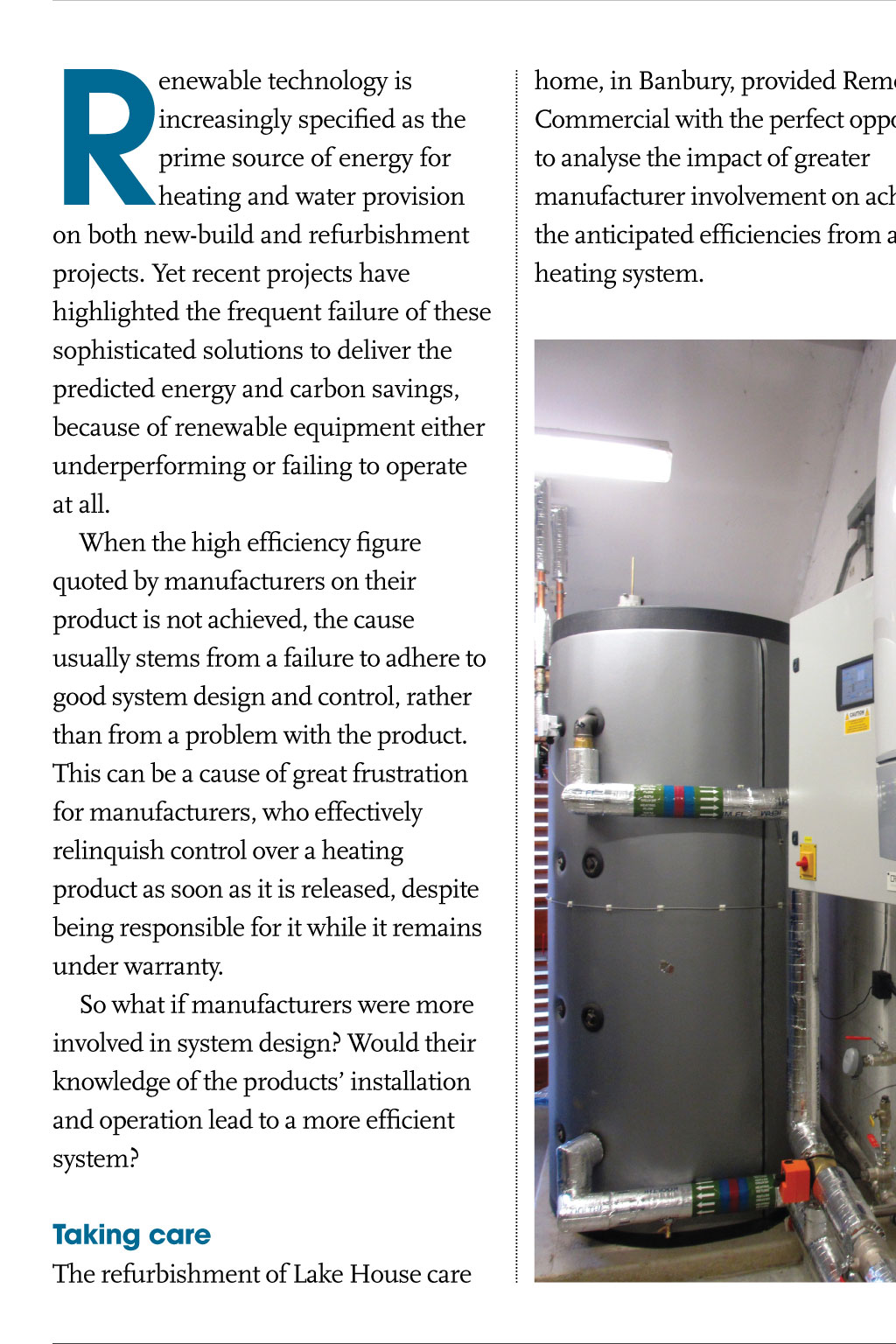

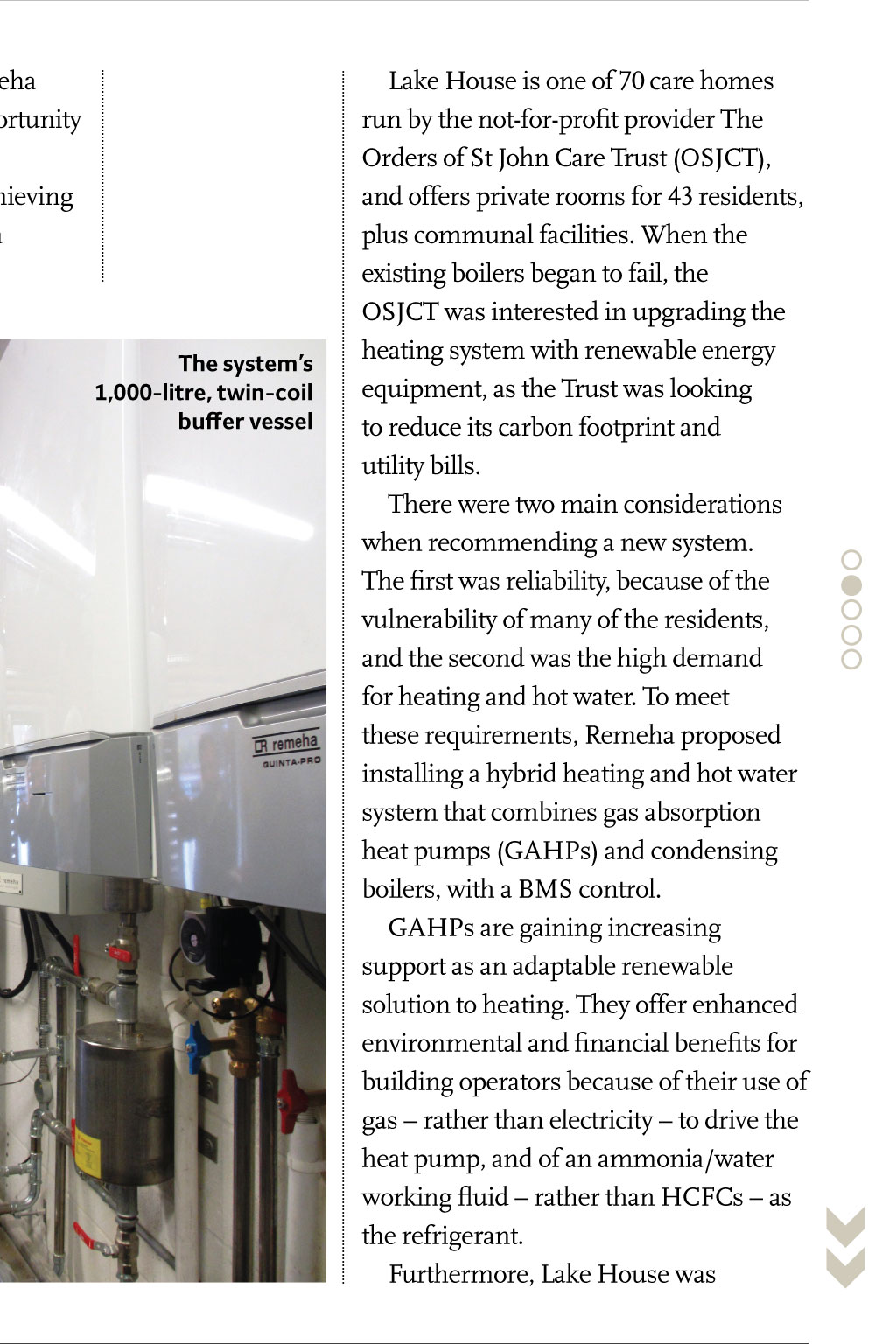

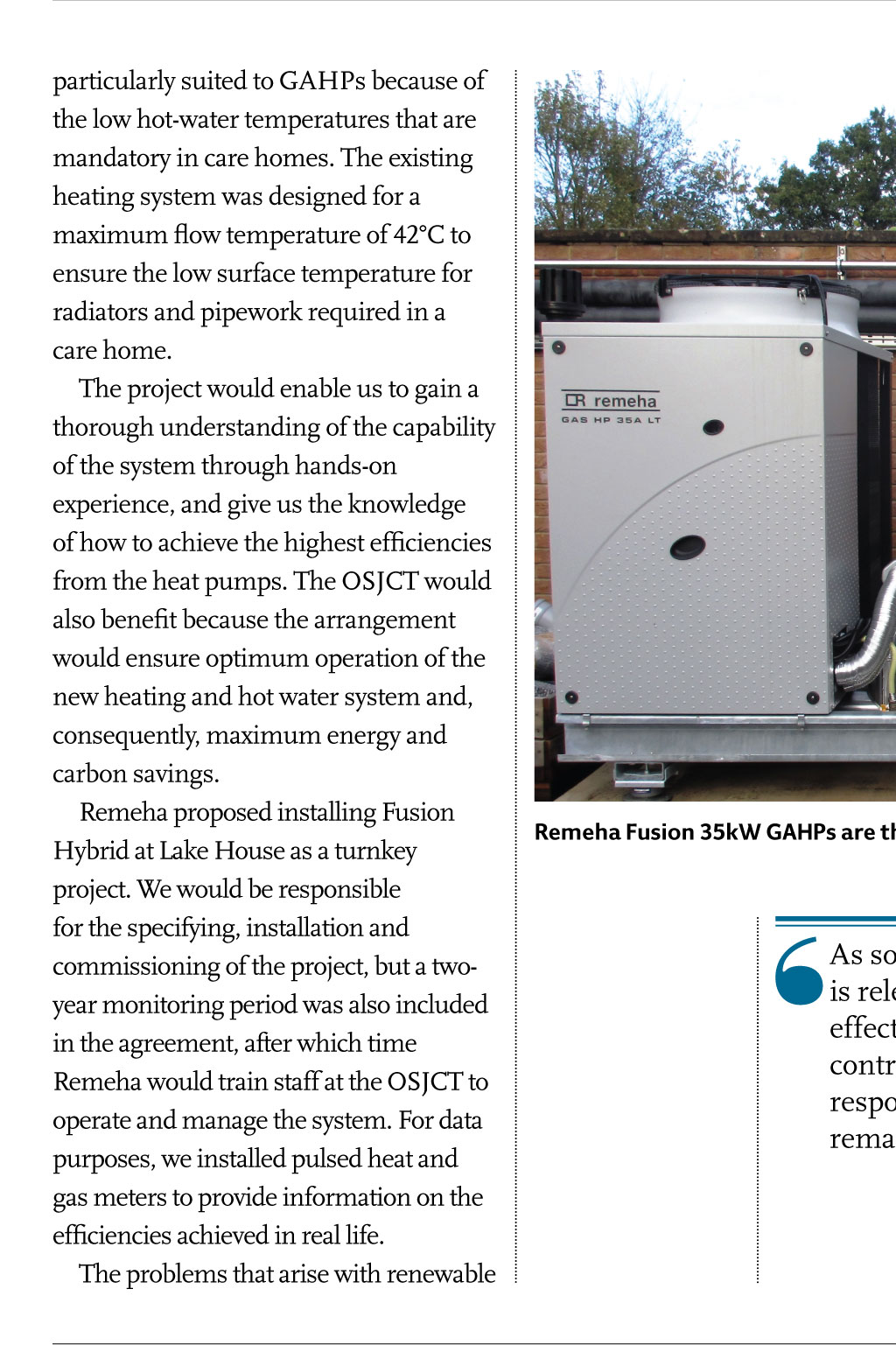

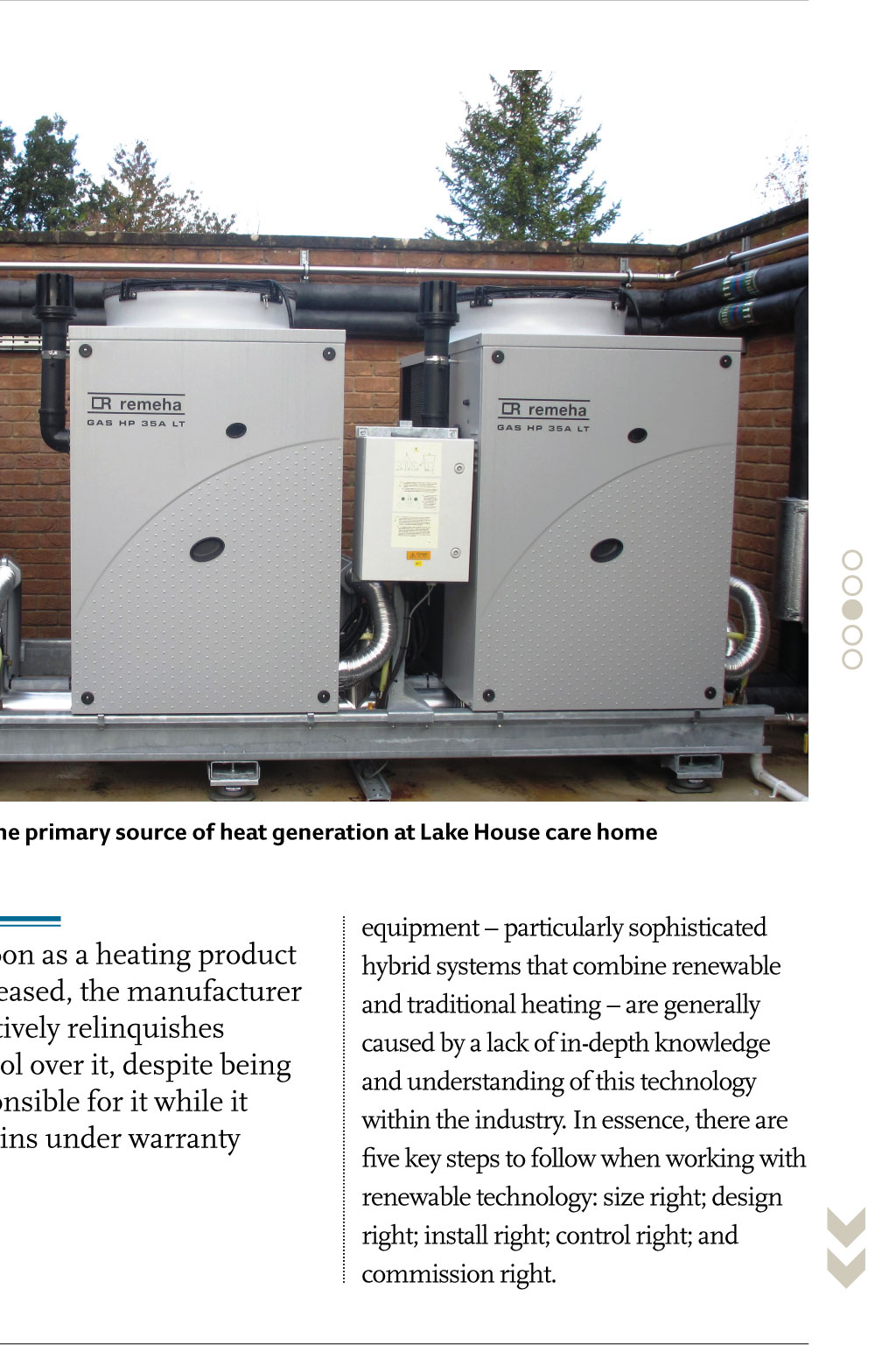

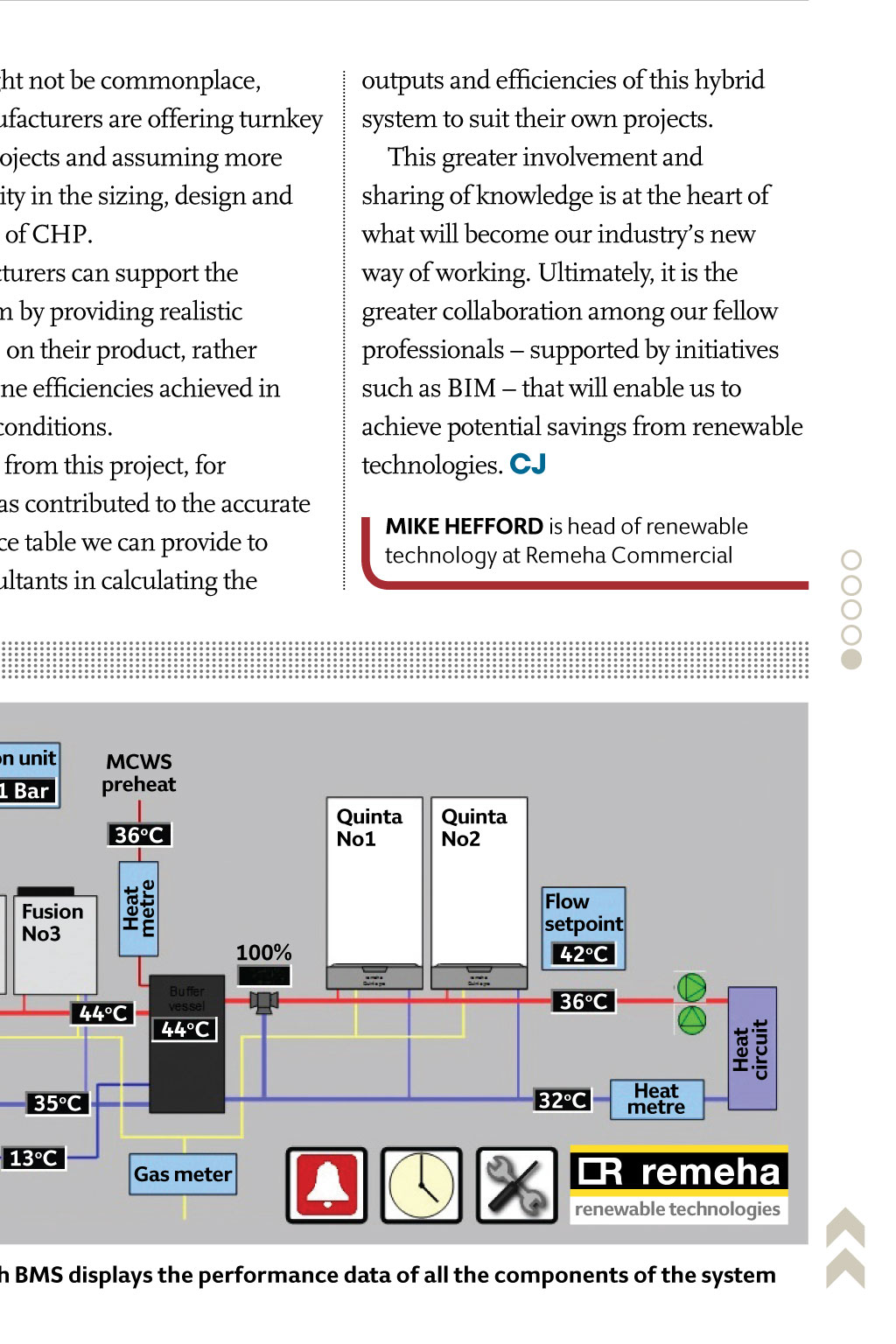

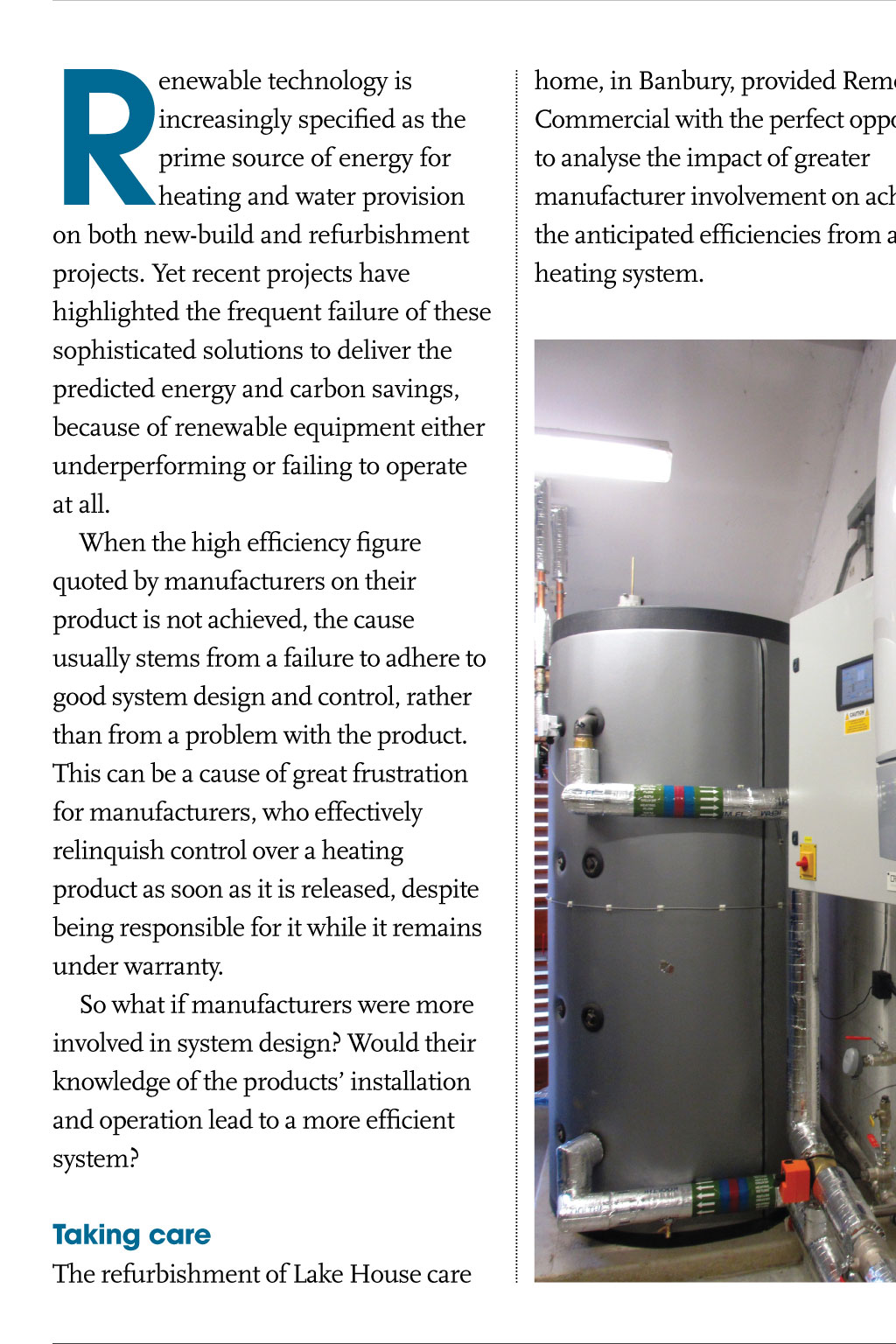

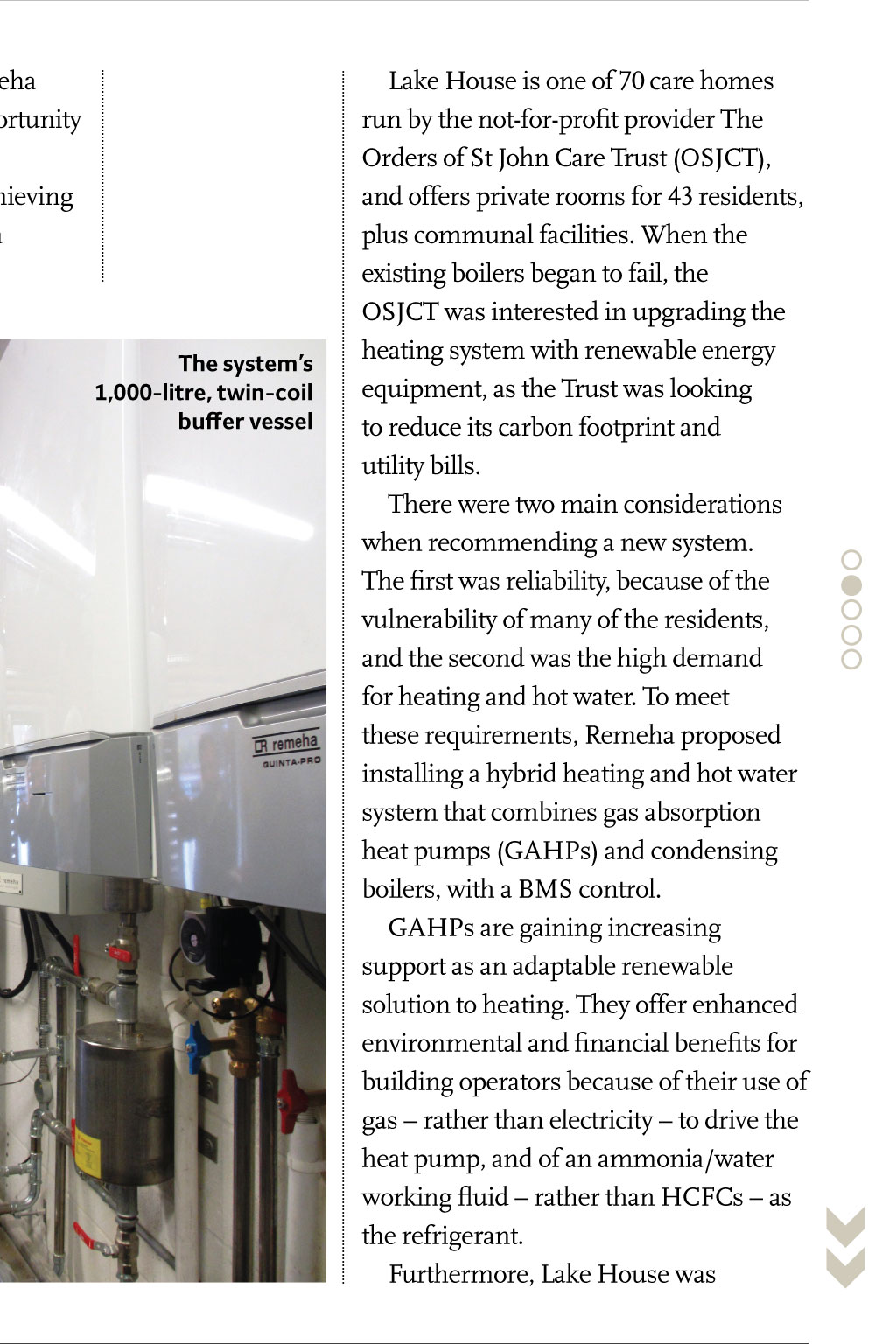

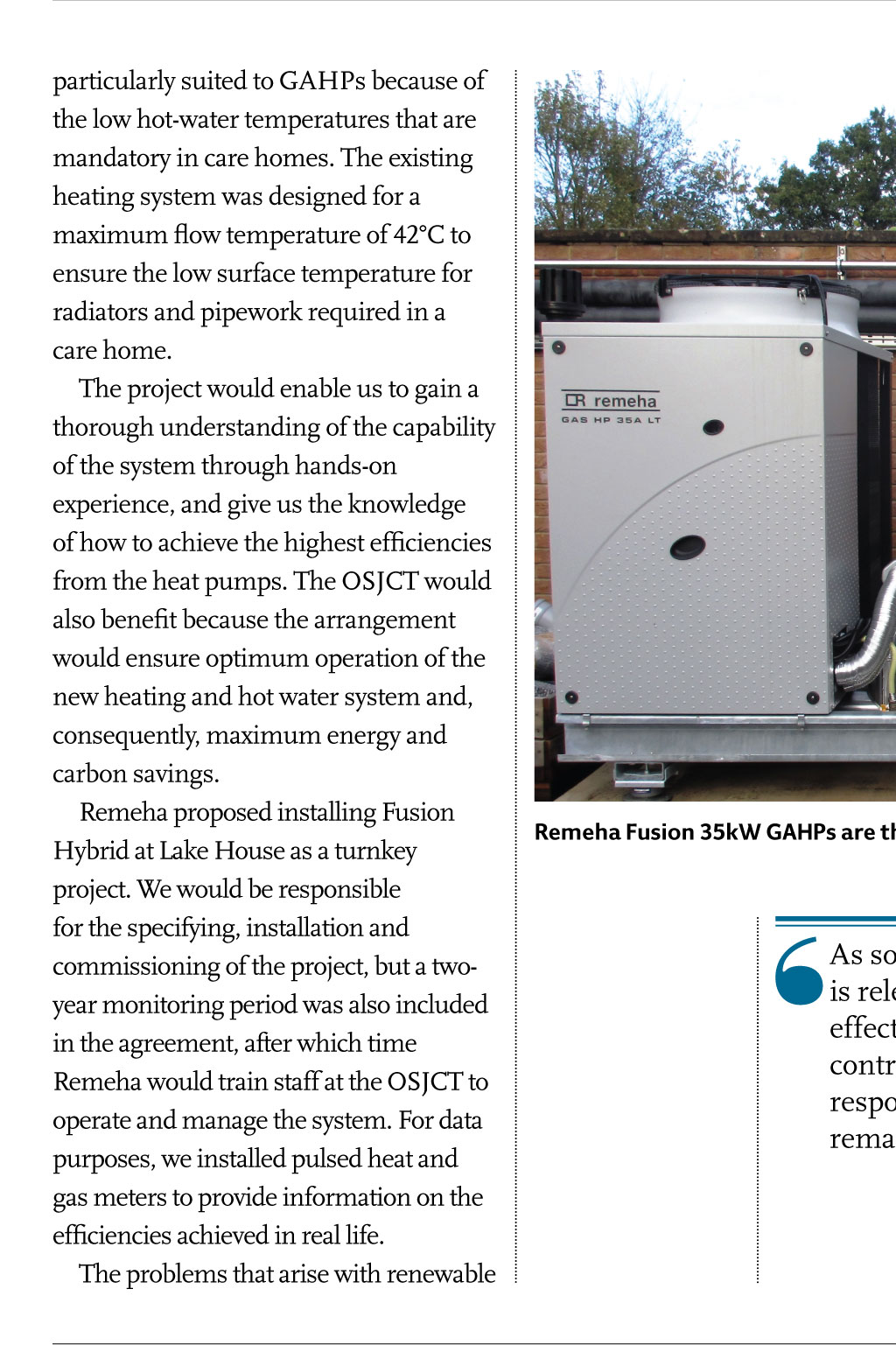

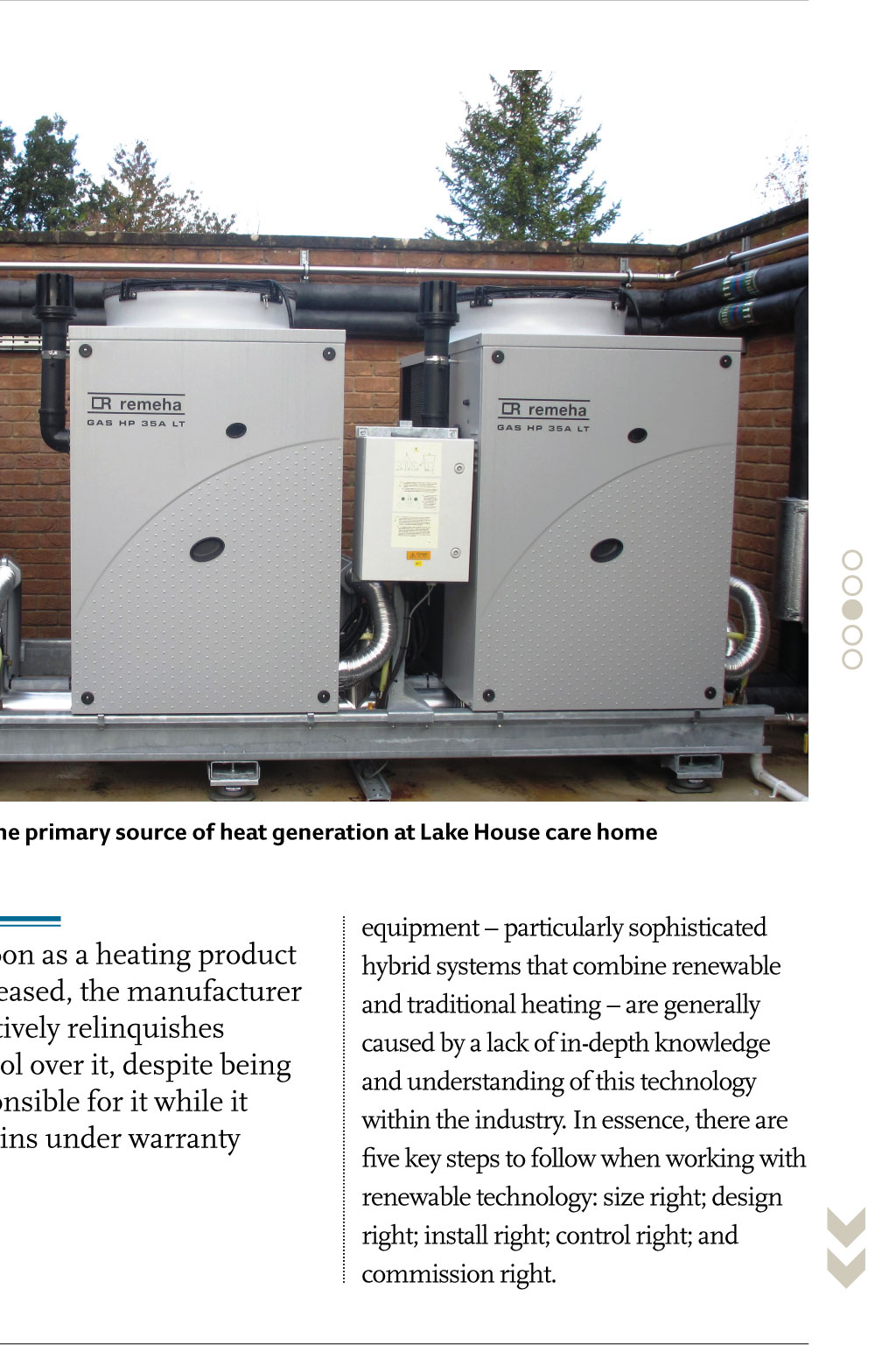

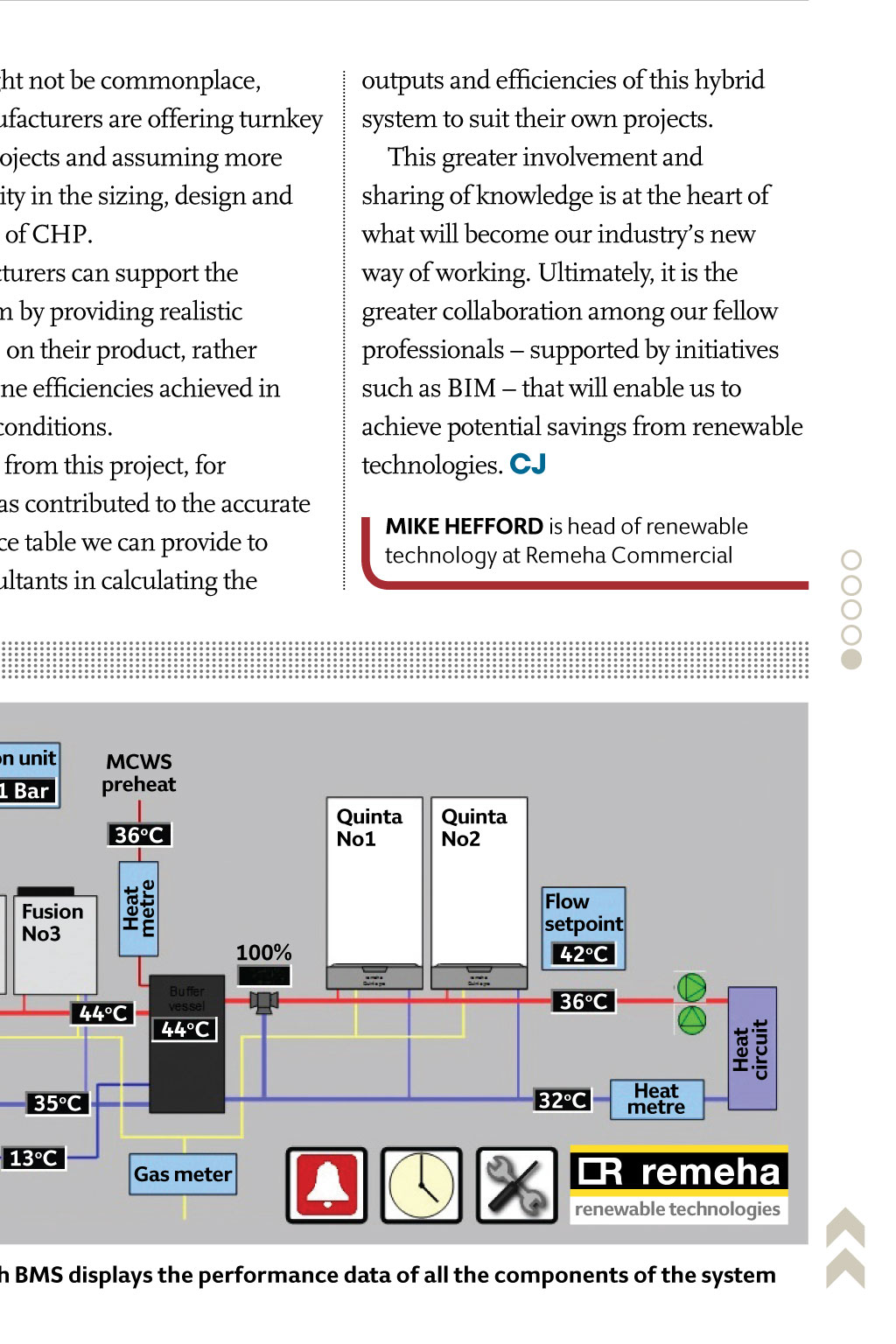

cARe hoMe hEaT puMps AfteRcARe seRVice As industry debates the level of involvement required from manufacturers to raise efficiencies, Remeha Commercials Mike Hefford provides an insight into a two-year project where the firm was responsible for the design, installation and monitoring of heat pumps in a hybrid heating and hot water system for a care home near Banbury home, in Banbury, provided Remeha Commercial with the perfect opportunity to analyse the impact of greater manufacturer involvement on achieving the anticipated efficiencies from a heating system. the systems 1,000-litre, twin-coil buffer vessel taking care The refurbishment of Lake House care care-home package The care home was previously heated by three condensing boilers with a total output of 180kW. To meet the required heating and hot-water demand, three 35kW GAHPs were installed on a plinth in a yard outside the boiler house, as the primary source of heat generation. The GAHPs directly heat water within a 1,000-litre, twin-coil buffer vessel to 50C and preheat the cold water feed. Heat is transferred to the heating system by a coil in the cylinder and blended with the return water to reach the required flow temperature. This is controlled according to heat load and can be as low as 30C. The lead heat pump is rotated every 200 hours to ensure good operation. The system also includes two 45kW gas condensing boilers, installed in cascade to provide support when required although, to date, the need for them has been minimal because of the output of the GAHPs. In addition, the GAHPs are used to preheat incoming mains water before it is reheated by direct-fired water heaters with an output of 48kW. A seven-inch touchscreen panel was designed to ensure easy operation of the system (see panel, In control). The transition to the new system was remeha Fusion 35kW GaHPs are the primary source of heat generation at Lake House care home As soon as a heating product is released, the manufacturer effectively relinquishes control over it, despite being responsible for it while it remains under warranty Lessons learned The project has demonstrated the enormous energy-saving potential of gas absorption heat pumps. Before the Lake House experience, we had anticipated achieving efficiencies of between 120% and 130%; this proved to be a conservative estimate because data from the pulsed gas and heat meters indicates that the GAHPs are delivering a seasonal efficiency of 140% net (126% gross). Manufacturers can support the project team by providing realistic efficiencies on their product, rather than headline ones achieved in a laboratory few minor tweaks required to the controls for the gas absorption heat pumps. This project has confirmed to us the value of consulting manufacturers on hybrid and renewable technology to achieve maximum thermal efficiencies. The detailed product information that manufacturers hold from how it works to how best to size it, combine it with other equipment and integrate it into an existing system can be critical in avoiding an energy performance gap from heating. While the monitoring process at Lake in control Good control is critical to the effective operation of hybrid systems, enabling individual components and the overall system to achieve their maximum potential. Our system uses a specially configured, scalable BMS to integrate the two high-efficiency technologies, and more accurately to match the heating and hot-water requirements of the building. It is important that controls are straightforward and easy to use. With our system, a seven-inch touch-screen panel displays the performance data of all the components, with clear options for adjustments to ensure optimum operational efficiencies. It can also be monitored and controlled remotely. House might not be commonplace, more manufacturers are offering turnkey biomass projects and assuming more responsibility in the sizing, design and installation of CHP. Manufacturers can support the project team by providing realistic efficiencies on their product, rather than headline efficiencies achieved in laboratory conditions. The data from this project, for example, has contributed to the accurate performance table we can provide to assist consultants in calculating the Pressurisation unit Ok 1.1 Bar Fusion no3 100% 44 C o Flow setpoint 42oC 44oC 32oC 35 C 13oC Quinta no2 36oC o Cold water in Mike HeFFOrD is head of renewable technology at Remeha Commercial Quinta no1 36 C Fusion no2 outputs and efficiencies of this hybrid system to suit their own projects. This greater involvement and sharing of knowledge is at the heart of what will become our industrys new way of working. Ultimately, it is the greater collaboration among our fellow professionals supported by initiatives such as BIM that will enable us to achieve potential savings from renewable technologies. cJ MCWS preheat o Fusion no1 equipment particularly sophisticated hybrid systems that combine renewable and traditional heating are generally caused by a lack of in-depth knowledge and understanding of this technology within the industry. In essence, there are five key steps to follow when working with renewable technology: size right; design right; install right; control right; and commission right. The heat pumps are also providing around 90-95% of the heating for the care home. In terms of savings, a comparison of energy use from December 2013 and December 2014 reveals a 27% reduction in gas consumption after the installation of the system. We would expect the heat pump to last between 15 and 18 years, and with the heat pump running around 40% more efficiently, the financial payback for the OSJCT is four to five years or sooner still when gas-driven heat pumps become eligible for Renewable Heat Initiative (RHI) funding. Ideally, there would have been an allocation in the budget to upgrade the water heaters. Zoned control was also not an option. That said, the occupancy at Lake House stays fairly stable because it is a care home, and the extra valves and pumps that zoned control requires would have brought higher capital and running costs for the nursing facility. We carried out careful commissioning, because this step is crucial to achieving maximum performance, and yet is often the part that is skimped on when projects run over budget. The hydraulic commissioning confirmed that everything was working well, with just a carried out in just half a day, with the two condensing boilers installed first, in order to maintain heating and hot water throughout the care home. GAHP maintenance needs are similar to those of condensing boilers. The gas generator is serviced in the same way, and unless theres a failure no scheduled maintenance is needed on the refrigeration circuit over its life. The toothed belt for the internal pump has to be replaced every three to four years. Heat metre particularly suited to GAHPs because of the low hot-water temperatures that are mandatory in care homes. The existing heating system was designed for a maximum flow temperature of 42C to ensure the low surface temperature for radiators and pipework required in a care home. The project would enable us to gain a thorough understanding of the capability of the system through hands-on experience, and give us the knowledge of how to achieve the highest efficiencies from the heat pumps. The OSJCT would also benefit because the arrangement would ensure optimum operation of the new heating and hot water system and, consequently, maximum energy and carbon savings. Remeha proposed installing Fusion Hybrid at Lake House as a turnkey project. We would be responsible for the specifying, installation and commissioning of the project, but a twoyear monitoring period was also included in the agreement, after which time Remeha would train staff at the OSJCT to operate and manage the system. For data purposes, we installed pulsed heat and gas meters to provide information on the efficiencies achieved in real life. The problems that arise with renewable Lake House is one of 70 care homes run by the not-for-profit provider The Orders of St John Care Trust (OSJCT), and offers private rooms for 43 residents, plus communal facilities. When the existing boilers began to fail, the OSJCT was interested in upgrading the heating system with renewable energy equipment, as the Trust was looking to reduce its carbon footprint and utility bills. There were two main considerations when recommending a new system. The first was reliability, because of the vulnerability of many of the residents, and the second was the high demand for heating and hot water. To meet these requirements, Remeha proposed installing a hybrid heating and hot water system that combines gas absorption heat pumps (GAHPs) and condensing boilers, with a BMS control. GAHPs are gaining increasing support as an adaptable renewable solution to heating. They offer enhanced environmental and financial benefits for building operators because of their use of gas rather than electricity to drive the heat pump, and of an ammonia/water working fluid rather than HCFCs as the refrigerant. Furthermore, Lake House was Heat metre Heat circuit R enewable technology is increasingly specified as the prime source of energy for heating and water provision on both new-build and refurbishment projects. Yet recent projects have highlighted the frequent failure of these sophisticated solutions to deliver the predicted energy and carbon savings, because of renewable equipment either underperforming or failing to operate at all. When the high efficiency figure quoted by manufacturers on their product is not achieved, the cause usually stems from a failure to adhere to good system design and control, rather than from a problem with the product. This can be a cause of great frustration for manufacturers, who effectively relinquish control over a heating product as soon as it is released, despite being responsible for it while it remains under warranty. So what if manufacturers were more involved in system design? Would their knowledge of the products installation and operation lead to a more efficient system? Gas meter renewable technologies the remeha touch BMS displays the performance data of all the components of the system