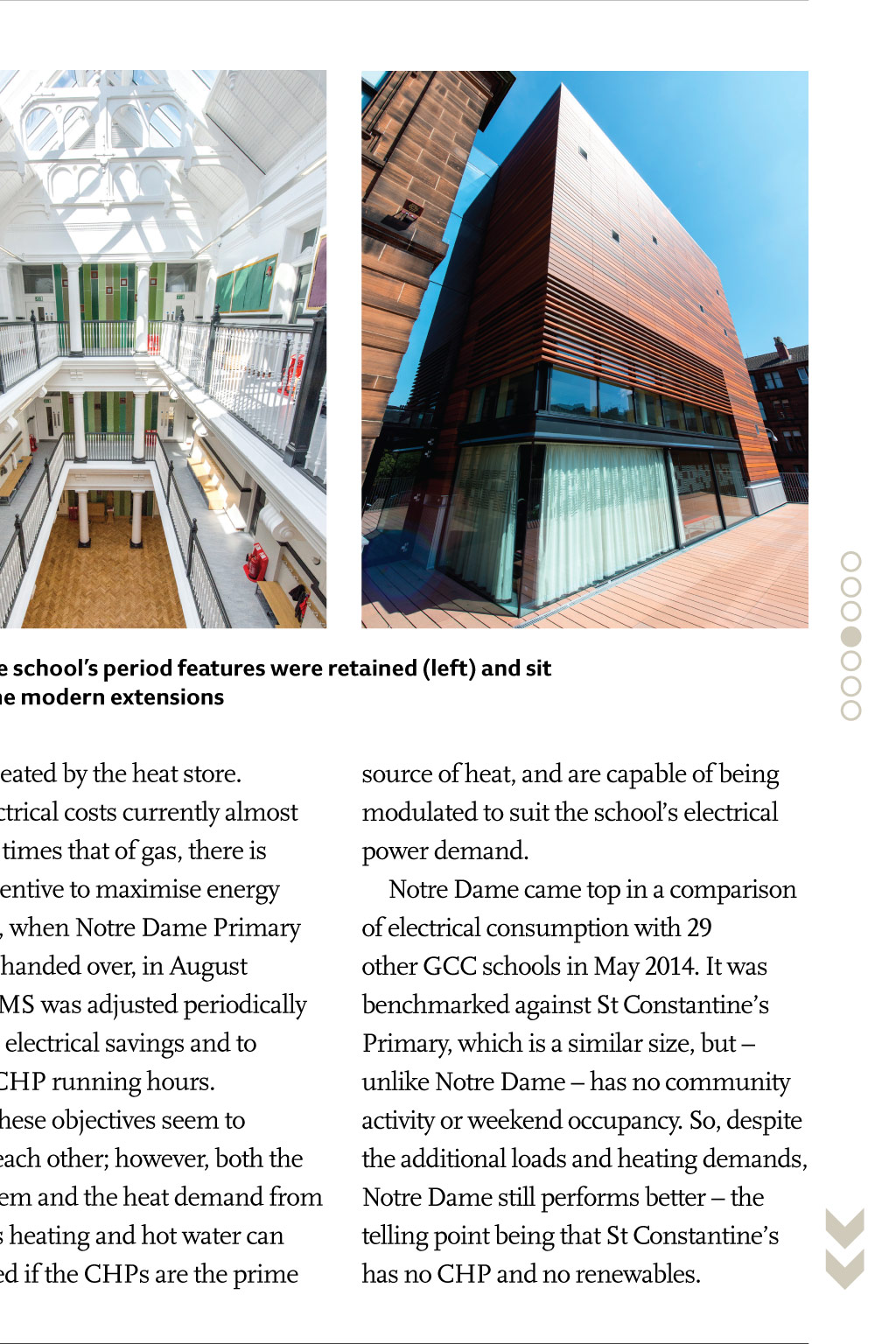

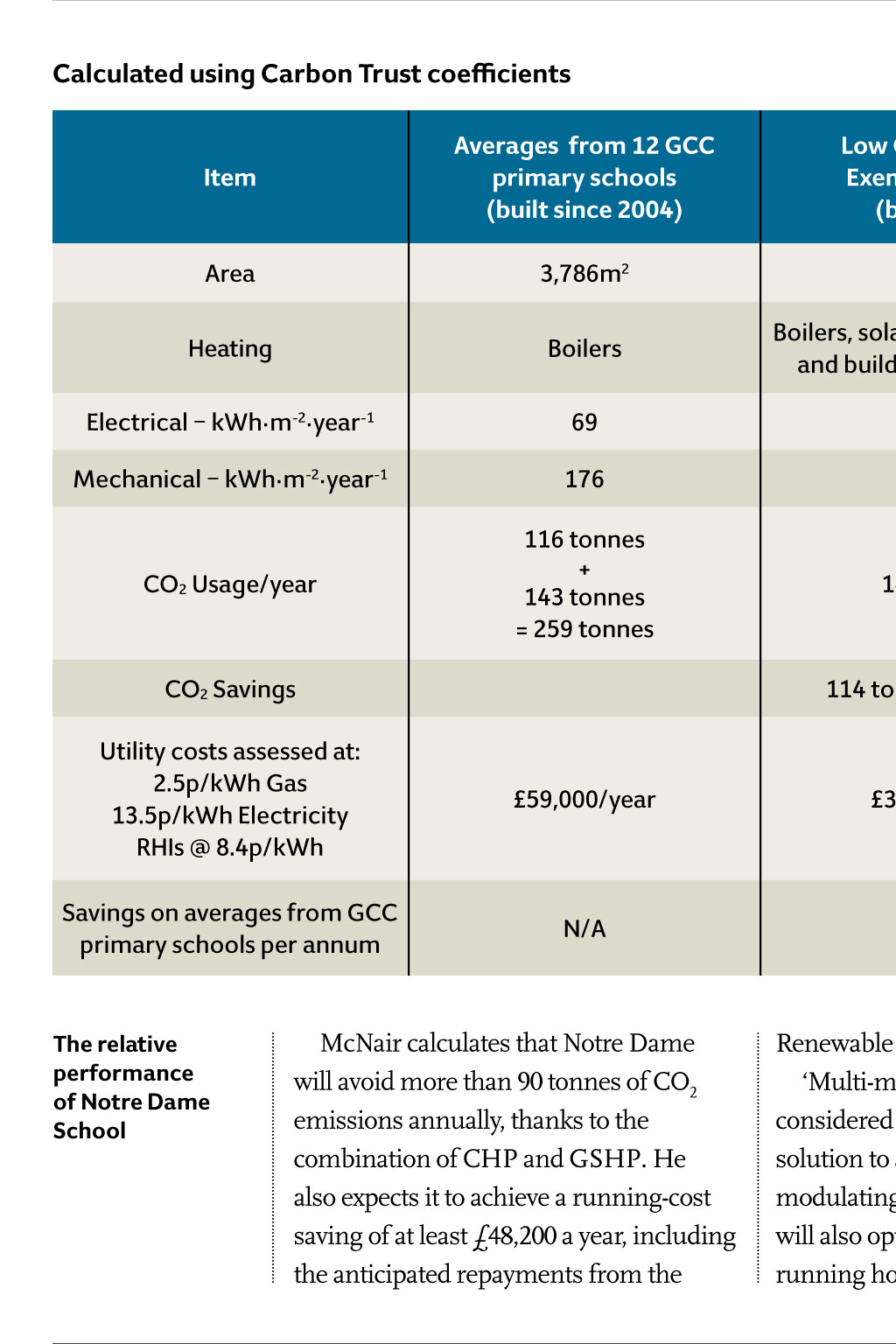

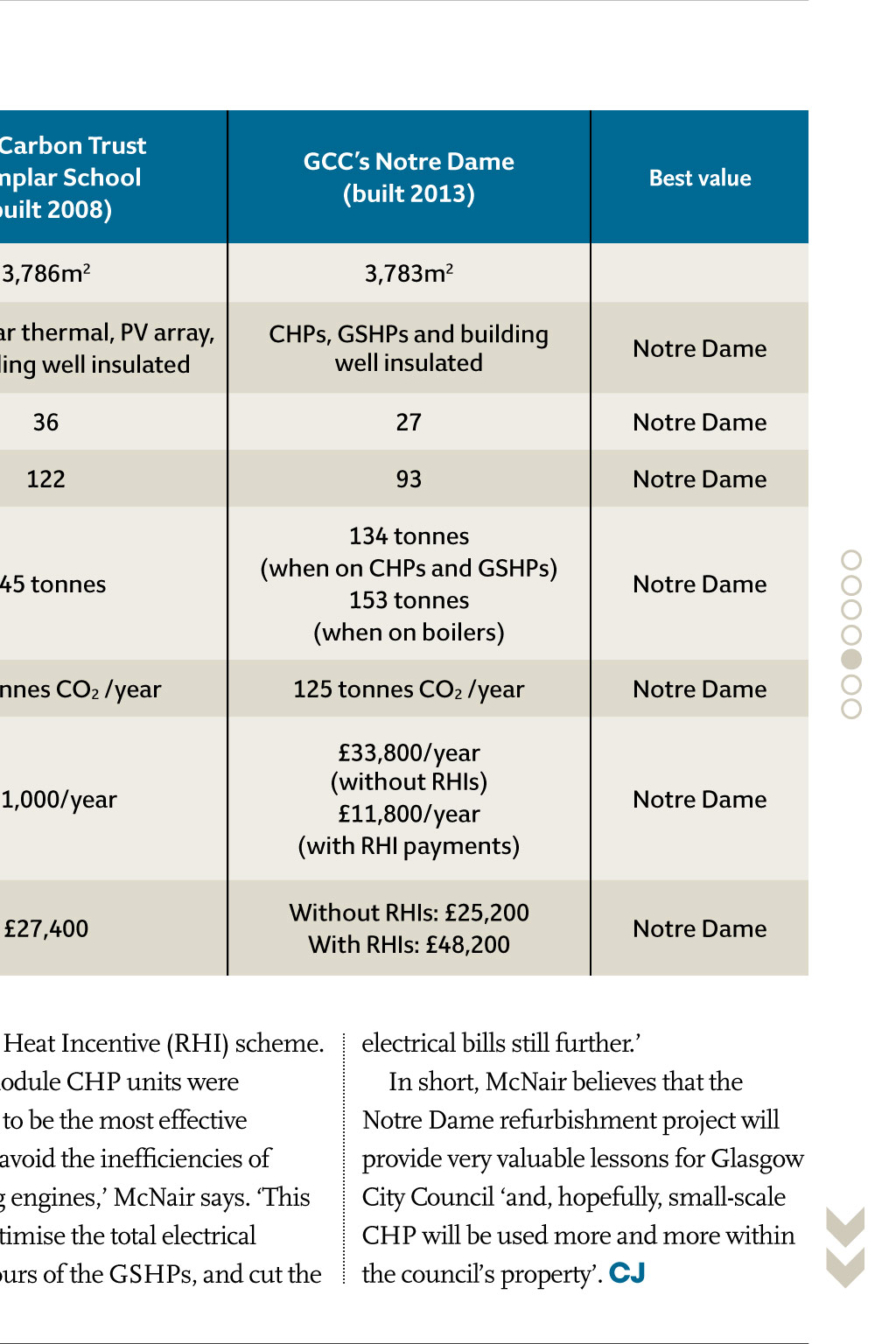

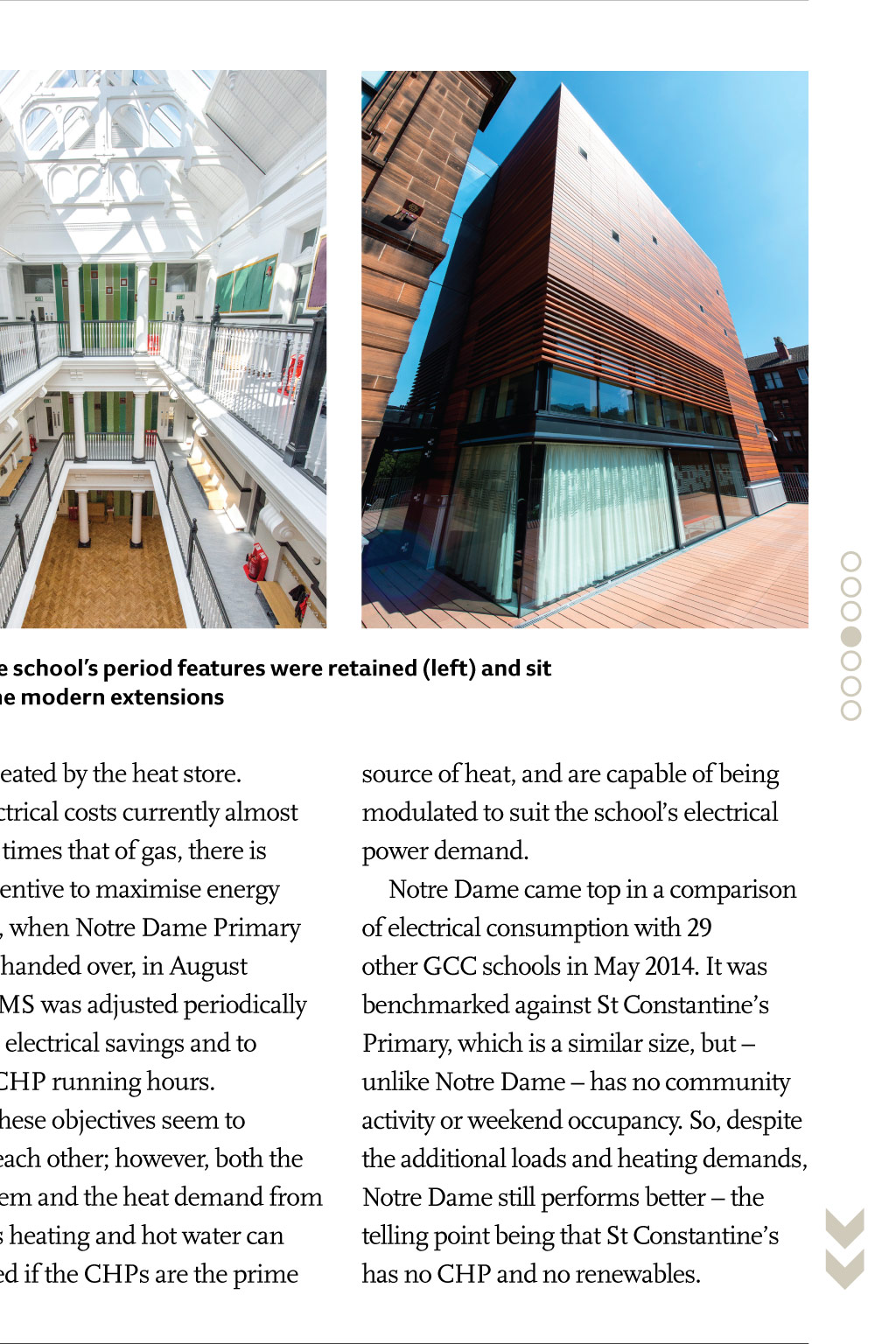

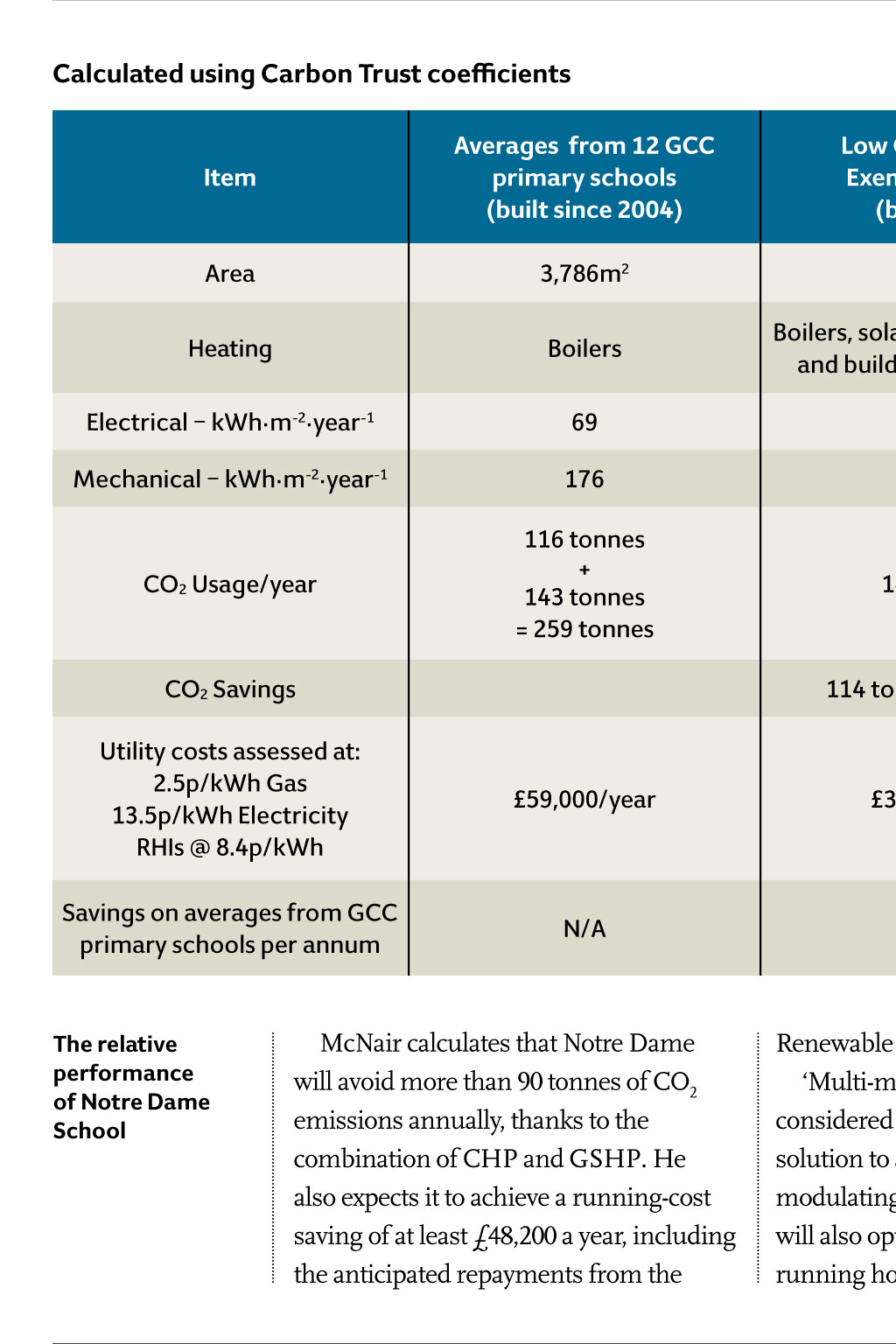

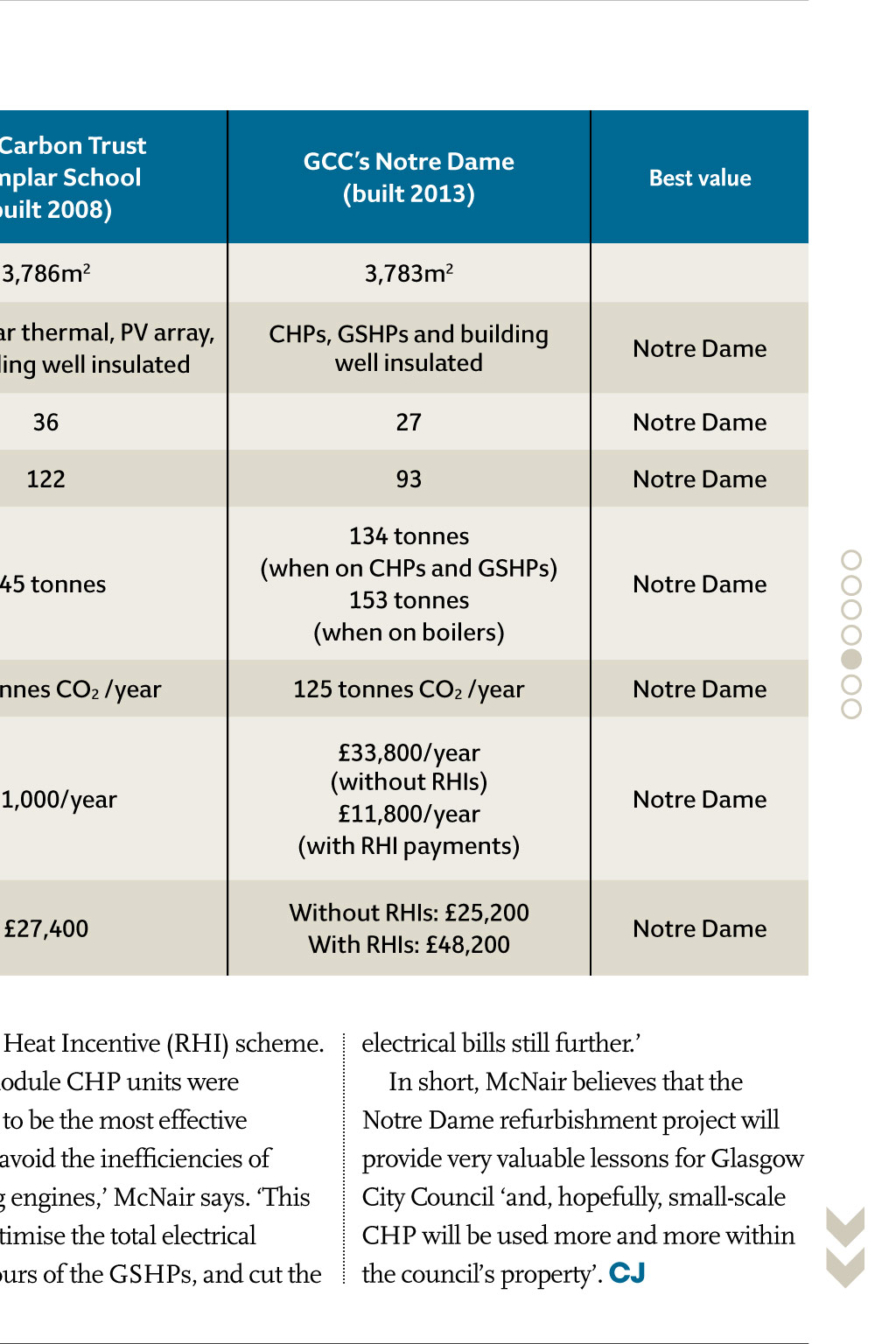

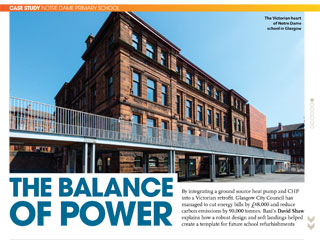

Case study notre dame primary school the victorian heart of notre Dame school in Glasgow The BalanCe oF PoWer T he refurbishment and re-engineering work at Notre Dame Primary school, in Glasgow, has produced a solution to a problem that has given many building services engineers sleepless nights: how to get ground source heat pumps (GSHPs) and CHP to work together effectively. Both are highly effective carbon-saving technologies, but they are not always good bedfellows, because they each need sizeable heat demand to operate at their best. Criticism of GSHPs has been increasing because many have had operating problems in the UK often due to inappropriate specification or poor installation. In some cases, wrongly sized heat pumps have frozen the ground as they try to extract too much energy in an incautious attempt to meet the heat demand from a building. By solving two problems at once getting the best out of GSHP technology and marrying it successfully with CHP Glasgow City Council (GCC) has created a design model for the rest of the industry to follow, and produced some impressive energy cost savings and cuts in carbon emissions. Built in 1894, the schools original Victorian building is still very much at By integrating a ground source heat pump and CHP into a Victorian retrofit, Glasgow City Council has managed to cut energy bills by 48,000 and reduce carbon emissions by 90,000 tonnes. Baxis David Shaw explains how a robust design and soft landings helped create a template for future school refurbishments the basement of the building to the classrooms, as part of a downdraught ventilation system. This approach was subsequently discredited because of its detrimental impact on childrens health, and a single-pipe heating system with cast-iron Princess column radiators was introduced before World War II. A major part of the recent refurbishment focused on reducing the schools carbon footprint, and GCCs engineering department took the opportunity of installing and test a combination of low carbon technologies. The aim of the project was to create a model that all future schools in Glasgow could seek to emulate, in terms of carbon reduction and electricity costs, says Bob McNair, lead mechanical engineer on the project, and a member of the councils development and regeneration team. The old building was gutted and rebuilt. The best architectural features were kept and restored, including the original Princess cast-iron radiators, which were rebuilt and pressure tested to 6 bar before being placed back into the refurbished building. Underfloor heating was chosen to optimise space, and is used in the main dining room, the gym, and the large nursery. The operating temperature of the heart of the school complex, which is after extensive refurbishment and the addition of a five-storey extension now home to Notre Dame, St Peters primary and the former Anderson Street Nursery, renamed Elie Street Nursery. Up to the 1930s, the building was heated by ducted warm air fed by a steam-driven air pump, after external air was drawn in through furnace coils. The warm air was then pumped from Five Dachs mini-CHP units were commissioned for notre Dames upgrade the school heating system is 45C, and lends itself to underfloor heating and low surface temperatures for the radiators, which makes them safe for the children. The carbon footprint is lowered by using GSHPs, while electricity bills are considerably reduced by CHP, compared to the more conventional approach of making gas boilers the lead heating technology. Five Dachs mini-CHP units, supplied and commissioned by Baxi Commercial Division, were specified as part of the upgrade. These are controlled in two banks one of three units and one of two. They produce 27.5kW of electricity during the day (16.5kW at night) to satisfy the requirements of the school buildings. The Dachs CHP array operates as the lead heat source, in tandem with the Ciat GSHPs. Modulating gas boilers act as backup and, so far, have only been required during the very coldest months. There are three heating modes: summer, winter and holiday, with the winter mode using the standby boilers as the main source of heat. The full CHP array is worked very hard during the winter months, but even at times of low heat demand for example, in summer it continues to operate, and any heat not required for hot water is The CHP is monitored remotely by Baxi via a modem link installed in the plantroom, and the operating data is shared with McNair so he can fine-tune the system equipment in the old plantroom. Mechanical ventilation has had to be fitted in the classrooms, even though they retained the high ceilings, because restrictions placed on the design by Historic Scotland would not permit natural ventilation ducts to penetrate the roof spaces. Again, however, McNair innovated; he used mechanical ventilation to boost the thermal output of the cast-iron radiators, with tempered air supplied from heat recovery units, installed in the attic, between the columns of the radiators. This effectively supplements the reduced output from the radiators due to the reduction in mean temperature (75oC to 40oC). The use of mechanical ventilation also satisfies the requirements of the advisory Building Bulletins on the design of classroom ventilation. A 5,000-litre heat store, which can accept hot water from any of the three heat sources, helps to keep the array running smoothly. This means long running hours for the CHP and a generous supply of free electricity as a result. The loading and unloading of the heat store was modelled to ensure the CHPs could easily charge and discharge the tank during most of the working year. The gas fuelled domestic hot water heater diverted to replenish the GSHP system. The combined running hours of the CHP compensate for the high maximum electrical loads from the GSHPs and their borehole pump (90.5kW). In practice, the high electrical load seldom occurs because the Ciat GSHPs come on in four stages, depending on demand. The GSHPs are only enabled by the BMS, so their on-board controls are able to manage the running of the scroll compressors. The GSHP draws its energy from 100m-deep boreholes and, by replenishing these, the CHP ensures there is a steady supply of heat during times of high demand. The CHP is monitored remotely by Baxi via a modem link installed in the plantroom, and the operating data is shared with McNair so he can fine-tune the system for example, to make sure the boilers dont kick in too early, which would take the heat demand away from the CHP and the renewables. The old, external plantroom was reused for the CHP, boilers and an gasfired storage water heater, with another small room built for the GSHPs and the heating pumps. This separation is important because it removes the hydrocarbon fire risk from the gas-fired Many of the schools period features were retained (left) and sit well with the modern extensions is also preheated by the heat store. With electrical costs currently almost four or five times that of gas, there is a major incentive to maximise energy savings. So, when Notre Dame Primary school was handed over, in August 2013, the BMS was adjusted periodically to optimise electrical savings and to maximise CHP running hours. At first, these objectives seem to contradict each other; however, both the GSHP system and the heat demand from the schools heating and hot water can be optimised if the CHPs are the prime source of heat, and are capable of being modulated to suit the schools electrical power demand. Notre Dame came top in a comparison of electrical consumption with 29 other GCC schools in May 2014. It was benchmarked against St Constantines Primary, which is a similar size, but unlike Notre Dame has no community activity or weekend occupancy. So, despite the additional loads and heating demands, Notre Dame still performs better the telling point being that St Constantines has no CHP and no renewables. Calculated using Carbon Trust coefficients Item Averages from 12 GCC primary schools (built since 2004) Low Carbon Trust ExemplarSchool (built 2008) GCCs notre Dame (built 2013) Area 3,786m2 3,786m2 3,783m2 Heating Boilers Boilers, solar thermal, PV array, and building well insulated CHPs, GSHPs and building well insulated Notre Dame Electrical kWhm-2year-1 69 36 27 Notre Dame Mechanical kWhm-2year-1 176 122 93 Notre Dame CO2 Usage/year 116 tonnes + 143 tonnes = 259 tonnes 145 tonnes 134 tonnes (when on CHPs and GSHPs) 153 tonnes (when on boilers) Notre Dame 114 tonnes CO2 /year 125 tonnes CO2 /year Notre Dame 31,000/year 33,800/year (without RHIs) 11,800/year (with RHI payments) Notre Dame 27,400 Without RHIs: 25,200 With RHIs: 48,200 Notre Dame CO2 Savings Utility costs assessed at: 2.5p/kWh Gas 13.5p/kWh Electricity RHIs @ 8.4p/kWh Savings on averages from GCC primary schools per annum The relative performance of notre Dame School 59,000/year N/A McNair calculates that Notre Dame will avoid more than 90 tonnes of CO2 emissions annually, thanks to the combination of CHP and GSHP. He also expects it to achieve a running-cost saving of at least 48,200 a year, including the anticipated repayments from the Renewable Heat Incentive (RHI) scheme. Multi-module CHP units were considered to be the most effective solution to avoid the inefficiencies of modulating engines, McNair says. This will also optimise the total electrical running hours of the GSHPs, and cut the Best value electrical bills still further. In short, McNair believes that the Notre Dame refurbishment project will provide very valuable lessons for Glasgow City Council and, hopefully, small-scale CHP will be used more and more within the councils property. CJ Putting the heat on ChP Planners and building regulations are driving the uptake of small-scale CHP, but there is a risk that performance will fall short if they are not properly specified and monitored. David Shaw, business development manager for Baxi-SenerTec UK, offers advice on optimising CHP The widespread uptake of in-building, small-scale combined heat and power (CHP) up to 50kW electrical output is being driven by Building Regulations Part L and local authority planning requirements. However, it is unethical to specify CHP to gain planning permission if the heat it produces is not required. Dumping waste heat is happening in far too many projects, which means CHP is not always generating the savings of which it is capable. It is crucial for CHP to be sized properly because, to deliver the maximum return, it must be running for the highest possible number of hours, so that it generates as much electricity as possible. According to Building Regulations, CHP must be sized to provide not less than 45% of the annual total heating to meet peak demand, and then add an additional percentage of capacity to allow for exceptional circumstances, which, in all probability, will never occur. This is catastrophic for CHP, as it means the system will be grossly oversized. Design engineers must ensure the CHP is sized to deliver the base load of the building, with boilers acting as backup to cover peak periods. There is no feed-in tariff for exporting CHP-generated electricity to the grid, so the system must ensure all the electricity produced is used inside the building. This is only possible if the person designing the system and commissioning the CHP understands how the building is to be used. An early conversation with the controls engineer, to make sure the BMS is set up with CHP in mind, is also crucial. CIBSEs AM12 Combined heat and power for buildings urges designers to seek the advice of CHP suppliers at an early stage of the design. Otherwise, the CHP specialist wont know how the building is going to be used, and what the appropriate solution should be. At Notre Dame Primary school, in Glasgow, the CHP works hard even during the summer months, because the heat it produces is diverted into the ground to replenish the energy source for the ground source heat pump system. This was only possible because the CHP team worked closely with the renewables engineers from the outset. One way of making sure the CHP is working hard is to install a buffer vessel. By diverting heat that would otherwise not be used into a large water store, the design team can ensure the CHP continues to run and the hot water is stored, to be drawn off for use in the building when required. CHP must be sized properly to deliver maximum returns CHP must be the lead heat generator so that all of the heat and electricity it produces is used in the building Financial grants Many clients can claim an Enhanced Capital Allowance (ECA) if the CHP they buy and install meets the requirements of the CHP Quality Assurance (CHPQA) scheme. In order to do this, the installation has to show that it is achieving a minimum Quality Index (QI) an indicator of energy efficiency and environmental performance. This, in turn, ensures that performance goals are reached and a good return on investment is delivered for the end user. The Building Regulations require that CHP plant in new and existing buildings should have a minimum CHPQA QI of 105, and power efficiency greater than 20% under annual operation. An engineer with CHP expertise should remain involved well beyond handover to ensure the system continues to deliver. Baxi-SenerTec supplies its Dachs CHP engines with a demand which includes space heating and domestic hot water unless there are overriding practical or economic constraints. Accurately calculating the performance of a building over the year is critical to ensure sufficient running hours can be achieved to meet the annual heat requirement. In too many cases, the CHP ends up oversized for summertime loads, resulting in either non-operation of the CHP, or the heat produced being dumped to ensure it carries on generating electricity. CHP must be the lead heat generator so that all of the heat and electricity it produces is used in the building. The cardinal sin is to design for peak demand with a bit extra for luck a nasty habit of heating system designers, who calculate the heat demand from the building, size the equipment modem, so the system can be monitored remotely and data shared with the building operator, to help them improve performance and meet running-cost goals. This helps prove an installation continues to meet QA standards. It also gives the team an opportunity to measure the spark gap, an assessment of the economic benefit of CHP. We continually look at the price of generating heat and electricity using CHP on site and compare it with the cost of generating it separately through conventional means for example, gas-fired boilers and grid-sourced electricity. The design team must factor the spark gap into their calculations. In the end, it comes back to good, sound engineering and establishing an accurate heat-load profile for the building, so you know how much electricity the CHP will generate. CJ