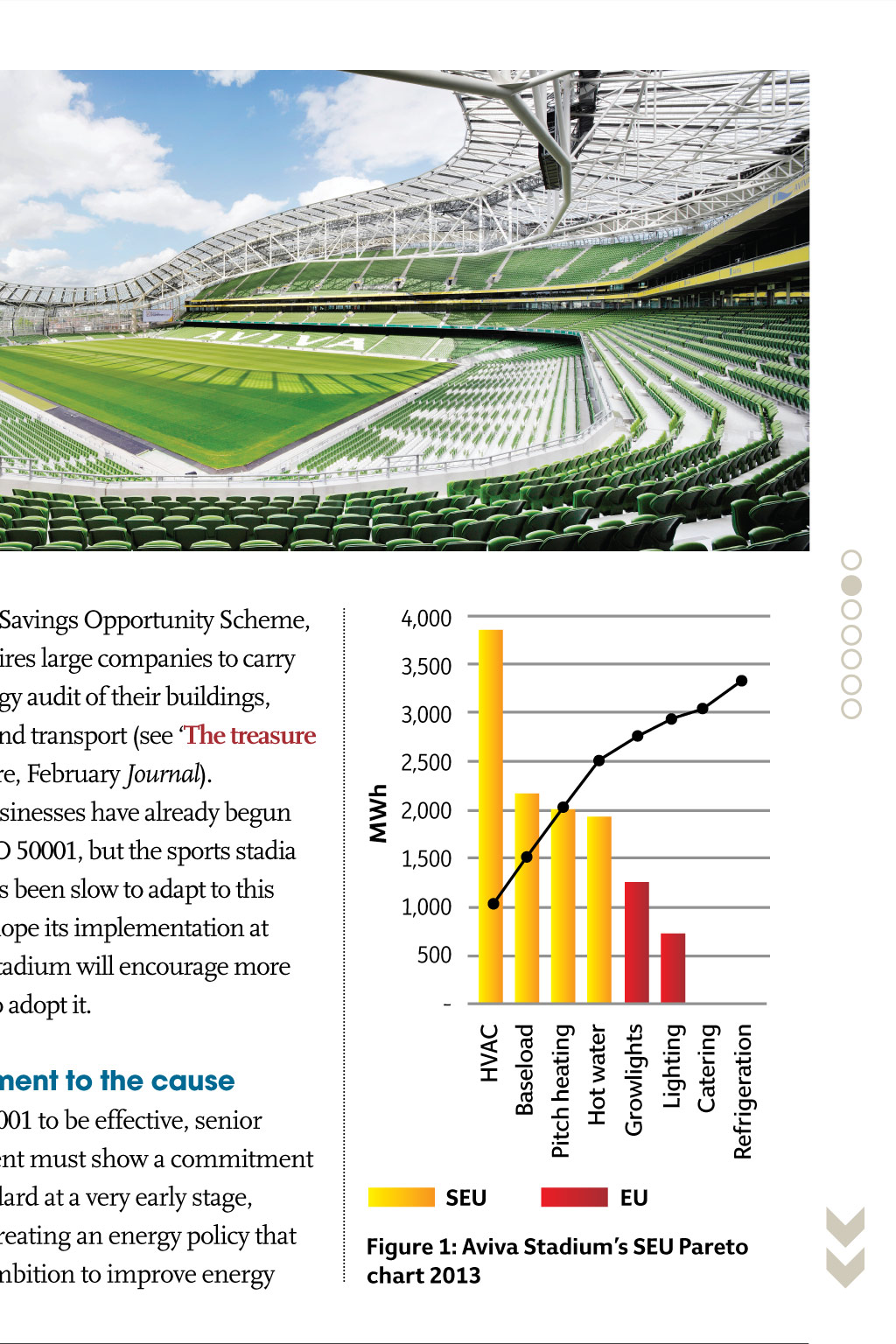

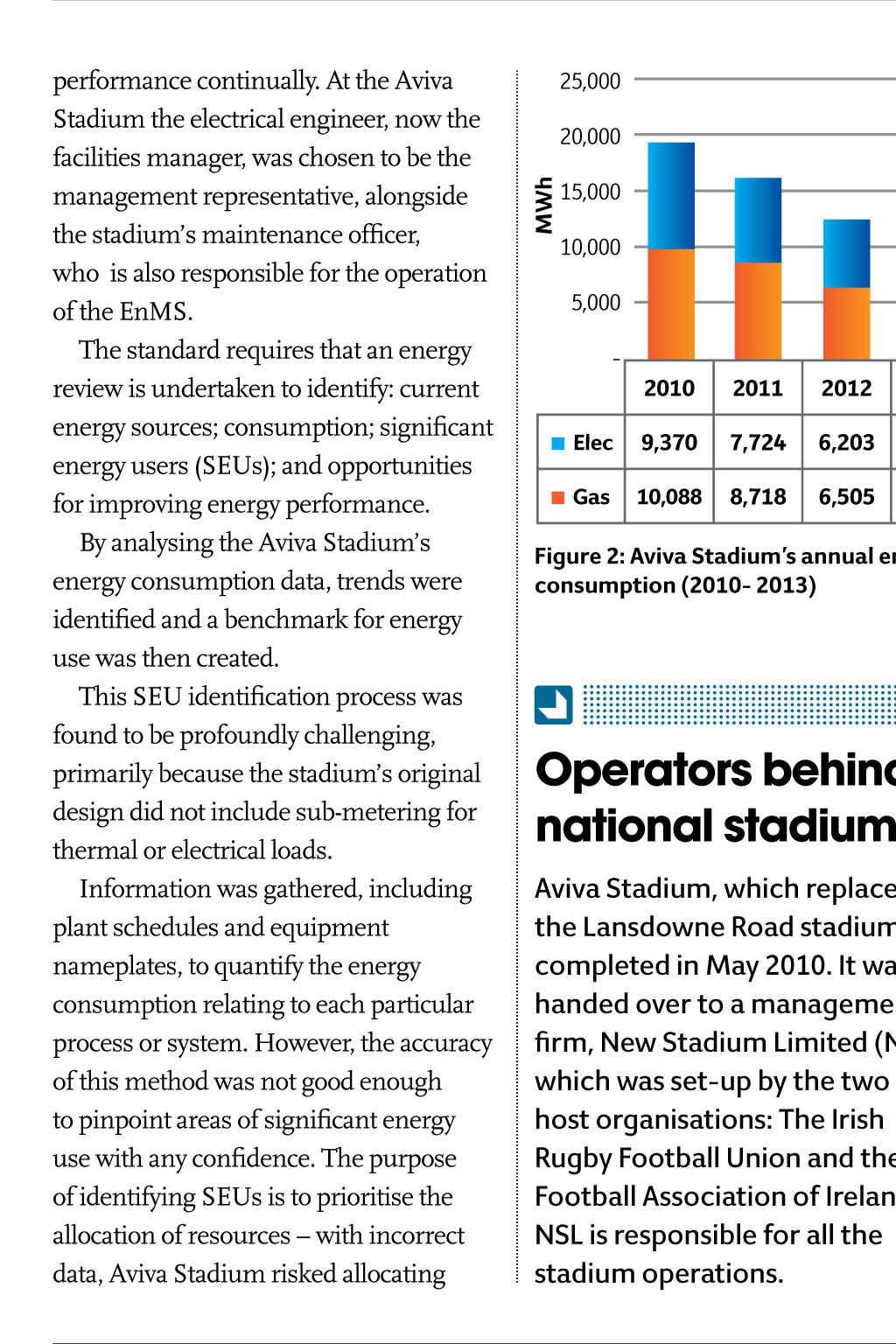

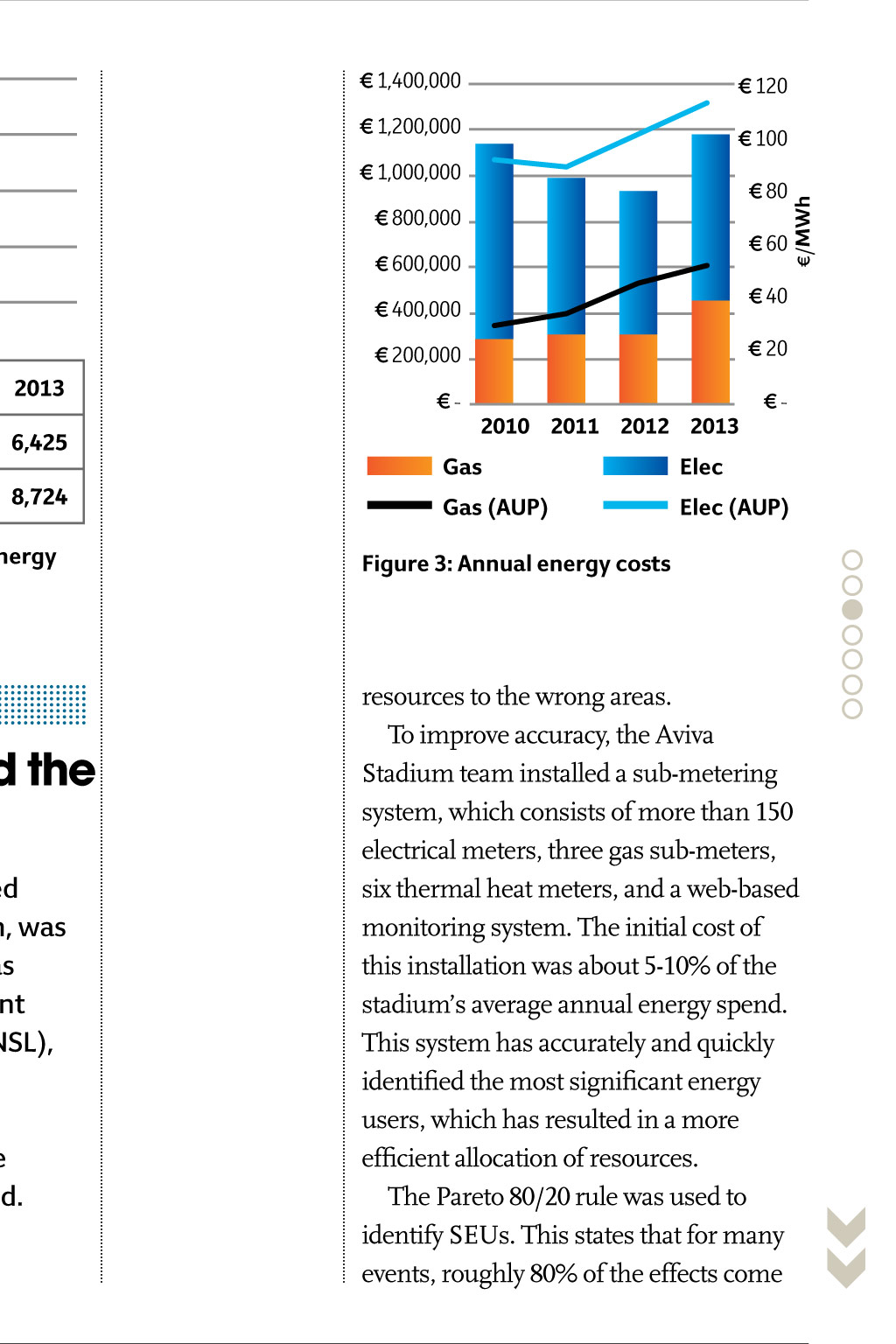

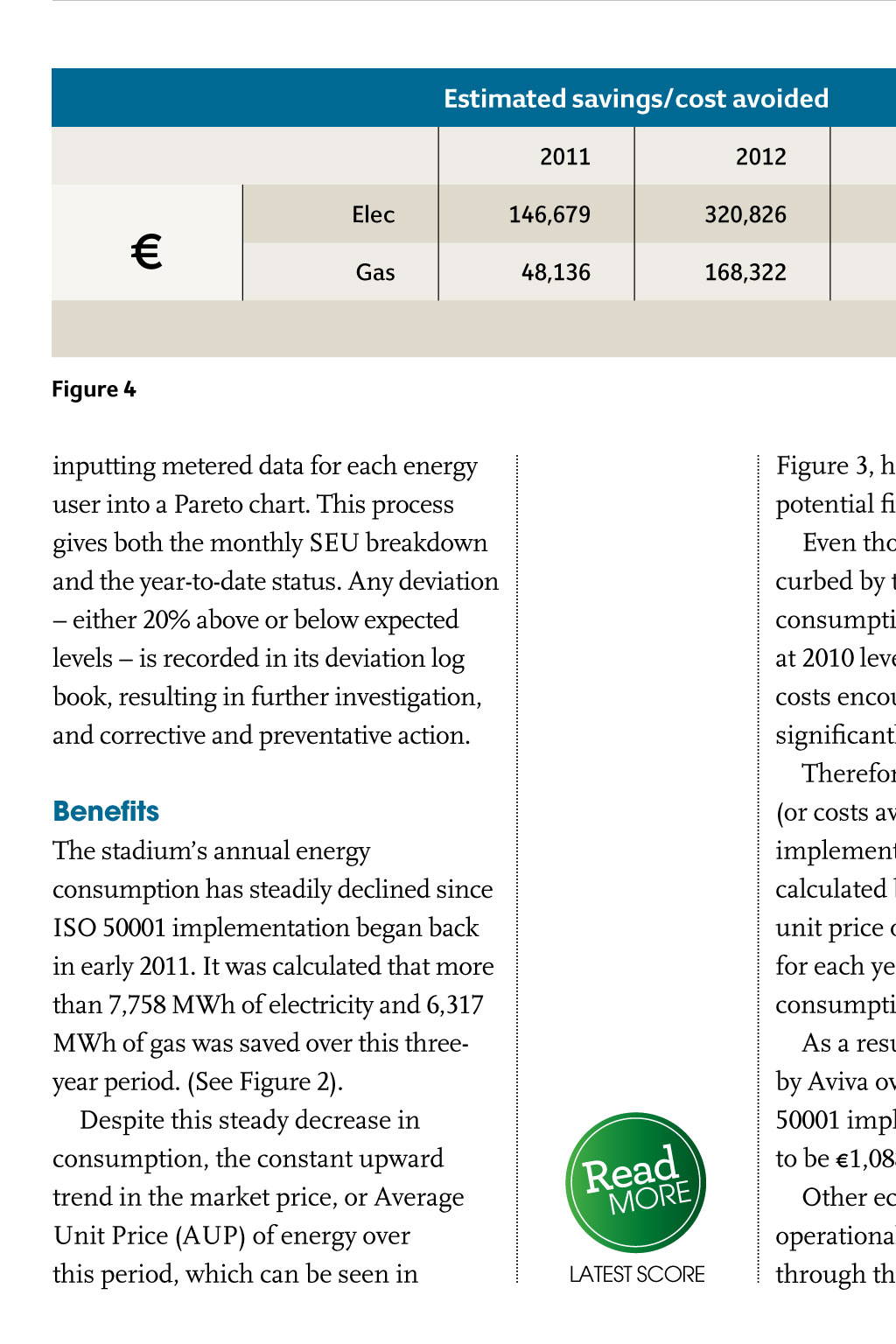

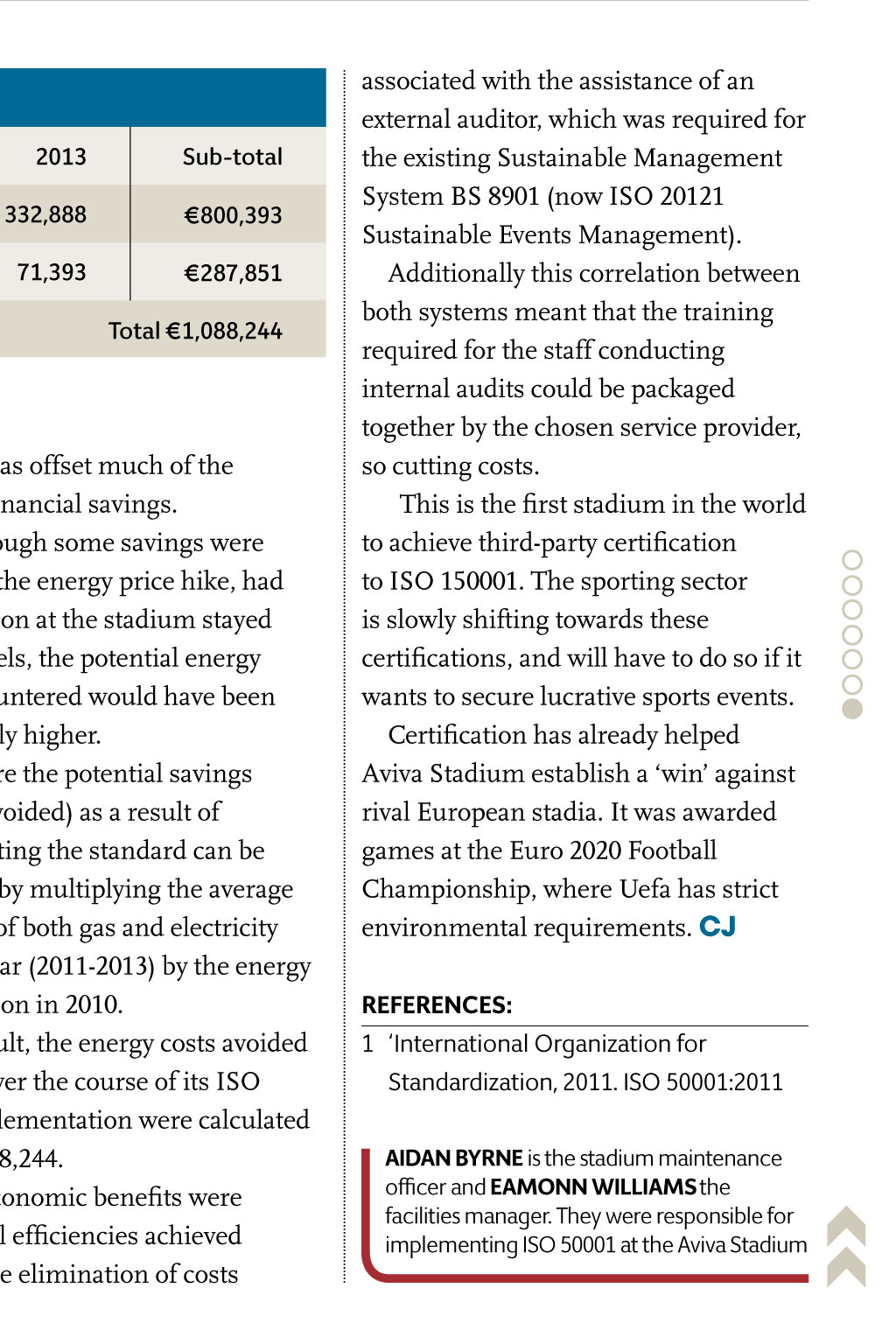

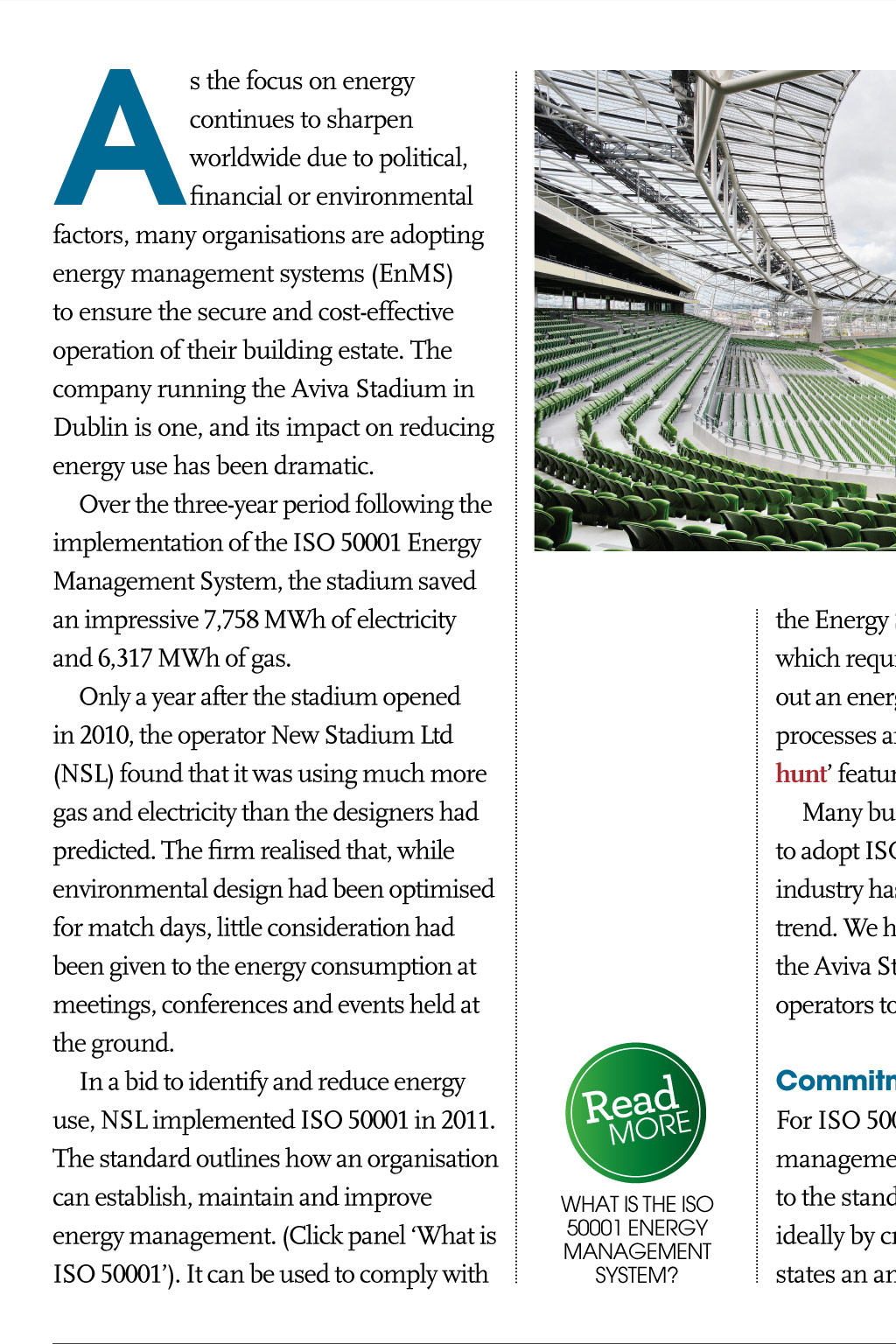

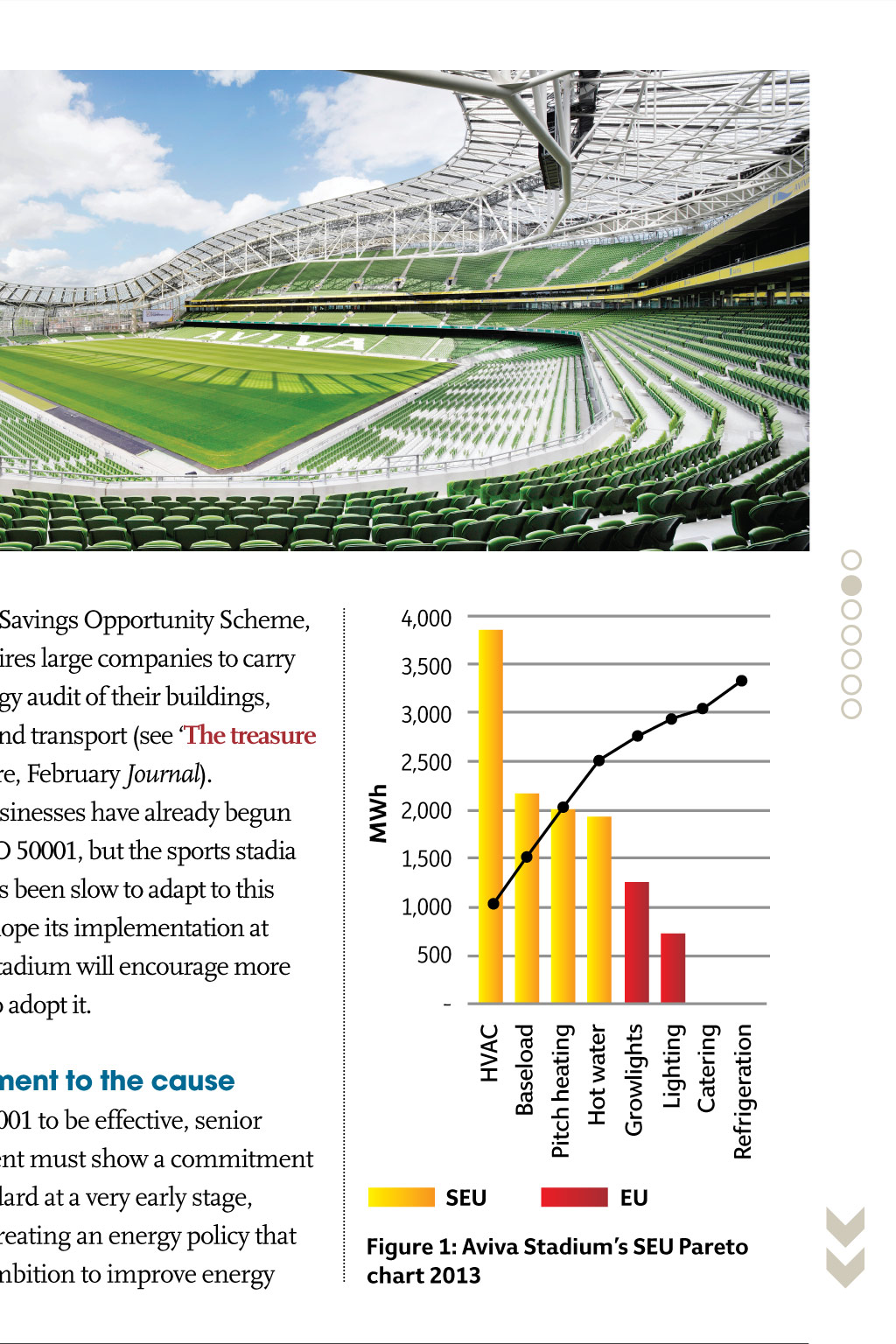

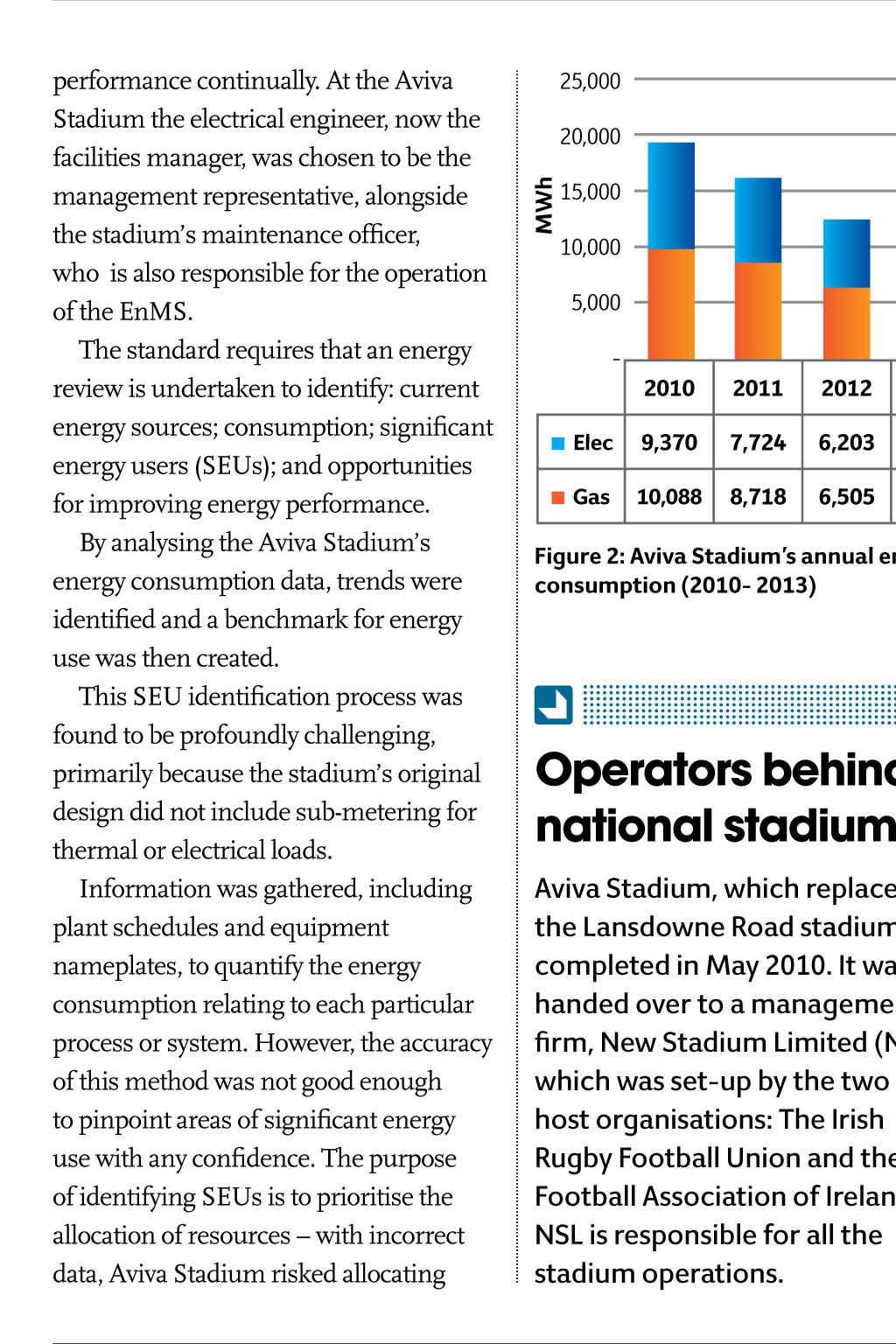

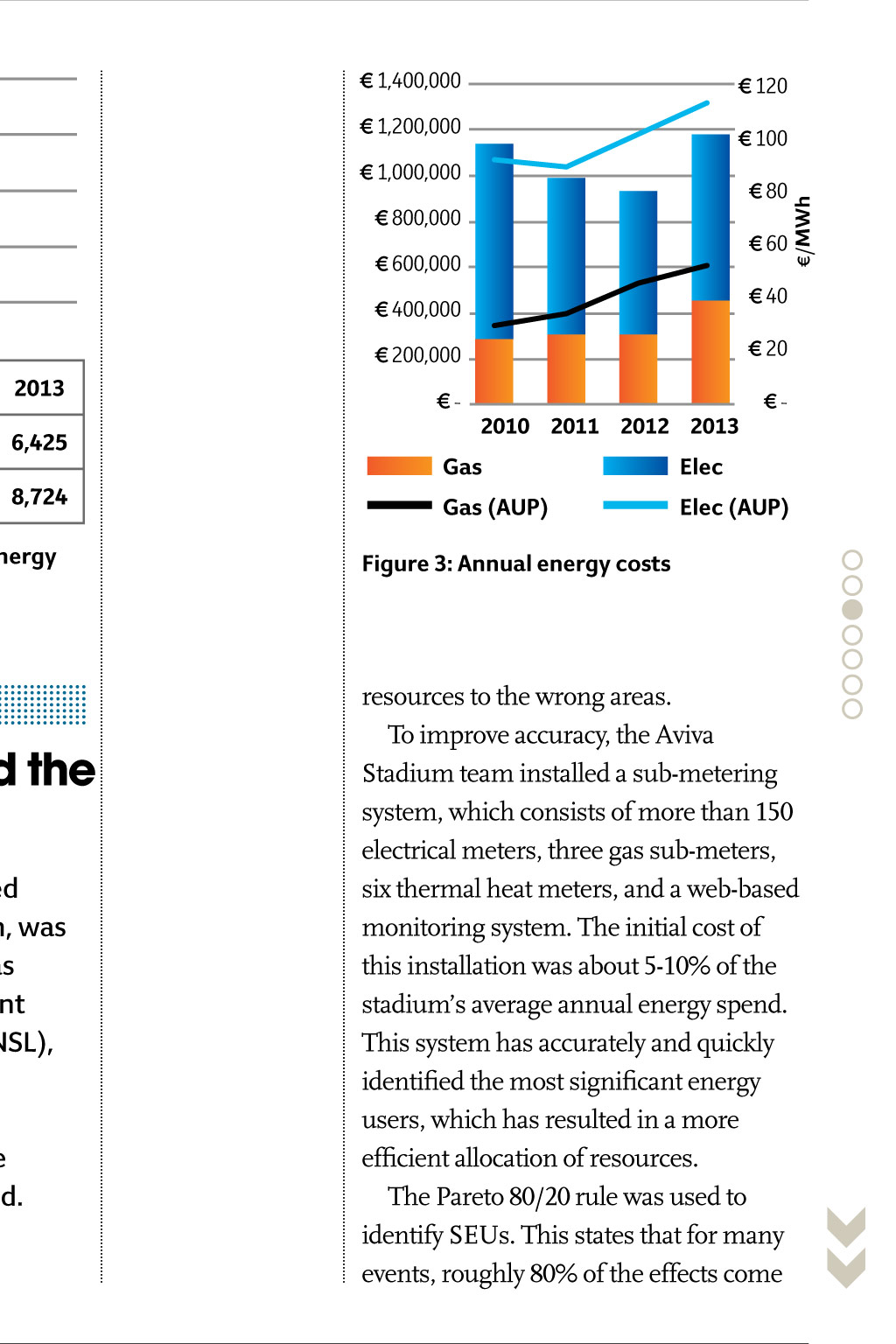

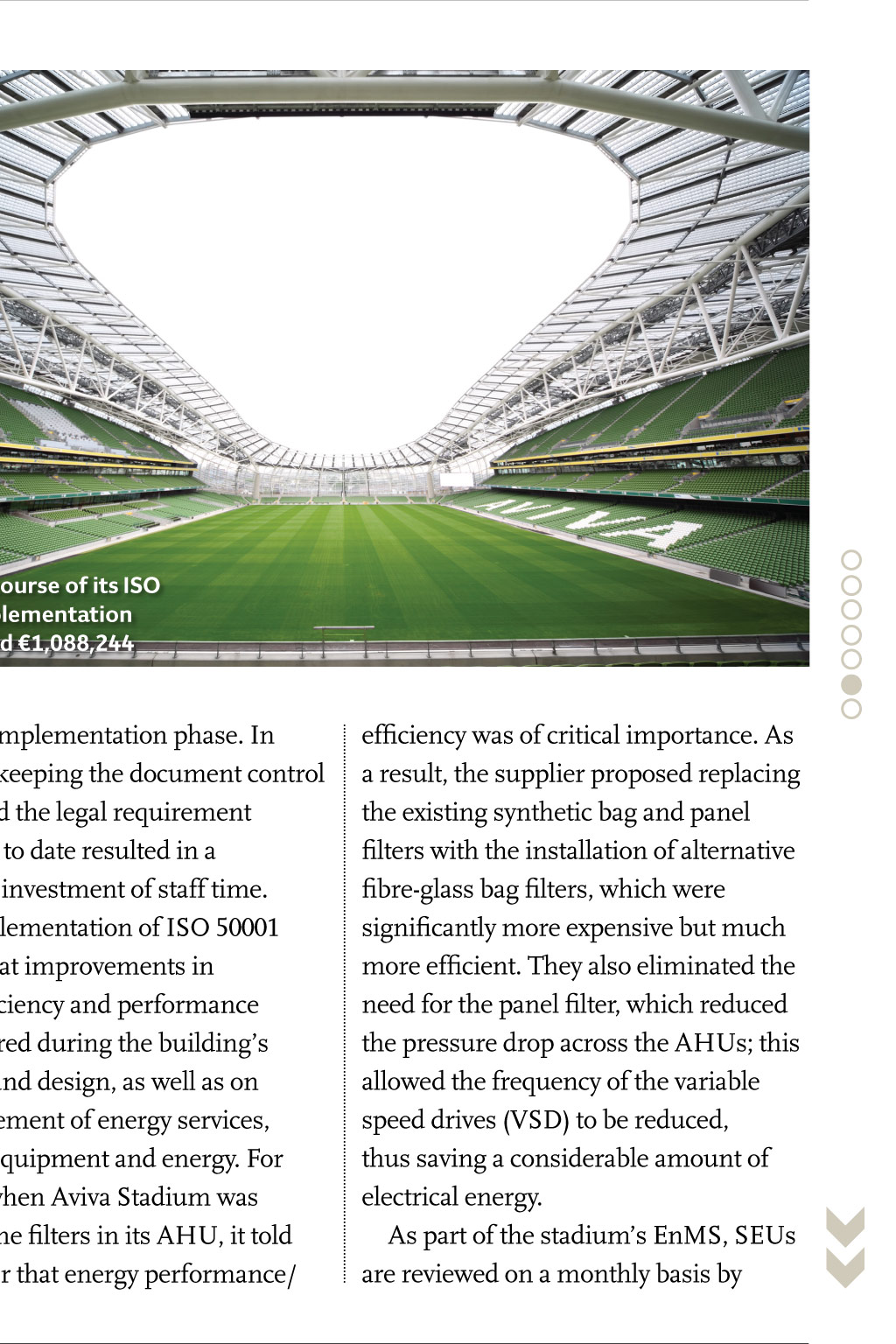

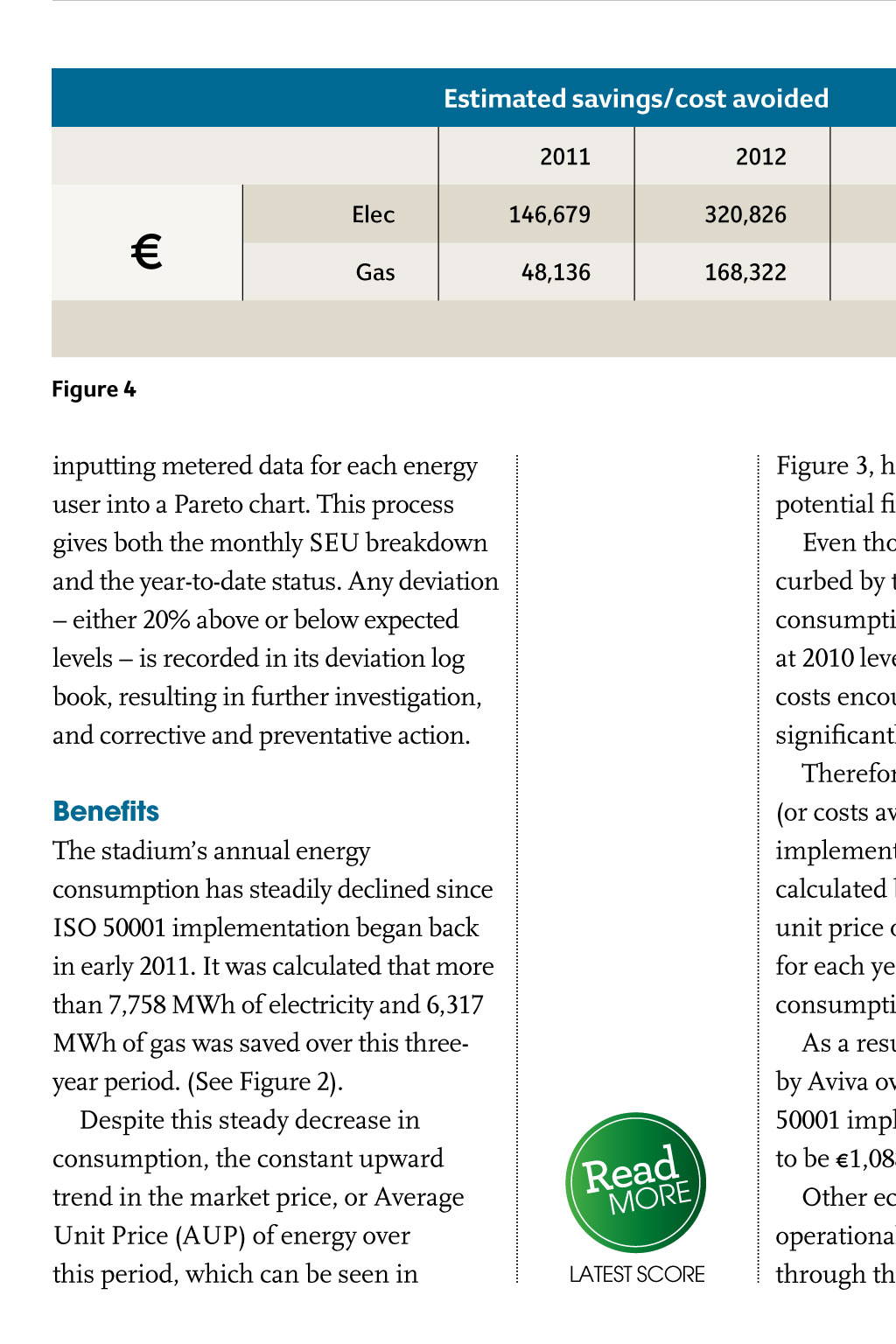

iSO 50001 Aviva stadium Aviva Stadium, the home of Irish rugby, has kicked energy waste into touch since adopting the ISO 50001 Energy Management system. Aidan Byrne and Eamonn Williams explain how the tool helped uncover 14 megawatts of energy savings in the first three years of operation FUll version in sDar JoUrnal energY dRivE A wHat is tHe iso 50001 energY management sYstem? Tactics The planning stage begins when an organisation establishes, implements, and maintains documented energy objectives and targets. It is important that these objectives and targets be 3,500 3,000 2,500 2,000 1,500 1,000 500 SEU Refrigeration Lighting Catering Growlights Hot water Pitch heating - EU Figure 1: Aviva Stadiums SEU Pareto chart 2013 1,400,000 120 20,000 1,200,000 100 1,000,000 15,000 80 800,000 10,000 60 600,000 5,000 400,000 40 - 200,000 20 - /MWh 25,000 - 2010 2011 2012 2013 Elec 9,370 7,724 6,203 6,425 Gas 10,088 8,718 6,505 8,724 2010 2011 2012 2013 Gas Elec Gas (AUP) Figure 2: Aviva Stadiums annual energy consumption (2010- 2013) Elec (AUP) Figure 3: Annual energy costs resources to the wrong areas. To improve accuracy, the Aviva Stadium team installed a sub-metering system, which consists of more than 150 electrical meters, three gas sub-meters, six thermal heat meters, and a web-based monitoring system. The initial cost of this installation was about 5-10% of the stadiums average annual energy spend. This system has accurately and quickly identified the most significant energy users, which has resulted in a more efficient allocation of resources. The Pareto 80/20 rule was used to identify SEUs. This states that for many events, roughly 80% of the effects come Operators behind the national stadium Aviva Stadium, which replaced the Lansdowne Road stadium, was completed in May 2010. It was handed over to a management firm, New Stadium Limited (NSL), which was set-up by the two host organisations: The Irish Rugby Football Union and the Football Association of Ireland. NSL is responsible for all the stadium operations. installation of heat meters will yield more specific data over the coming heating session. Aviva Stadiums current SEUs are the HVAC, pitch-heating and domestic hot water systems and the electrical baseload. Relevant variables were identified for each. This proved to be almost impossible during initial stages at the stadium because the lack of submetering meant operators were unable from 20% of the causes. By identifying 80% of the energy consumed as significant, the systems, plant, or equipment responsible for this energy use, can be identified as the sites SEUs (see Aviva Stadiums SEU Pareto chart in Figure 3). The Pareto chart was created using a mixture of metered and tabulated data, so its accuracy is not absolute. This is being corrected by staff; recent the reprogramming of the Building Management System (BMS). This allowed us to control the operation of HVAC in different areas and times, and only cost Aviva 2,000. As the designers primary design brief was for large pitch events, this resulted in far too much plant being called to run by the BMS when each space was in use. In some cases, it was found that air-handling units and fans were running despite having no impact on event spaces. After making this change to the BMS, a regression analysis was completed the following year; it showed an R2 (coefficient of determination) of 0.9 for the heating system. This indicated a strong relationship between gas consumption and external temperature (the HDDs versus the gas consumed). Before this change in 2011 this was not the case, as the R2 value was 0.7 meaning the heating system could be out of control. commitment to the cause For ISO 50001 to be effective, senior management must show a commitment to the standard at a very early stage, ideally by creating an energy policy that states an ambition to improve energy 4,000 HVAC Baseload eade Rmor MWh performance continually. At the Aviva Stadium the electrical engineer, now the facilities manager, was chosen to be the management representative, alongside the stadiums maintenance officer, who is also responsible for the operation of the EnMS. The standard requires that an energy review is undertaken to identify: current energy sources; consumption; significant energy users (SEUs); and opportunities for improving energy performance. By analysing the Aviva Stadiums energy consumption data, trends were identified and a benchmark for energy use was then created. This SEU identification process was found to be profoundly challenging, primarily because the stadiums original design did not include sub-metering for thermal or electrical loads. Information was gathered, including plant schedules and equipment nameplates, to quantify the energy consumption relating to each particular process or system. However, the accuracy of this method was not good enough to pinpoint areas of significant energy use with any confidence. The purpose of identifying SEUs is to prioritise the allocation of resources with incorrect data, Aviva Stadium risked allocating the Energy Savings Opportunity Scheme, which requires large companies to carry out an energy audit of their buildings, processes and transport (see The treasure hunt feature, February Journal). Many businesses have already begun to adopt ISO 50001, but the sports stadia industry has been slow to adapt to this trend. We hope its implementation at the Aviva Stadium will encourage more operators to adopt it. MWh s the focus on energy continues to sharpen worldwide due to political, financial or environmental factors, many organisations are adopting energy management systems (EnMS) to ensure the secure and cost-effective operation of their building estate. The company running the Aviva Stadium in Dublin is one, and its impact on reducing energy use has been dramatic. Over the three-year period following the implementation of the ISO 50001 Energy Management System, the stadium saved an impressive 7,758 MWh of electricity and 6,317 MWh of gas. Only a year after the stadium opened in 2010, the operator New Stadium Ltd (NSL) found that it was using much more gas and electricity than the designers had predicted. The firm realised that, while environmental design had been optimised for match days, little consideration had been given to the energy consumption at meetings, conferences and events held at the ground. In a bid to identify and reduce energy use, NSL implemented ISO 50001 in 2011. The standard outlines how an organisation can establish, maintain and improve energy management. (Click panel What is ISO 50001). It can be used to comply with to differentiate between separate loads. Energy Performance Indicators (EnPIs) are crucial in the monitoring and measurement of the energy performance of each SEU, and they should be used as a means of identifying significant deviations in performance. One example of an EnPI used by Aviva Stadium, is the measure of external temperature versus the amount of energy consumed by the heating system, where kWh is the energy consumption (for instance, gas) and the heating degree days (HDD), using 15C as the base temperature. For example, in November 2013, 1,336,298 kWh of gas was consumed with 270 HDD. This equates to a ratio of 4,949 kWh/HDD. During the previous November, only 879,712 kWh of gas was consumed, despite having 272 HDD, and therefore a lower ratio of 3,232 kWh/HDD. This then identified a significant deviation in gas consumption for that month. The similar EnPI was used for the under-pitch heating. In this case, the HDD base temperature used is around 10C. This is because grass is expected to grow at, and above, 10C. One of the most significant opportunities for improvement was approved by top management and communicated to those who may have an impact on them. They must also be looked at on a regular basis and during the annual management review. One objective was to improve the energy performance of the kiosk areas by shutting/powering them down in between events. This was verified by the use of electrical meters, and was also externally verified by an external energy consultant who conducted a separate measurement and verification plan on behalf of the stadiums electricity supplier. The objective was achieved, and 306,124kWh was saved in 2013. It is critical that sports stadia management bears in mind its obligations to governing sporting bodies when reviewing requirements. For example, the Aviva Stadium has to provide 2,500 lux of illuminance on the pitch for broadcasting purposes, so floodlights may sometimes be needed during daylight hours. It is critical that sports stadia management bears in mind its obligations to governing sporting bodies when reviewing requirements Putting plans into play Energy awareness plays a huge role in the success of any energy management system. During the implementation at the Aviva Stadium, a training needsanalysis was undertaken for all people Over the course of its ISO 50001 implementation Aviva saved 1,088,244 the initial implementation phase. In particular, keeping the document control register and the legal requirement register up to date resulted in a significant investment of staff time. The implementation of ISO 50001 requires that improvements in energy efficiency and performance be considered during the buildings operation and design, as well as on the procurement of energy services, products, equipment and energy. For example, when Aviva Stadium was replacing the filters in its AHU, it told the supplier that energy performance/ who have an effect on the stadiums significant energy users. A list of the required training and competencies was compiled and a training register created. This identified the training needs of each person, and which standard operating procedure (SOP) to be followed. Documents relating to EnMS must be legible, available and up-to-date. The energy team at Aviva found that the vast amounts of documentation required (caused in part by third-party certification) often hampered any actual energy management progress during Estimated savings/cost avoided 2011 2012 2013 Sub-total Elec 146,679 320,826 332,888 800,393 Gas 48,136 168,322 71,393 287,851 Total 1,088,244 Figure 4 inputting metered data for each energy user into a Pareto chart. This process gives both the monthly SEU breakdown and the year-to-date status. Any deviation either 20% above or below expected levels is recorded in its deviation log book, resulting in further investigation, and corrective and preventative action. benefits The stadiums annual energy consumption has steadily declined since ISO 50001 implementation began back in early 2011. It was calculated that more than 7,758 MWh of electricity and 6,317 MWh of gas was saved over this threeyear period. (See Figure 2). Despite this steady decrease in consumption, the constant upward trend in the market price, or Average Unit Price (AUP) of energy over this period, which can be seen in eade Rmor latest score Figure 3, has offset much of the potential financial savings. Even though some savings were curbed by the energy price hike, had consumption at the stadium stayed at 2010 levels, the potential energy costs encountered would have been significantly higher. Therefore the potential savings (or costs avoided) as a result of implementing the standard can be calculated by multiplying the average unit price of both gas and electricity for each year (2011-2013) by the energy consumption in 2010. As a result, the energy costs avoided by Aviva over the course of its ISO 50001 implementation were calculated to be 1,088,244. Other economic benefits were operational efficiencies achieved through the elimination of costs wHat is tHe iso 50001 energY management sYstem? ISO 50001 outlines rules for its implementation, but does not impose any definitive quantitative requirements for energy performance. It says an organisation should strive to achieve commitments outlined in its energy policy. It does not enforce the obligations with which an organisation must comply in order to meet its legal and other requirements. The ISO 50001 standard uses the Plan-Do-Check-Act (PDCA) methodology to improve energy use continually in an organisation by incorporating energy-management practices into everyday organisational practices. Plan: conduct the energy review and establish the baseline, energy performance indicators (EnPIs), objectives, targets and action plans necessary to deliver results in accordance with the organisations energy policy. Do: implement the energy management action plans. Check: monitor and measure processes and key characteristics of operations that determine energy performance against the policy and objectives, and report the results. Act: continually take actions to improve energy performance and the EnMS. efficiency was of critical importance. As a result, the supplier proposed replacing the existing synthetic bag and panel filters with the installation of alternative fibre-glass bag filters, which were significantly more expensive but much more efficient. They also eliminated the need for the panel filter, which reduced the pressure drop across the AHUs; this allowed the frequency of the variable speed drives (VSD) to be reduced, thus saving a considerable amount of electrical energy. As part of the stadiums EnMS, SEUs are reviewed on a monthly basis by associated with the assistance of an external auditor, which was required for the existing Sustainable Management System BS 8901 (now ISO 20121 Sustainable Events Management). Additionally this correlation between both systems meant that the training required for the staff conducting internal audits could be packaged together by the chosen service provider, so cutting costs. This is the first stadium in the world to achieve third-party certification to ISO 150001. The sporting sector is slowly shifting towards these certifications, and will have to do so if it wants to secure lucrative sports events. Certification has already helped Aviva Stadium establish a win against rival European stadia. It was awarded games at the Euro 2020 Football Championship, where Uefa has strict environmental requirements. cJ REFERENCES: 1 International Organization for Standardization, 2011. ISO 50001:2011 AIdAN BYRNE is the stadium maintenance officer and EAMONN WILLIAMS the facilities manager. They were responsible for implementing ISO 50001 at the Aviva Stadium FUll version in sDar JoUrnal A full version of this paper first appeared in the SDAR Journal (www.arrow.dit.ie/sdar) Vol 2 Issue 1. The SDAR Journal is the journal for Sustainable Design and Applied Research in Engineering and the Built Environment, published by CIBSE Ireland and the Dublin Institute of Technology. It is a peer-reviewed journal for first-time publishers of evidence-based research papers, but authors are engineers or a collaboration of working engineers and academics about building services applications. Details about submissions are available on the website, or by contacting the editor, Dr Kevin Kelly, directly at kevin.kelly@dit.ie latest score Since this article was written, Aviva Stadium revealed that in 2014 the gas consumed was 7,026,982 kWh and the electricity 5,481,586 kWh. When normalising the gas consumption against the external temperature (or heating degree days), much of this reduction from 2013 figures is caused by the drop from 2,312 HDD in 2013 to 2069 HDD in 2014.