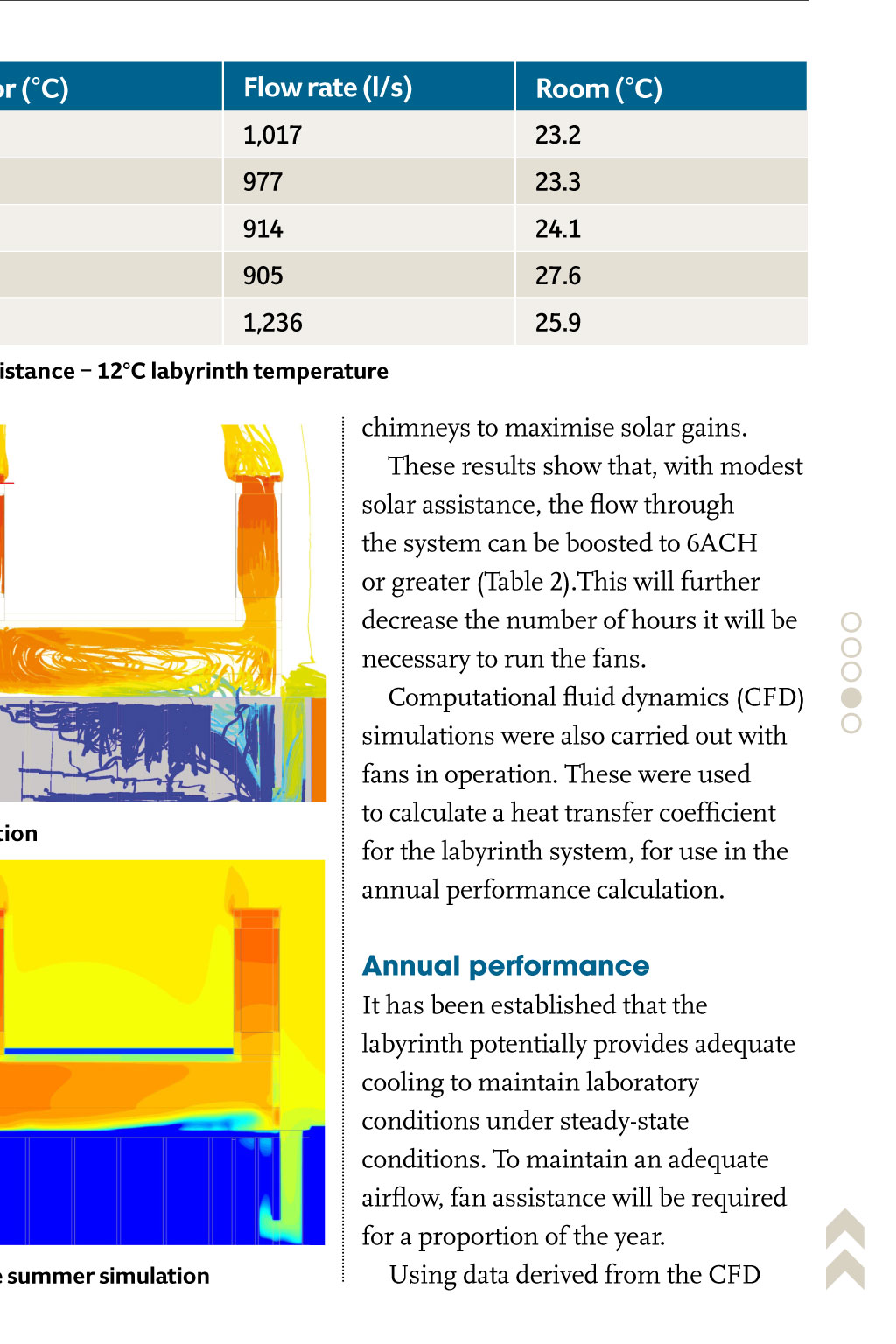

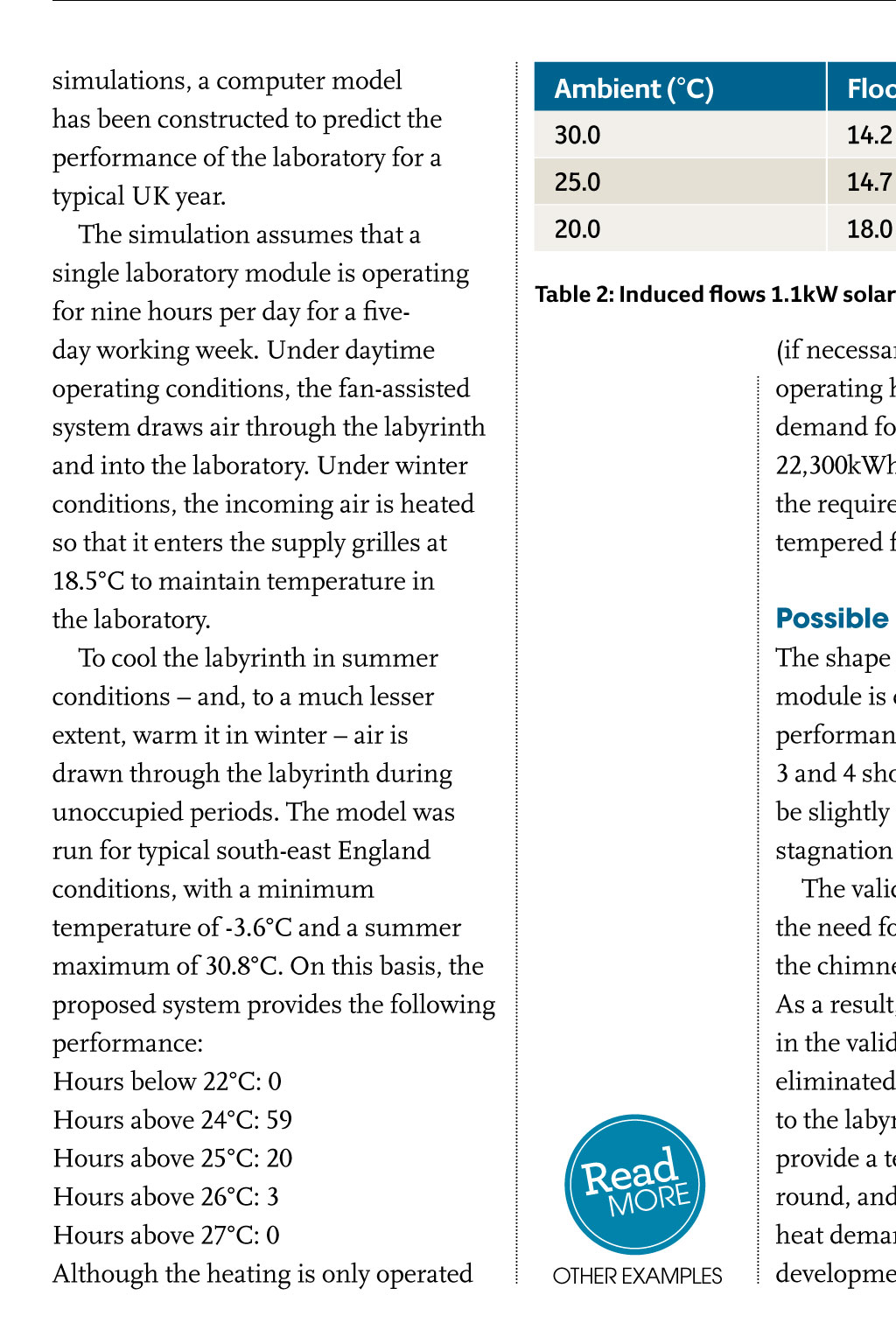

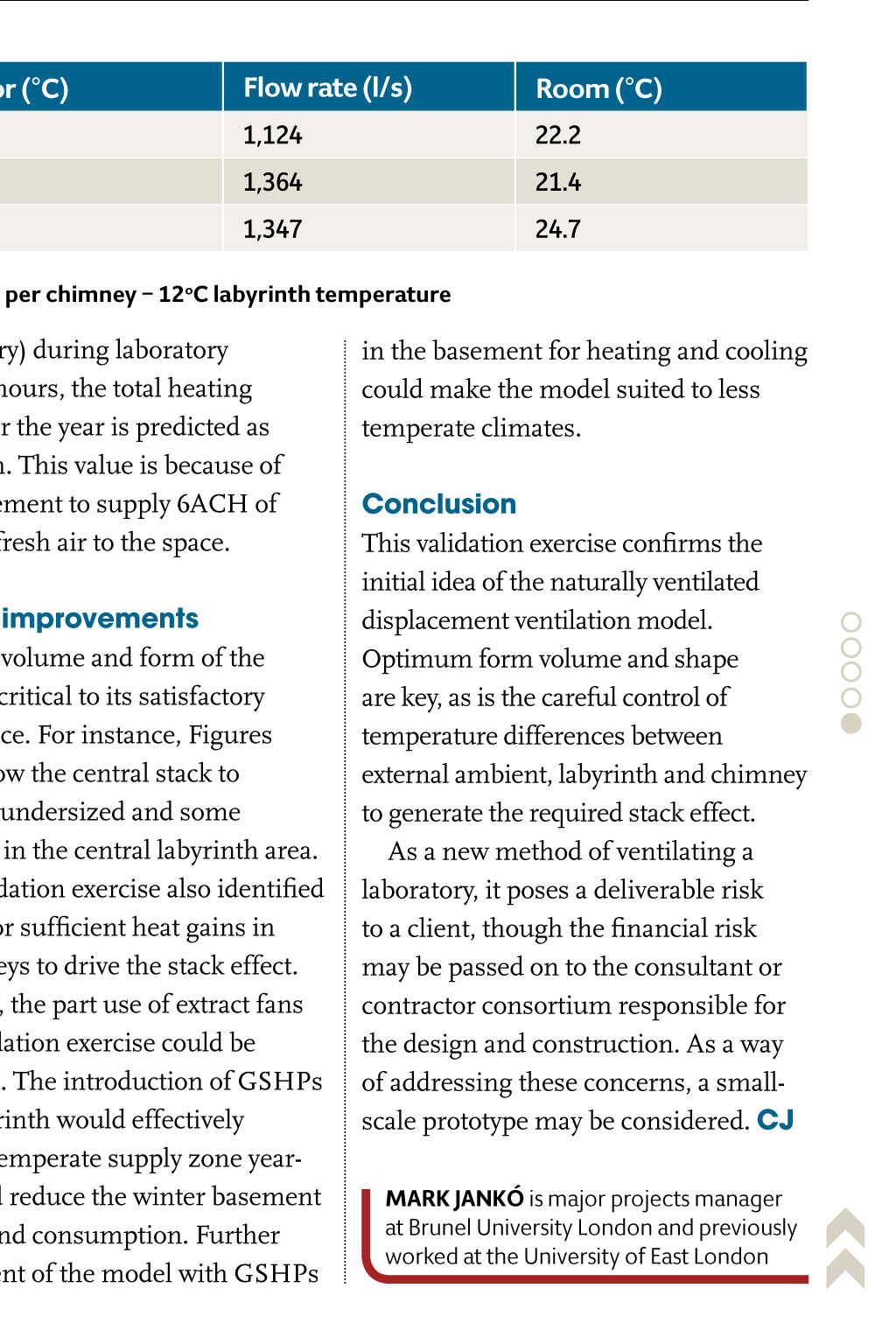

LABORATORIES NATURAL VENTILATION COOL SCIENCE Axonometric section flow simulation of the lab design DESIGN CRITERIA - During occupied hours the laboratory space will require an air exchange rate of 6ACH (which is approximately 1,200l/s for the single module considered here) - Filtration will be required - Laboratory temperatures maintained between 22C and 24C (or 3C below external ambient, whichever is greater). Assumptions Single labyrinth module: Laboratory heat loads: 60W/m2 Filtration: Filters: Two at 4.5m by 6.8m. Face velocities are low (less than 0.02m/s so losses are negligible) External inlet louvre: 50% free area. level have less stringent requirements. ACDP CL2 facilities only require a controlled flow of air in and out of the space, and a closed door between the lab and other spaces. The complexity of the mechanical systems often used for Class 2 facilities mean they require careful commissioning and maintenance. The risks of underperformance are numerous; for instance, heat gains are underestimated often specification or usage changes and additional constraints may be applied, such as the acoustic enclosure of chillers, which can potentially knock out the laboratory on hot days. For Class 2 laboratories, why not bite the bullet and offer a simple natural ventilation system, which has a few warm-degree days every year, less construction risk and considerably smaller lifecycle costs? In 2009, I started work on an alternative to mechanically ventilated laboratories, which received a UK patent in 2013. It combines a labyrinth with stack ventilation to produce a habitable space in-between, the size of a typical laboratory module (Figure 2). The idea started with a sketch and an initial spreadsheet calculation; 7 After years coordinating mechanically ventilated laboratories as lead consultant, Mark Jank decided to consider naturally ventilated alternatives. His patent design, which uses a concrete labyrinth and the stack effect to ventilate research spaces, has just been validated by Hurley Palmer Flatt I have spent years working with consultants on the design of biology research laboratories. They have always been mechanically ventilated buildings and must be when the containment level needs to be very high, for example when designing labs for research on viruses such as HIV this demonstrated that the sketch was impractical because a considerable height difference was required between the air supply and extract, by way of a deep basement and tall chimney. The benefits are reduced energy consumption and maintenance. There is no mechanical ventilation machinery, save for apertures at the top and bottom of the laboratory. The module does require basement radiators or a ground source heat pump (GSHP) system to regulate the basement temperature through the cool or hot season, depending on the geographic location. The module requires flushing through with large volumes of cool night air, which means it is not a 6 6 1 1 Laboratory zone Laboratory zone Validation analysis Initial analysis showed that acceptable temperature variation within the habitable zone could potentially be maintained without mechanical cooling in the summer. For summer operation, apertures are fully open at night: this cools the basement. Aperture openings are narrowed during the day to reduce heat 5 1 4 4 2 2 3 2 7 1 2 24/7 facility. The airflows are reduced during normal user operating hours to receive the moderated air from the basement. A filter can be applied to the basement inlet aperture to reduce particulate pollution; as the module is a once through air system, it is suited to ACDP CL2 work. Safety cabinets and fume cupboards can be introduced, contained within the stack with fans on the roof, as required. The module is sized to suit a typical laboratory bench layout, using the appropriate circulation guidance dimensions. It consists of two labs with a central island double bench with a 1,500mm circulation space to the two flanking benches on the perimeter walls, the bench depths being 750mm (1,500mm for the double). The module can be repeated indefinitely. Typically, 35-50% of the capital cost of a conventional laboratory is for mechanical services, so omission of complex mechanical ventilation can cover the cost of building the labyrinth basement. Hurley Palmer Flatt recently completed an independent validation, using IES software. Associate director at the engineering consultancy John Gibson who has considerable laboratory-design experience and is joint author of the Wellcome Trust JIF Laboratory Guidelines led the validation with Karl Else, of FDynamics. The results are very encouraging. 7 6 5 DESIGN CRITERIA Figure 1: Initial sketch section 7 1 eadE RMOR and Ebola. These need to adhere to Advisory Committee on Dangerous Pathogens Containment Level 3 (ACDP CL3), which requires full mechanical ventilation and a high level of temperature, humidity and negative air pressure control. Labs requiring a lower containment 7 Figure 2: Section through the low-energy module Key design elements 1 To achieve the required thermal mass, walls and floors have a density of 2,000kg/m3. 2 External air passes through a fixed opening at the top of an ante chamber, from where it passes through an openable filtered aperture at its base, into a dry basement. A filter on the air intake reduces particulate pollution. 3 The basement is five metres deep and has concrete fin walls of 2,000kg/m3 density, creating enough thermal mass to achieve a stable temperature. Hygroscopic pumice stone is spread over the entire floor or placed on a grate in the horizontal plane to absorb excessive moisture in the air. This regulates humidity and affects the dry-bulb temperature. 4 A series of permanently open ventilation slots in the ground gain from the hot external air, but still allow cooling through air changes from the cool basement. To determine the airflow rates induced through the system by buoyancy at maximum cooling conditions with the surface temperature in the labyrinth at 12C a series of steady-state simulations were carried out for a range of external temperatures. In these cases the chimneys are not glazed, so there is negligible solar assistance. These results show that system performance varies with external temperature (Table 1). At 17.5C, the flow rate is approximately 6ACH (1,200l/s). The flow rate decreases as the ambient temperature approaches 20C, then slowly begins to slowly increase again as external temperatures head towards 30C. For this set of conditions, the required flow rate cannot be achieved without some form of assistance for ambient temperatures between 17.5C and 30C. This could be by running fans, but buoyancy forces can be increased by introducing heat into the chimneys above the occupied space. This could be achieved by using high G value, low U value glazing in the simulations, a computer model has been constructed to predict the performance of the laboratory for a typical UK year. The simulation assumes that a single laboratory module is operating for nine hours per day for a fiveday working week. Under daytime operating conditions, the fan-assisted system draws air through the labyrinth and into the laboratory. Under winter conditions, the incoming air is heated so that it enters the supply grilles at 18.5C to maintain temperature in the laboratory. To cool the labyrinth in summer conditions and, to a much lesser extent, warm it in winter air is drawn through the labyrinth during unoccupied periods. The model was run for typical south-east England conditions, with a minimum temperature of -3.6C and a summer maximum of 30.8C. On this basis, the proposed system provides the following performance: Hours below 22C: 0 Hours above 24C: 59 Hours above 25C: 20 Hours above 26C: 3 Hours above 27C: 0 Although the heating is only operated floor (10-15% of floor area) allow cool air to rise into the laboratory zone at ground floor level. 5 The laboratory zone is kept cool or warm by the air rising from the basement. The laboratory zone windows at ground floor level are not openable, as this would compromise the stack effect, air cleanliness and humidity. 6 The laboratory zone opens into three solar-gain chimneys. These are sized to enable the stack effect and extract warm air from the laboratory through openable vents. They are glazed to increase solar gain and the stack effect. 7 Apertures can be adjusted to control the volume of airflow, depending on the time, season or weather. In this way, the temperature within the laboratory zone is regulated. Ambient (C) Floor (C) Flow rate (l/s) Room (C) 30.0 14.3 1,017 23.2 25.0 14.0 977 23.3 22.5 14.2 914 24.1 20.0 17.6 905 27.6 17.5 18.5 1,236 25.9 Table 1: Induced flows no solar assistance 12C labyrinth temperature OTHER EXAMPLES There are other examples of similar and successful labyrinth stack-effect designs, which while more generic in application and less focused than a laboratory module are worth noting. Also worthy of mention is a laboratory-specific Figure 3: Long section flow simulation evaporative cooling downdraught design, cited below. 1. AVCI Architects with Atelier 10 Turkish Contractors Association HQ , Ankara, Turkey 2013 2. Short Associates Lanchester Library, University of Coventry 1999 3. Nimish Patel & Parul Zaveri Torrent Research Laboratories, Ahmedabad, India 1997 Figure 4: Long section temperature summer simulation chimneys to maximise solar gains. These results show that, with modest solar assistance, the flow through the system can be boosted to 6ACH or greater (Table 2).This will further decrease the number of hours it will be necessary to run the fans. Computational fluid dynamics (CFD) simulations were also carried out with fans in operation. These were used to calculate a heat transfer coefficient for the labyrinth system, for use in the annual performance calculation. Annual performance It has been established that the labyrinth potentially provides adequate cooling to maintain laboratory conditions under steady-state conditions. To maintain an adequate airflow, fan assistance will be required for a proportion of the year. Using data derived from the CFD Ambient (C) Floor (C) Flow rate (l/s) Room (C) 30.0 14.2 1,124 22.2 25.0 14.7 1,364 21.4 20.0 18.0 1,347 24.7 Table 2: Induced flows 1.1kW solar per chimney 12oC labyrinth temperature (if necessary) during laboratory operating hours, the total heating demand for the year is predicted as 22,300kWh. This value is because of the requirement to supply 6ACH of tempered fresh air to the space. eadE RMOR OTHER EXAMPLES Possible improvements The shape volume and form of the module is critical to its satisfactory performance. For instance, Figures 3 and 4 show the central stack to be slightly undersized and some stagnation in the central labyrinth area. The validation exercise also identified the need for sufficient heat gains in the chimneys to drive the stack effect. As a result, the part use of extract fans in the validation exercise could be eliminated. The introduction of GSHPs to the labyrinth would effectively provide a temperate supply zone yearround, and reduce the winter basement heat demand consumption. Further development of the model with GSHPs in the basement for heating and cooling could make the model suited to less temperate climates. Conclusion This validation exercise confirms the initial idea of the naturally ventilated displacement ventilation model. Optimum form volume and shape are key, as is the careful control of temperature differences between external ambient, labyrinth and chimney to generate the required stack effect. As a new method of ventilating a laboratory, it poses a deliverable risk to a client, though the financial risk may be passed on to the consultant or contractor consortium responsible for the design and construction. As a way of addressing these concerns, a smallscale prototype may be considered. CJ MARK JANK is major projects manager at Brunel University London and previously worked at the University of East London