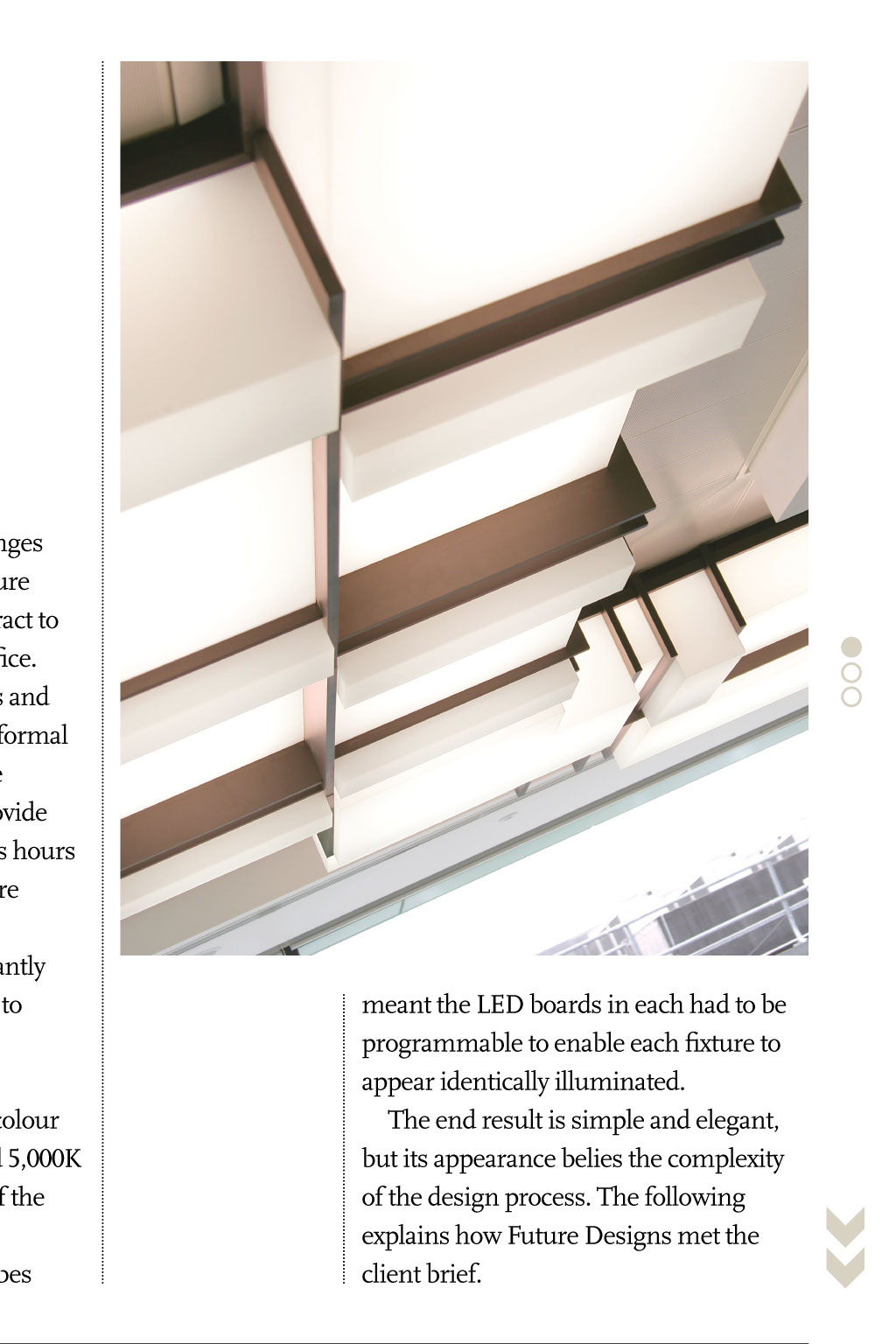

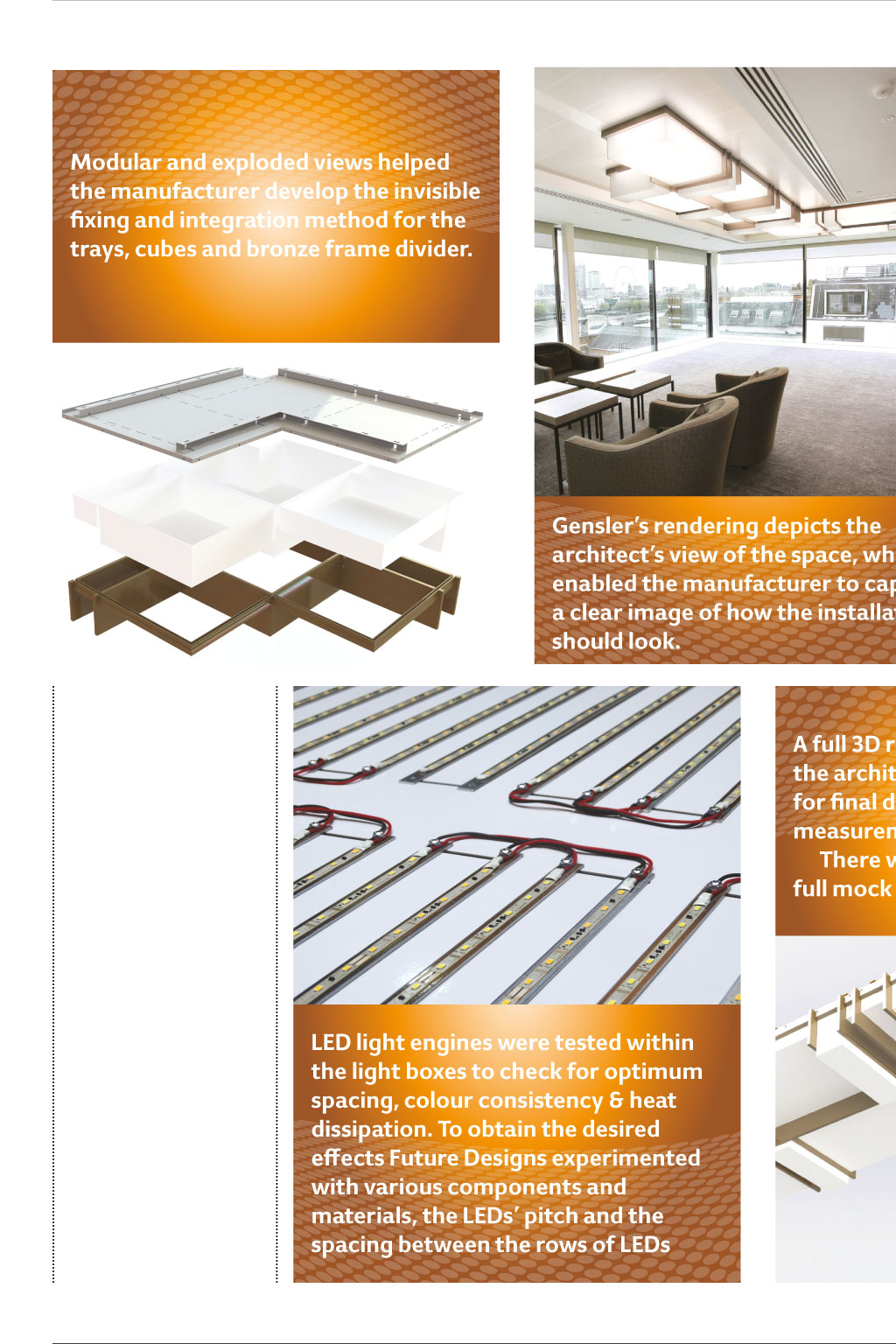

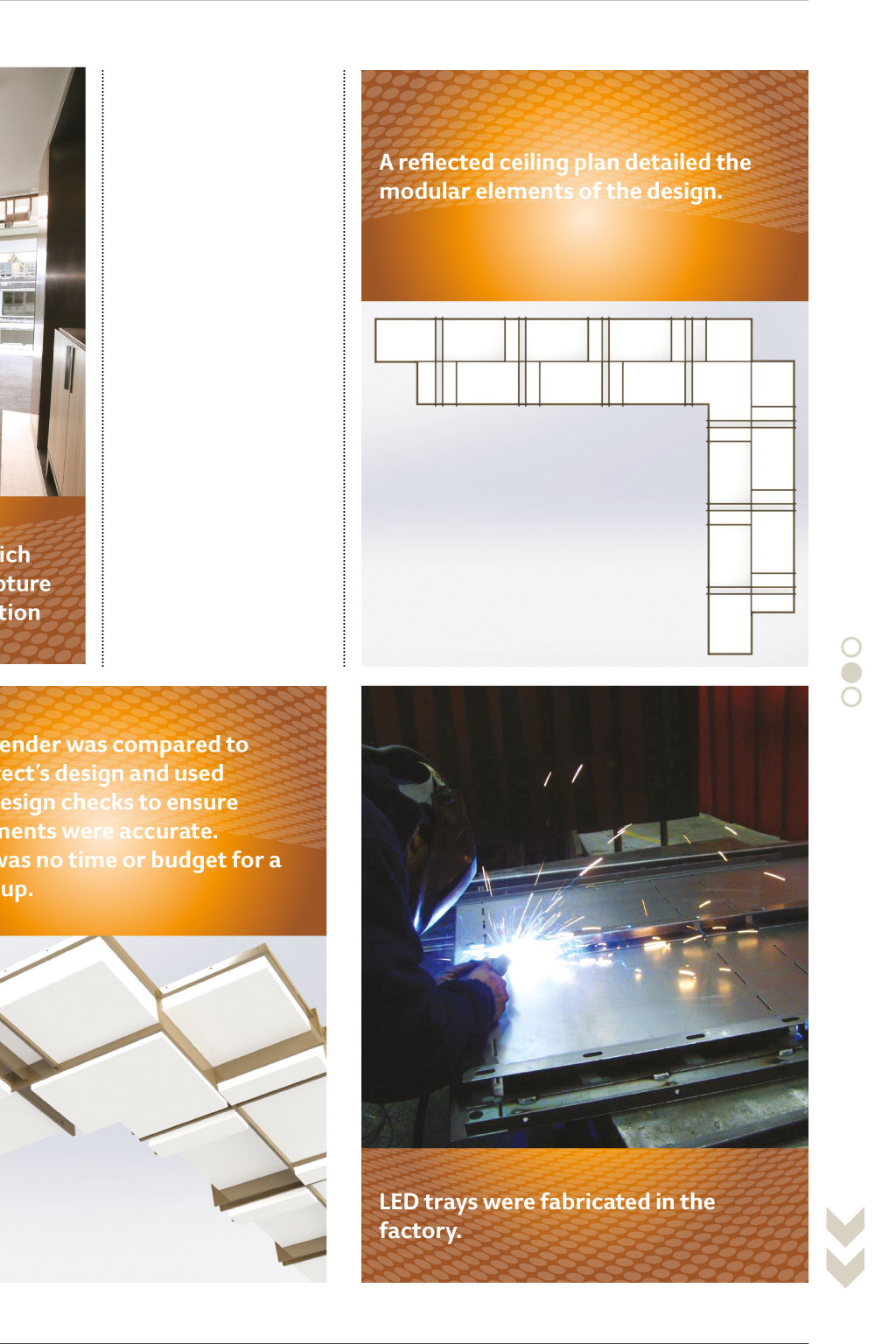

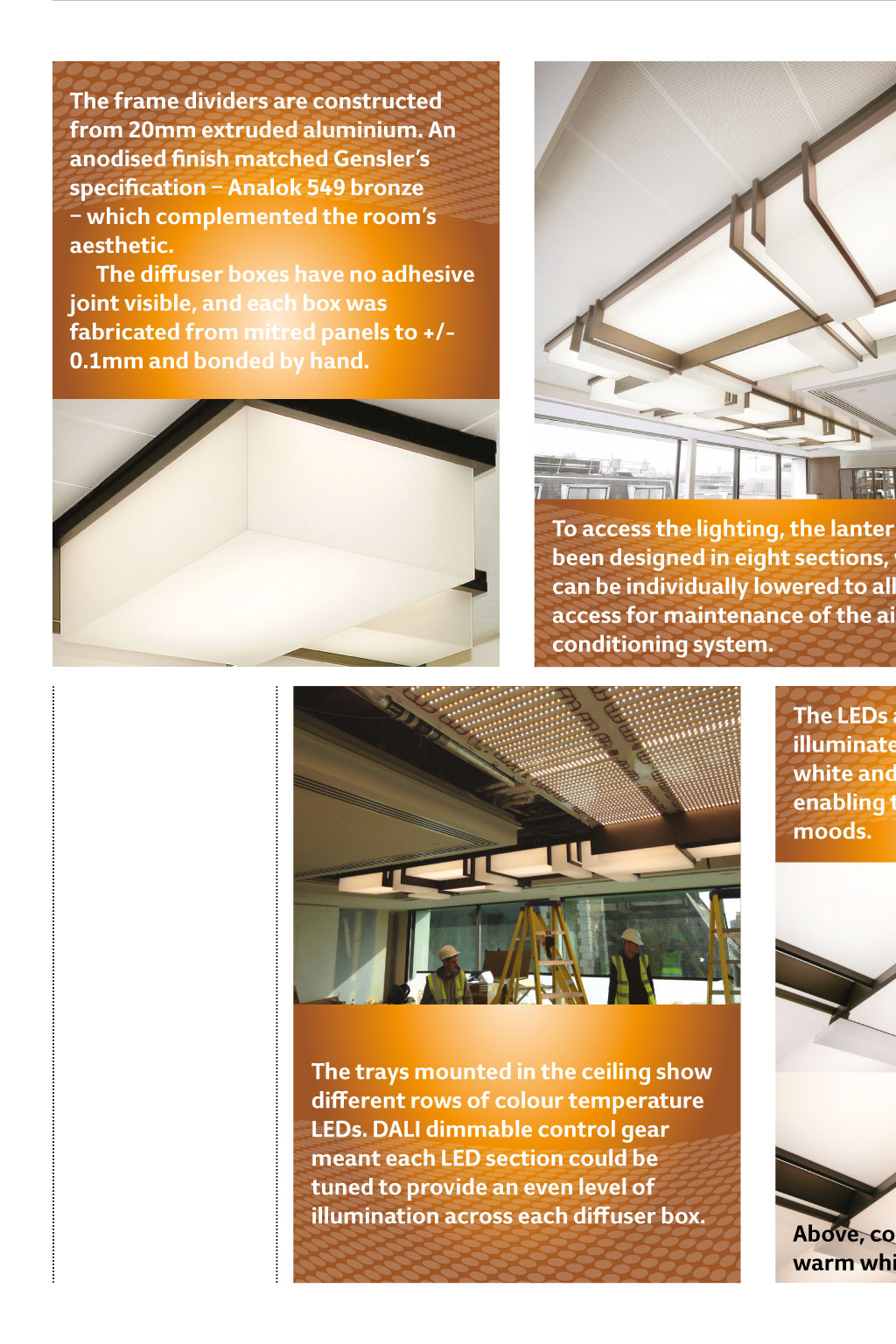

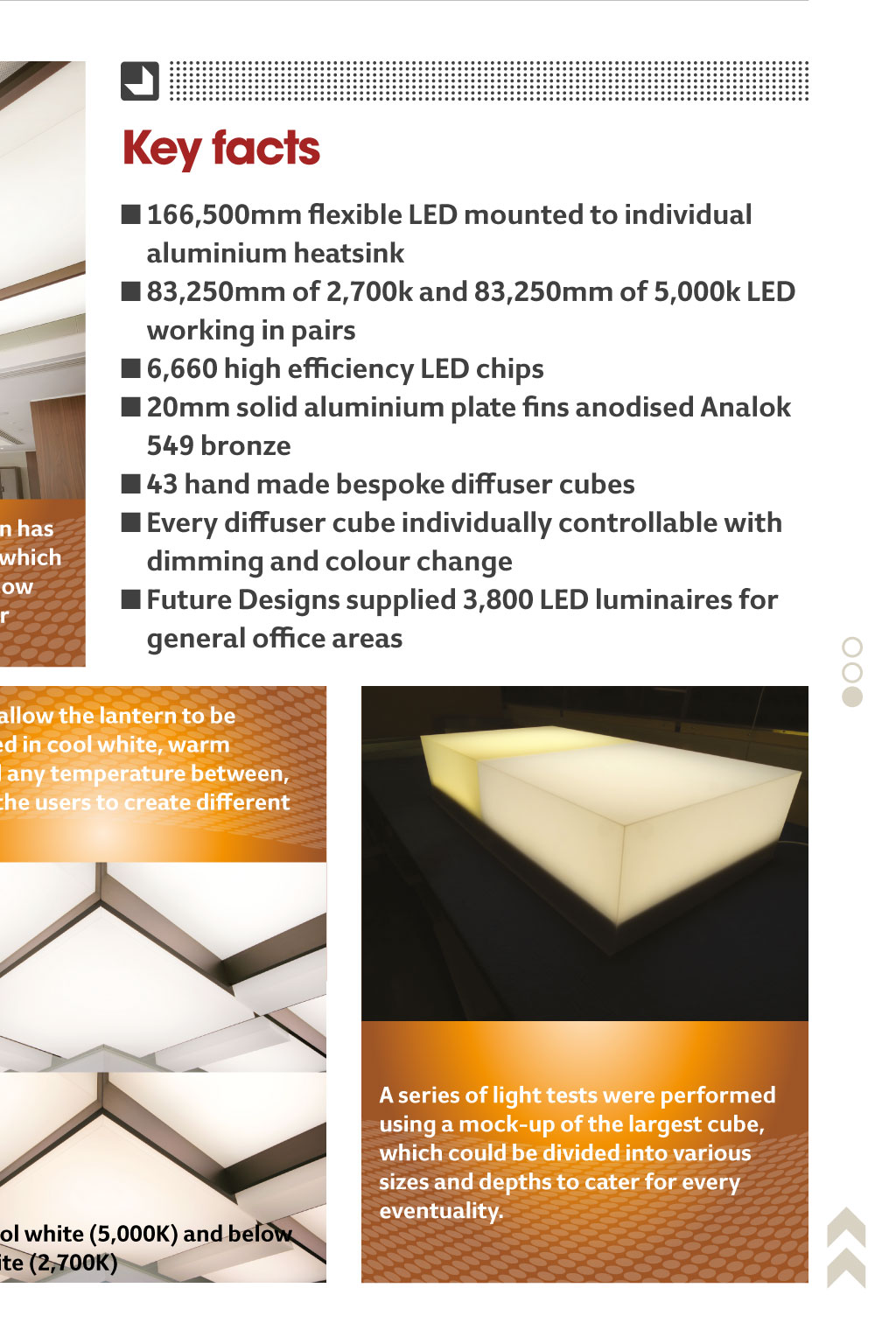

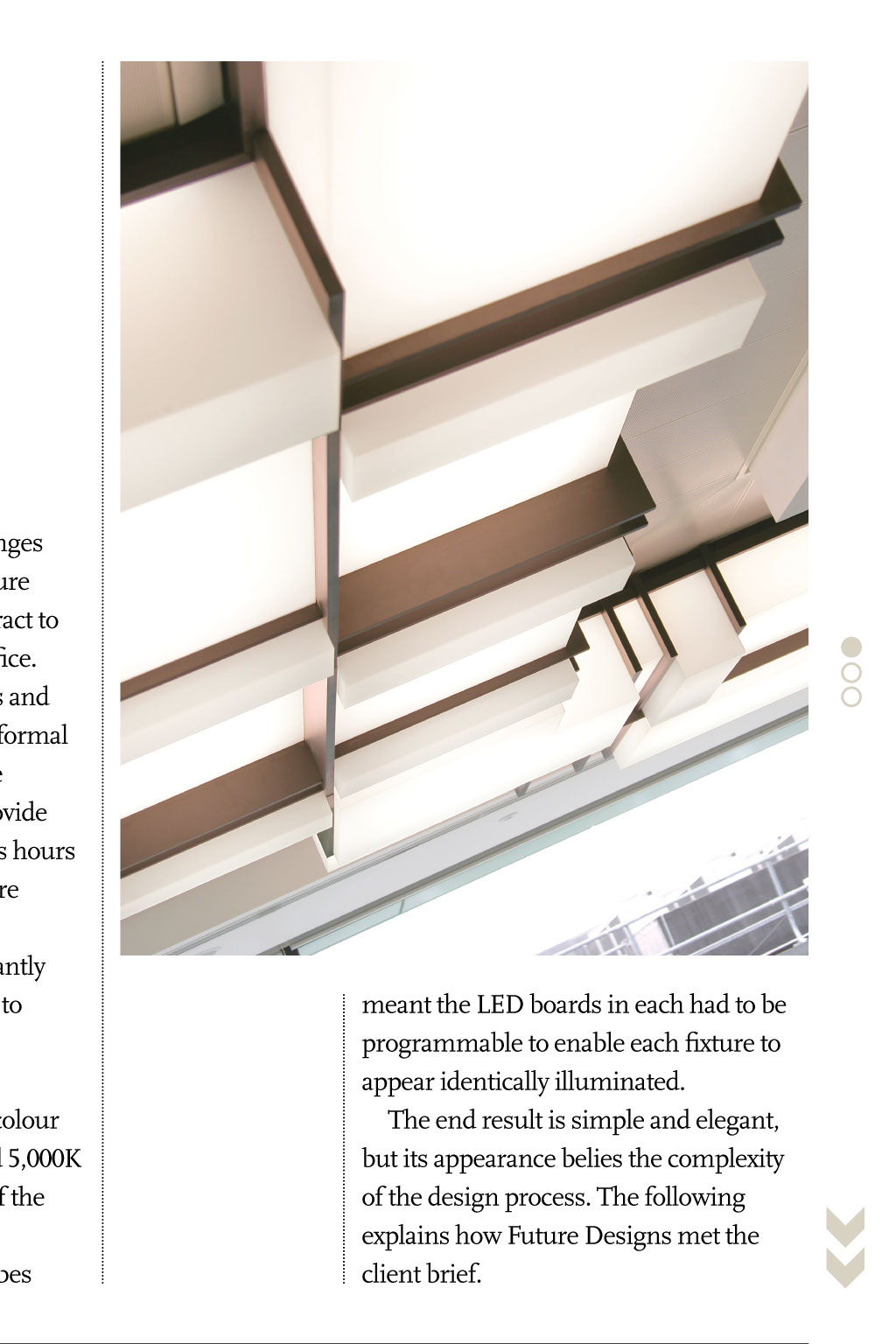

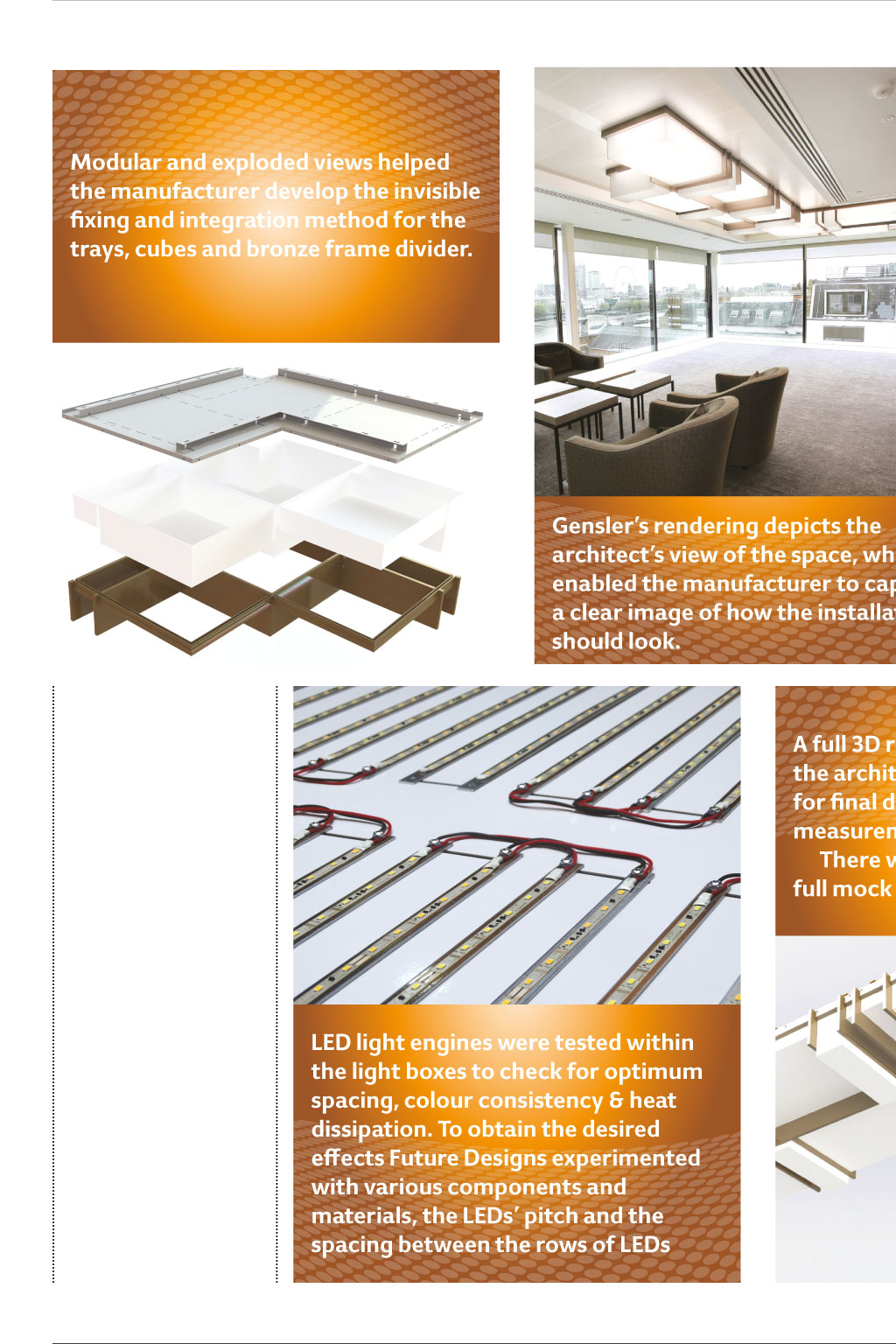

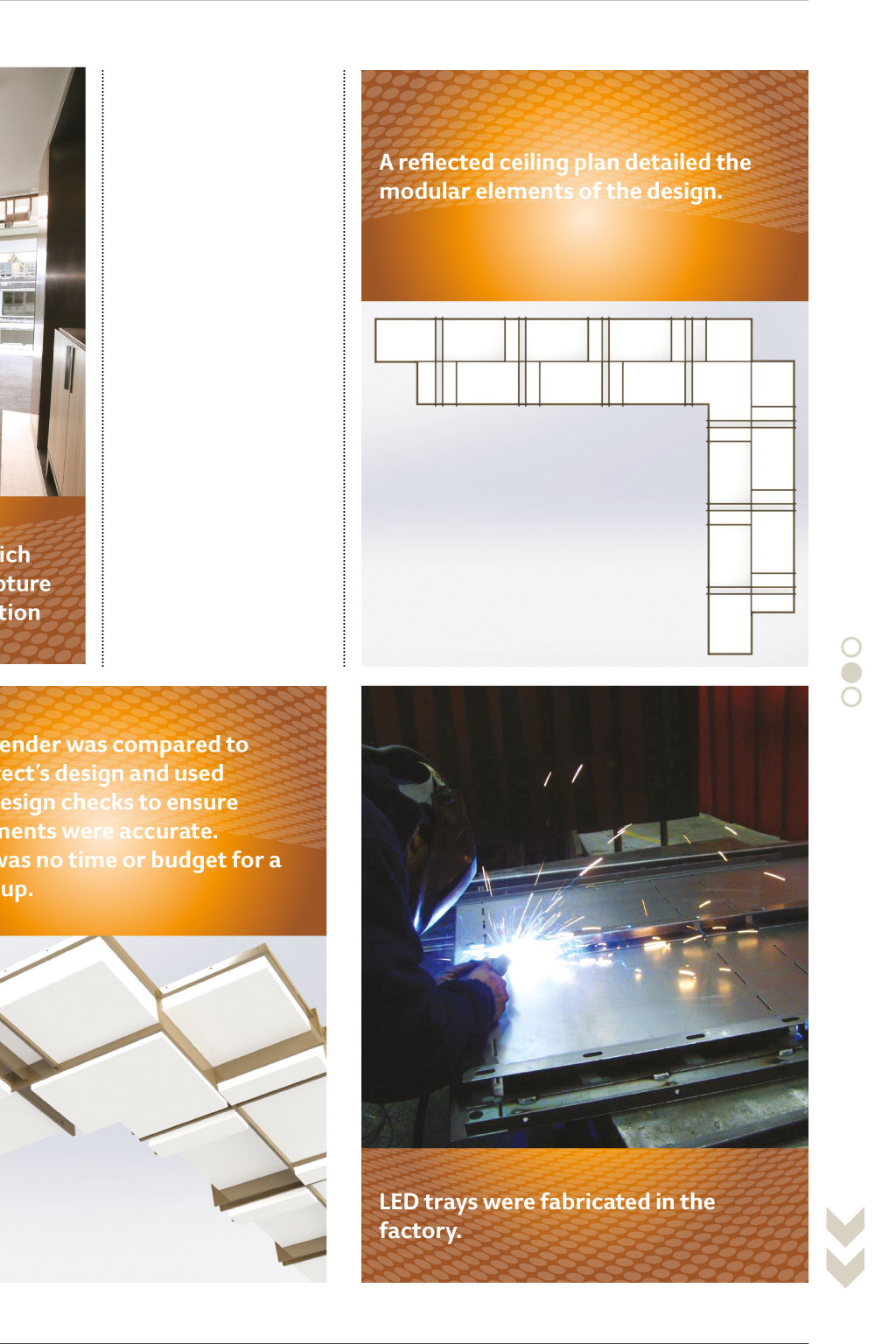

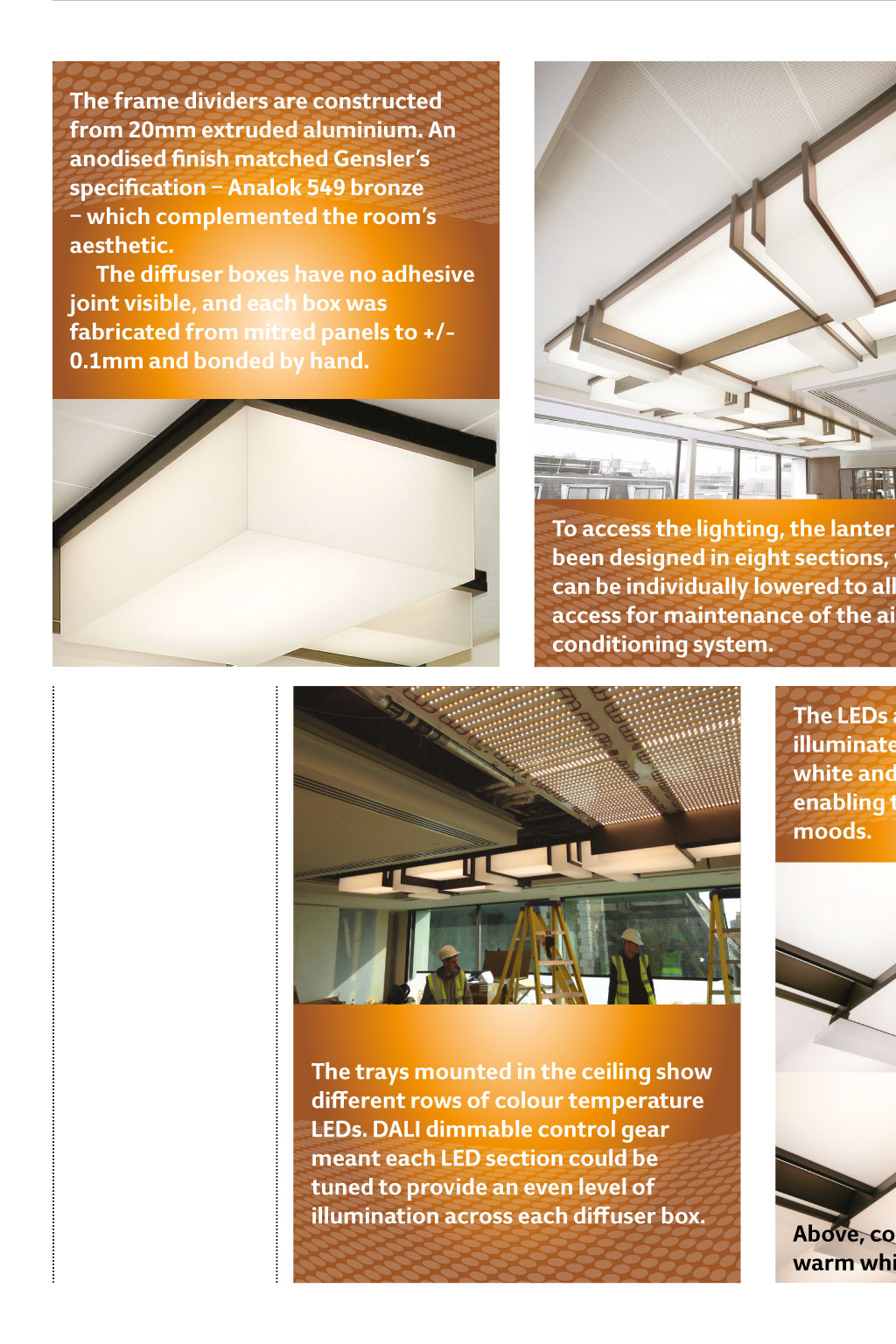

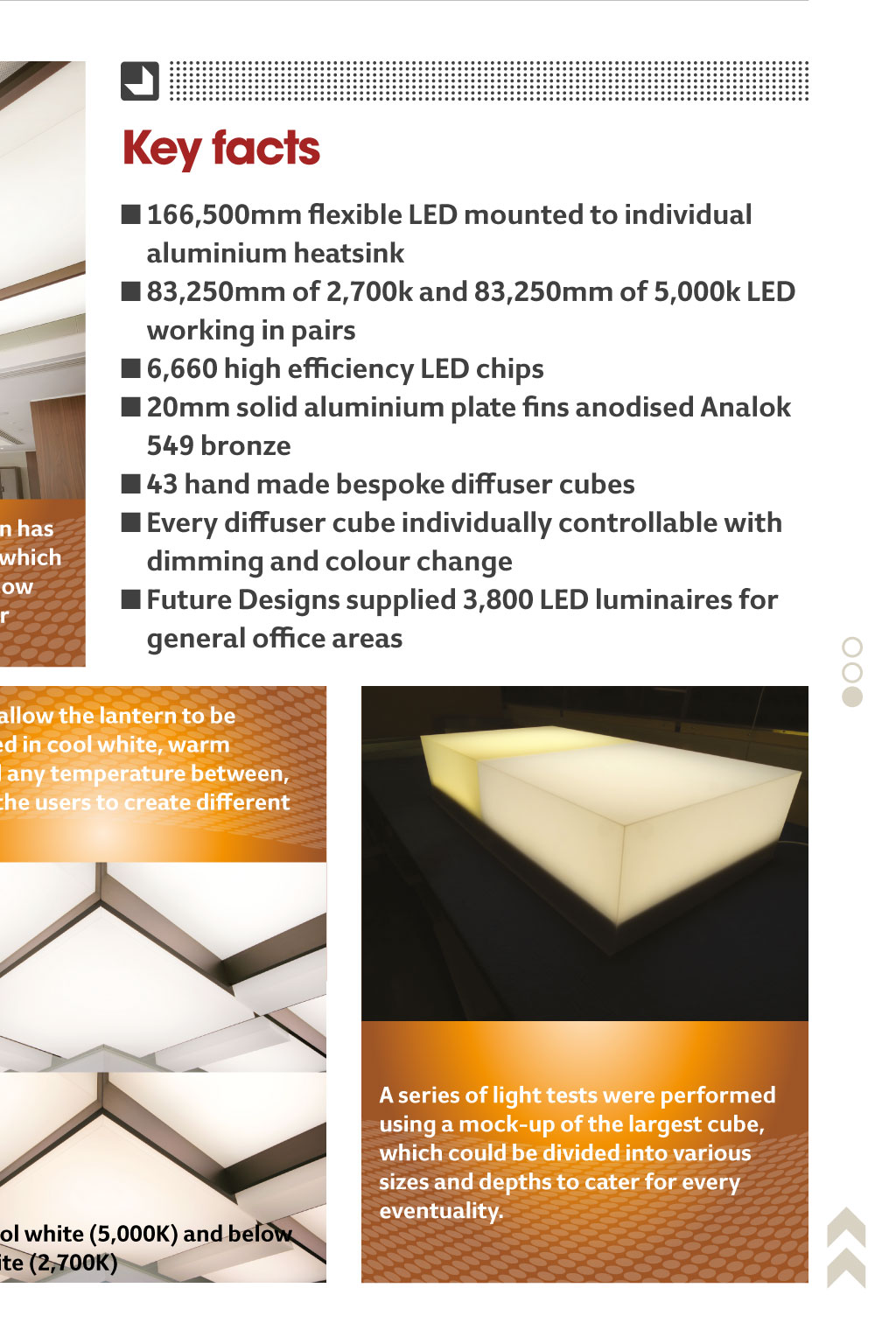

LIGHTING DESIGN BANK LUMINAIRE Bank of LIGHTS An interlocking cuboid lantern forms the centerpiece of an entertainment suite at a prestigious global bank. Alex Smith pieces together the design puzzle A room named after the founder of a prestigious global bank was bound to impress, with floor-toceiling glazing to the south and west sides of the corner room on Victoria Embankment offering City financiers sweeping views of the Thames. In the interior, the visitors attention is drawn upwards to a jigsaw of diffuser boxes attached to the ceiling of the L-shaped space. These cuboids of varying sizes and depths are bound together by a fine bronze trim and backplate, and make up the 6.1m x 4.8m lantern that provides lighting to the room. The design by architect Gensler looks simple and elegant it bears a resemblance to one of Charles Rennie Macintoshs rectilinear designs but its appearance posed some challenges for the lighting manufacturer Future Designs, which had won the contract to replace lighting in this London office. The room hosts client meetings and presentations during the day and formal dining and corporate events in the evening. The luminaire had to provide even illumination during business hours and a warmer atmosphere for more informal events in the evening. With the natural daylight constantly changing, the lanterns cubes had to be adjustable to maintain an even distribution of light. Every box is dimmable and glows at different colour temperatures between 2,700K and 5,000K depending on the requirements of the users and the daylight levels. The varying geometry of the cubes meant the LED boards in each had to be programmable to enable each fixture to appear identically illuminated. The end result is simple and elegant, but its appearance belies the complexity of the design process. The following explains how Future Designs met the client brief. Modular and exploded views helped the manufacturer develop the invisible fixing and integration method for the trays, cubes and bronze frame divider. A reflected ceiling plan detailed the modular elements of the design. Genslers rendering depicts the architects view of the space, which enabled the manufacturer to capture a clear image of how the installation should look. A full 3D render was compared to the architects design and used for final design checks to ensure measurements were accurate. There was no time or budget for a full mock up. LED light engines were tested within the light boxes to check for optimum spacing, colour consistency & heat dissipation. To obtain the desired effects Future Designs experimented with various components and materials, the LEDs pitch and the spacing between the rows of LEDs LED trays were fabricated in the factory. The frame dividers are constructed from 20mm extruded aluminium. An anodised finish matched Genslers specification Analok 549 bronze which complemented the rooms aesthetic. The diffuser boxes have no adhesive joint visible, and each box was fabricated from mitred panels to +/0.1mm and bonded by hand. Key facts To access the lighting, the lantern has been designed in eight sections, which can be individually lowered to allow access for maintenance of the air conditioning system. 166,500mm flexible LED mounted to individual aluminium heatsink 83,250mm of 2,700k and 83,250mm of 5,000k LED working in pairs 6,660 high efficiency LED chips 20mm solid aluminium plate fins anodised Analok 549 bronze 43 hand made bespoke diffuser cubes Every diffuser cube individually controllable with dimming and colour change Future Designs supplied 3,800 LED luminaires for general office areas The LEDs allow the lantern to be illuminated in cool white, warm white and any temperature between, enabling the users to create different moods. The trays mounted in the ceiling show different rows of colour temperature LEDs. DALI dimmable control gear meant each LED section could be tuned to provide an even level of illumination across each diffuser box. Above, cool white (5,000K) and below warm white (2,700K) A series of light tests were performed using a mock-up of the largest cube, which could be divided into various sizes and depths to cater for every eventuality.