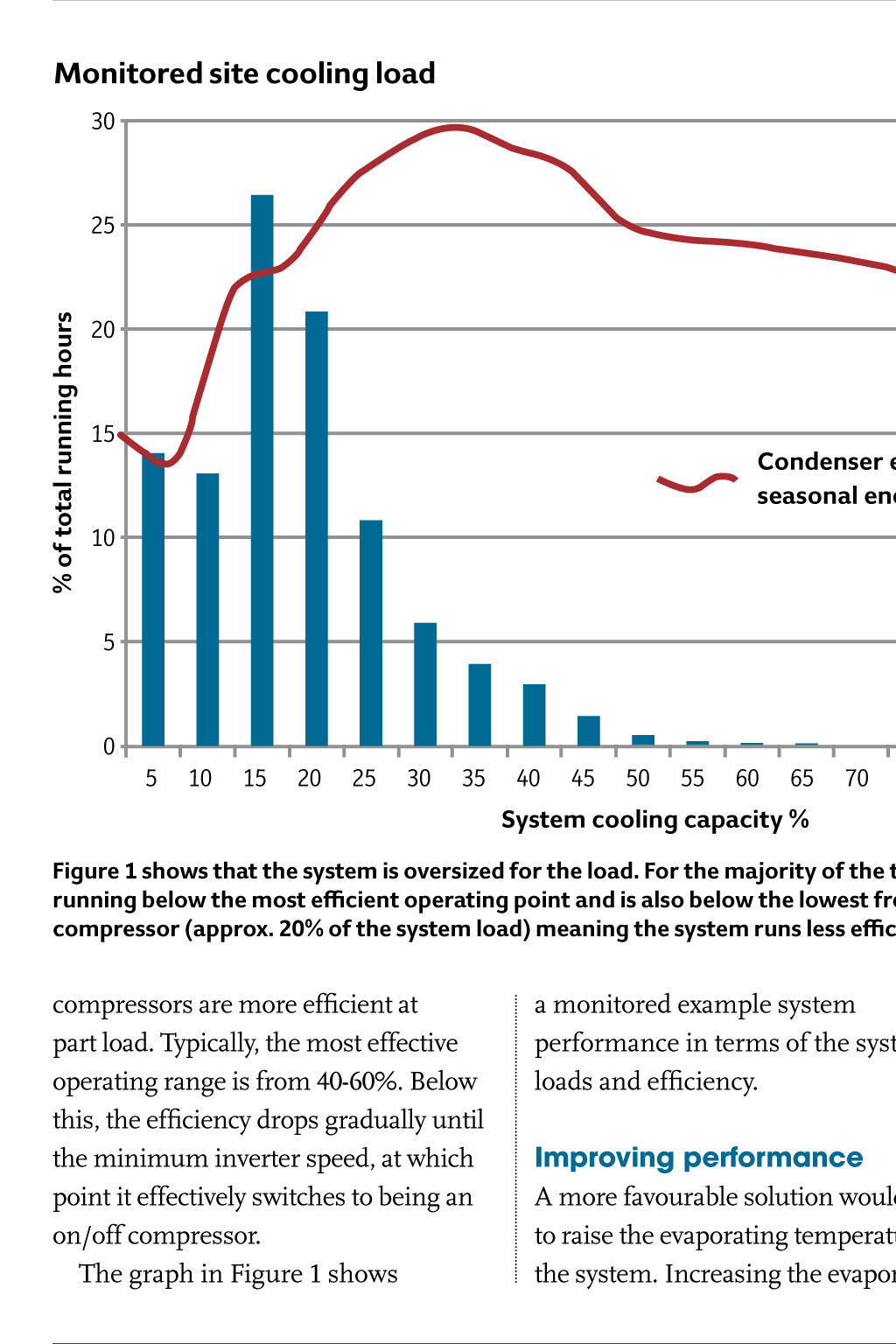

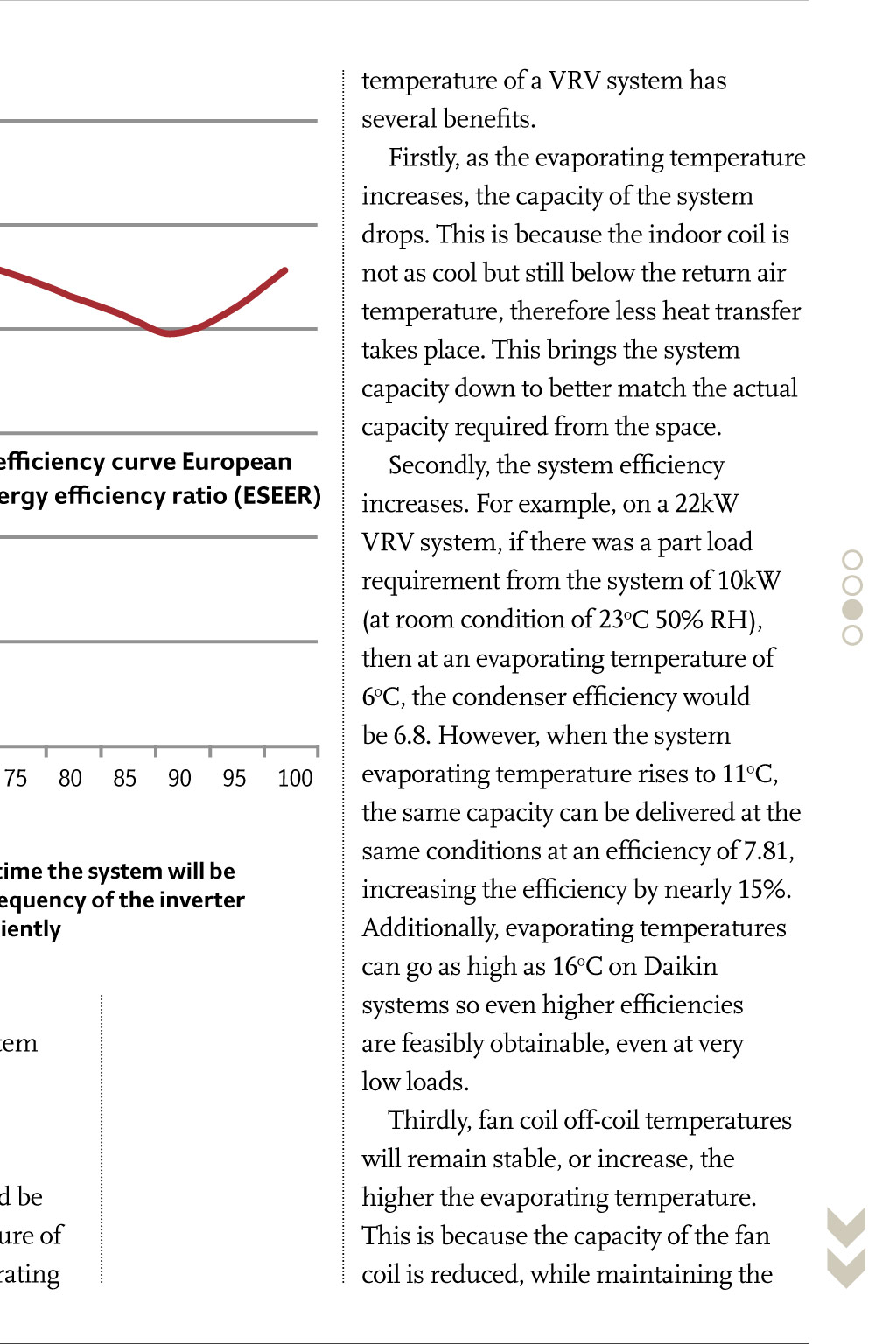

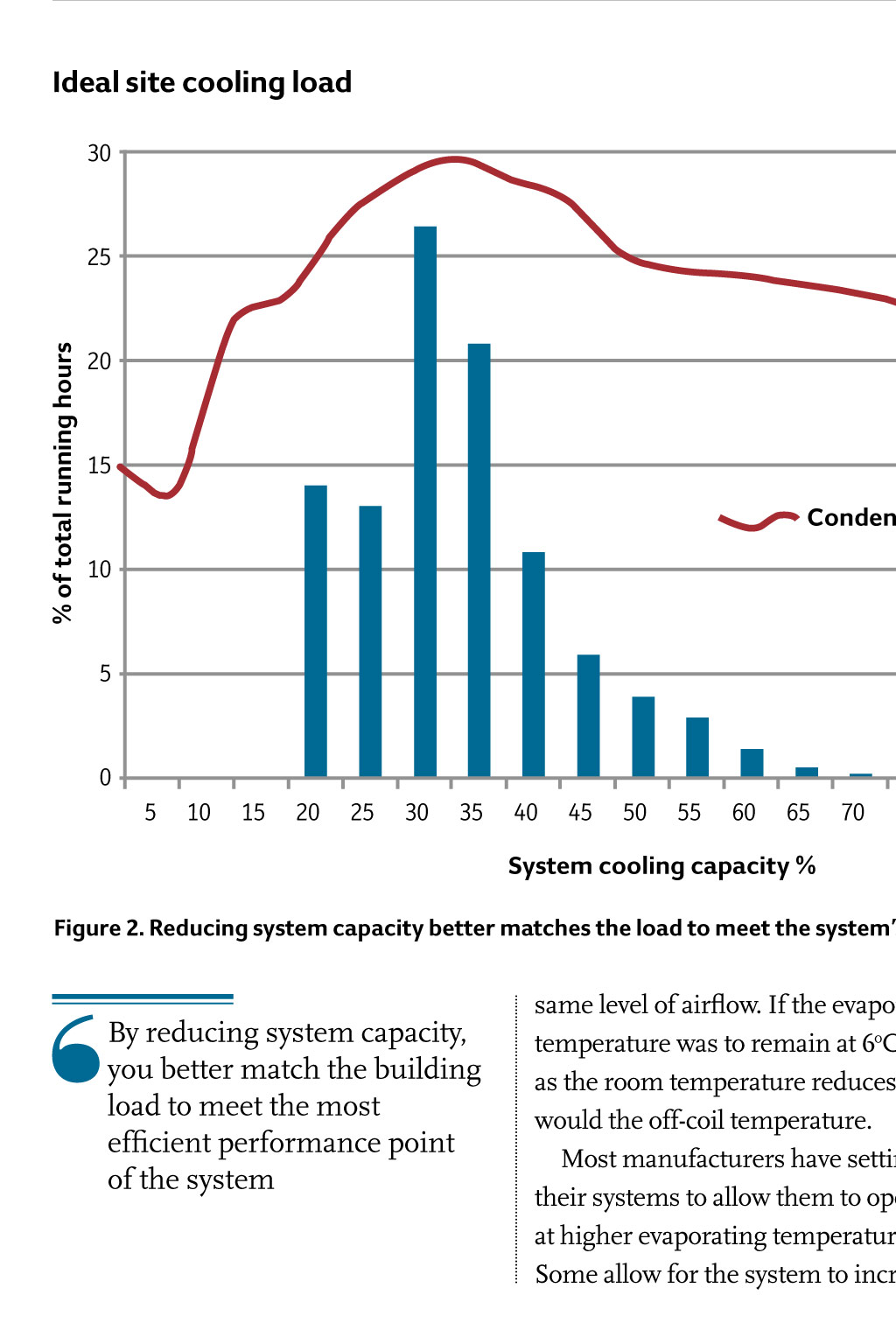

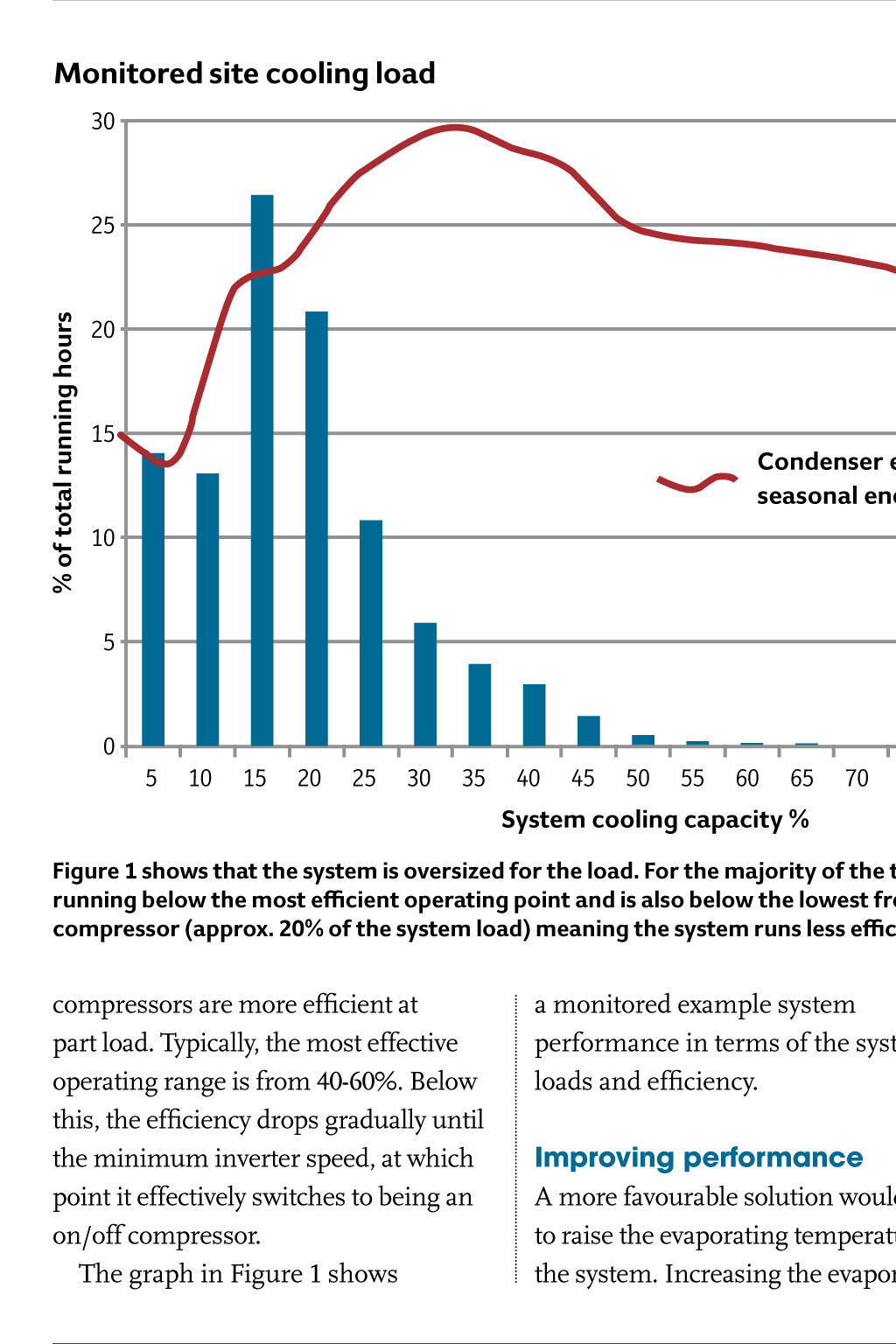

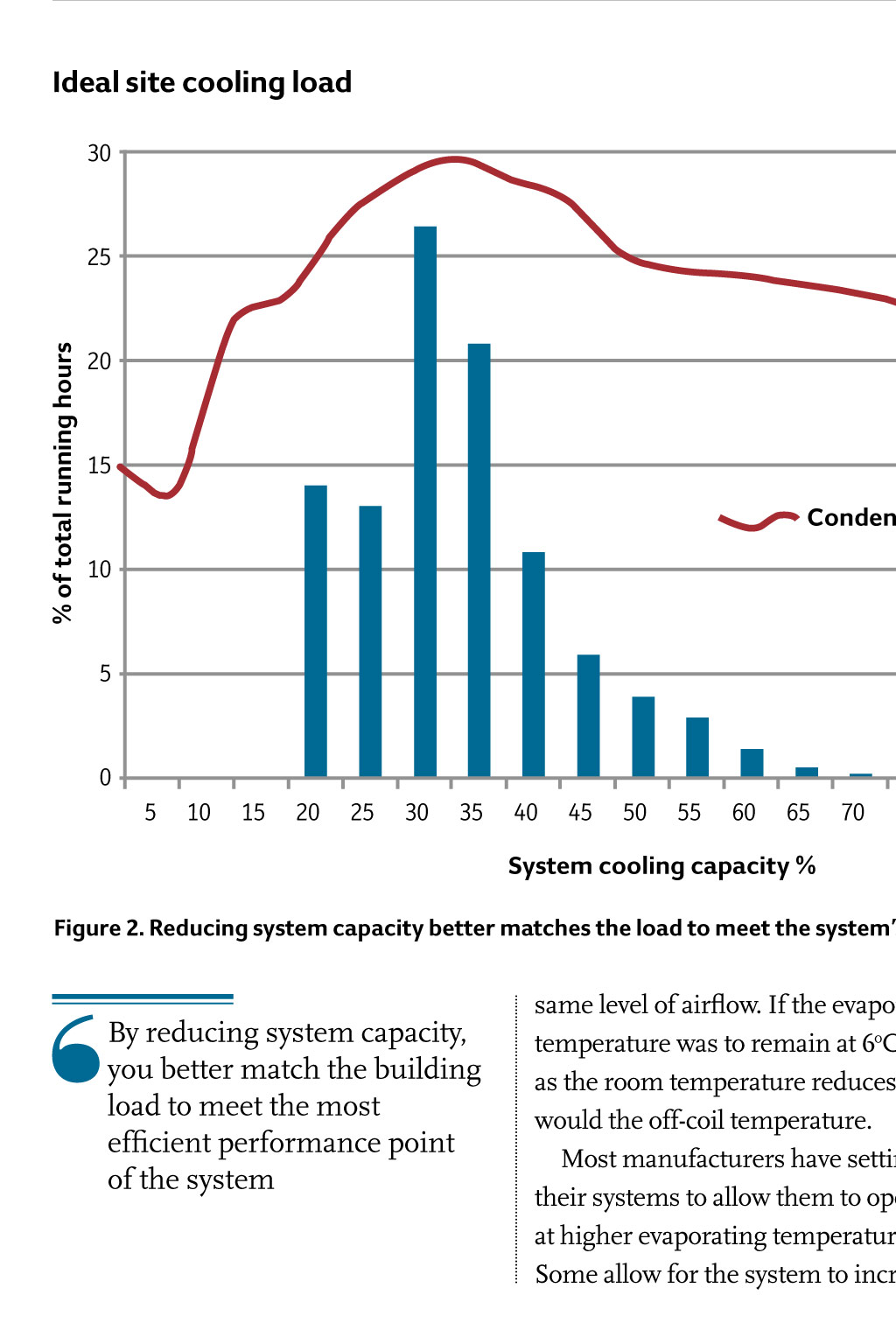

heAT And cooling sysTems ovErsiZing XXXXXX XXXXXXXXX an easy rsizing is tem ove ys esigning S when d fall into system. trap to cooling ting and ea cialist at ah VRV spe Green, ichard nes the R h exami UK, bot how to Daikin ghlights ls and hi pitfal ed system oversiz ediate an rem n phase the desig uring roject, the of any p comfort eration of consid e ants in th the occup of use of air ough the ilding thr bu ilation is and vent ditioning con r, during . Howeve y gh priorit a hi ot always hase its n design p going to the uilding is ow the b clear h fices with ially in of sed, espec be u tenants. multiple D With this in mind, its perhaps clear to see why consultants add in safety margins when calculating heating and cooling loads. The prospect of having insufficient capacity and potential for complaints is, at best, an unwelcome thought and, at worst, could lead to claims against those responsible for the design. The problem is that oversizing systems can have a large negative effect on efficiency. This was shown in Daikin research comparing variable refrigerant volume (VRV) systems in Europe and the UK. It found UK engineers were oversizing systems more than their peers on the continent. This is not an ideal situation but, as this article will explain, there are methods of increasing the energy performance of oversized systems that have already been installed. For a number of years, Daikin has been monitoring various older model VRV sites around Europe. This monitoring shows how closely the installed equipment matches the actual building loads. But the results from UK sites were surprisingly different. They demonstrated that the sites had a maximum load demand of only 45% of the nominal condenser capacity in cooling, and that the condensers were spending most of their time operating at around 20% capacity. But in heating, the maximum load was 70% of the nominal heating capacity. This raises two important points. Firstly, many building service engineers design primarily on cooling loads and, in some cases, assume the heating load will consequently be satisfied. However, this study shows that the heating demand on these systems is higher than one that may have been expected. This may be because the majority of the sample systems are in older buildings with poor thermal insulation. Any installed heating must also allow for capacity reduction during periods of defrost. Secondly, the effect on efficiency and comfort at low load it is well documented that inverter driven All these rely on historically collected, or predicted, source information that may lead to unexpectedly extreme errors for example climate data, which, for the most part, is sourced from airfields that may not be representative of the projects local climate especially for projects in built-up areas. There are methods of increasing the energy performance of oversized systems that have already been installed Why are systems oversized? Determining heat loss and gains within a space that hasnt yet been built or occupied can be predicted using various load calculation methods that range in accuracy from rules of thumb all the way through to dynamic simulation modelling software and CIBSEs TM54: Evaluating Operational Energy Performance of Buildings at the Design Stage. Monitored site cooling load 30 % of total running hours 25 20 15 Condenser efficiency curve European seasonal energy efficiency ratio (ESEER) 10 5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 100 System cooling capacity % Figure 1 shows that the system is oversized for the load. For the majority of the time the system will be running below the most efficient operating point and is also below the lowest frequency of the inverter compressor (approx. 20% of the system load) meaning the system runs less efficiently compressors are more efficient at part load. Typically, the most effective operating range is from 40-60%. Below this, the efficiency drops gradually until the minimum inverter speed, at which point it effectively switches to being an on/off compressor. The graph in Figure 1 shows a monitored example system performance in terms of the system loads and efficiency. improving performance A more favourable solution would be to raise the evaporating temperature of the system. Increasing the evaporating temperature of a VRV system has several benefits. Firstly, as the evaporating temperature increases, the capacity of the system drops. This is because the indoor coil is not as cool but still below the return air temperature, therefore less heat transfer takes place. This brings the system capacity down to better match the actual capacity required from the space. Secondly, the system efficiency increases. For example, on a 22kW VRV system, if there was a part load requirement from the system of 10kW (at room condition of 23oC 50% RH), then at an evaporating temperature of 6oC, the condenser efficiency would be 6.8. However, when the system evaporating temperature rises to 11oC, the same capacity can be delivered at the same conditions at an efficiency of 7.81, increasing the efficiency by nearly 15%. Additionally, evaporating temperatures can go as high as 16oC on Daikin systems so even higher efficiencies are feasibly obtainable, even at very low loads. Thirdly, fan coil off-coil temperatures will remain stable, or increase, the higher the evaporating temperature. This is because the capacity of the fan coil is reduced, while maintaining the Ideal site cooling load 30 % of total running hours 25 20 15 Condenser efficiency curve ESEER 10 5 0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80 85 90 95 System cooling capacity % Figure 2. Reducing system capacity better matches the load to meet the systems most efficient point By reducing system capacity, you better match the building load to meet the most efficient performance point of the system same level of airflow. If the evaporating temperature was to remain at 6oC then, as the room temperature reduces, so would the off-coil temperature. Most manufacturers have settings on their systems to allow them to operate at higher evaporating temperatures. Some allow for the system to increase 100 evaporating temperature automatically in response to the load, so that the systems can provide the correct capacity under full and part load conditions without compromising on efficiency or comfort. So, as we can see, the oversizing of systems can have a significant negative effect on efficiency. Fortunately, there are ways to overcome this issue, with systems that can automatically adjust evaporating temperatures based on system load, or by monitoring systems in an occupied building to identify the in use load profile, so that the evaporating temperature of the system can be adjusted accordingly. cJ