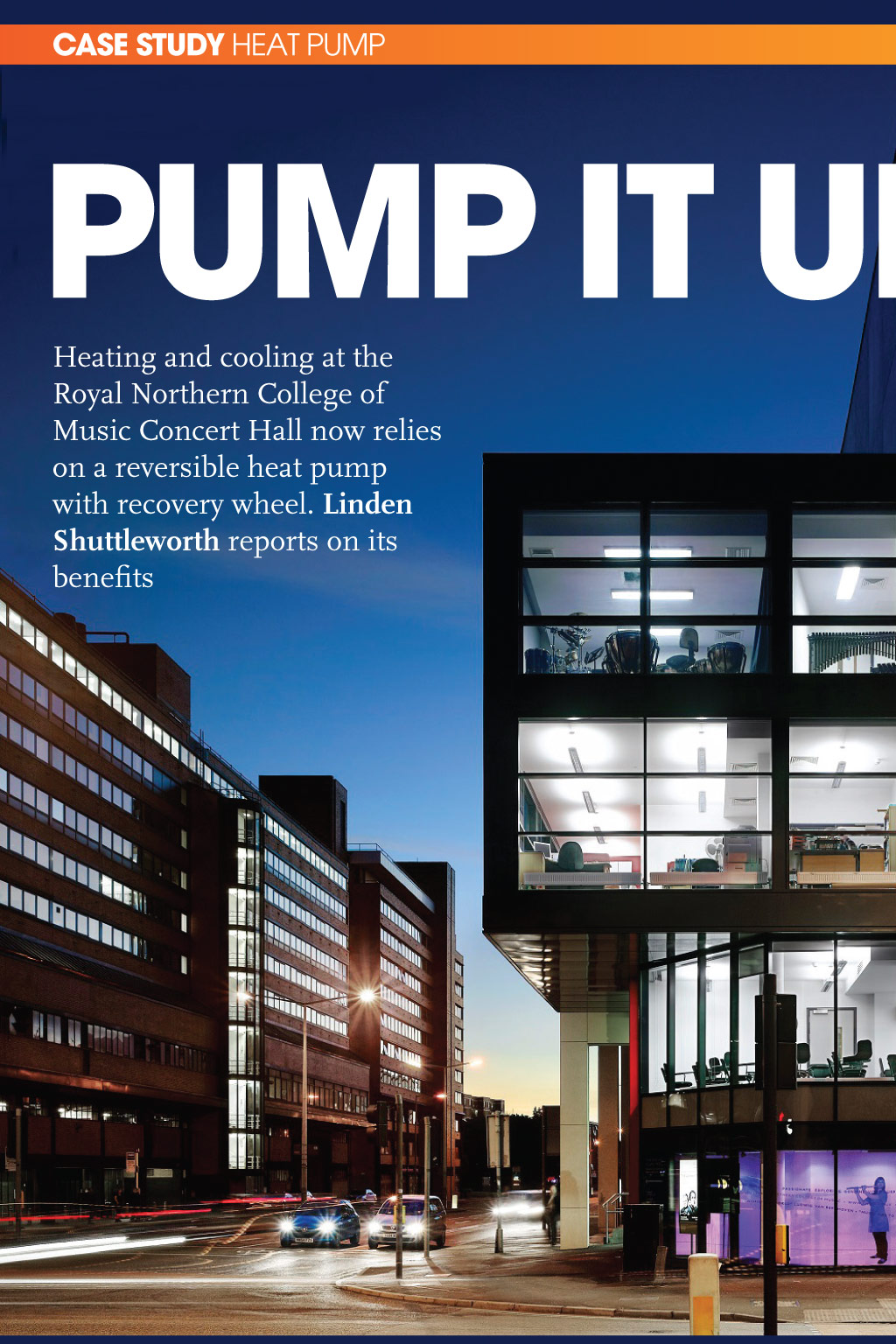

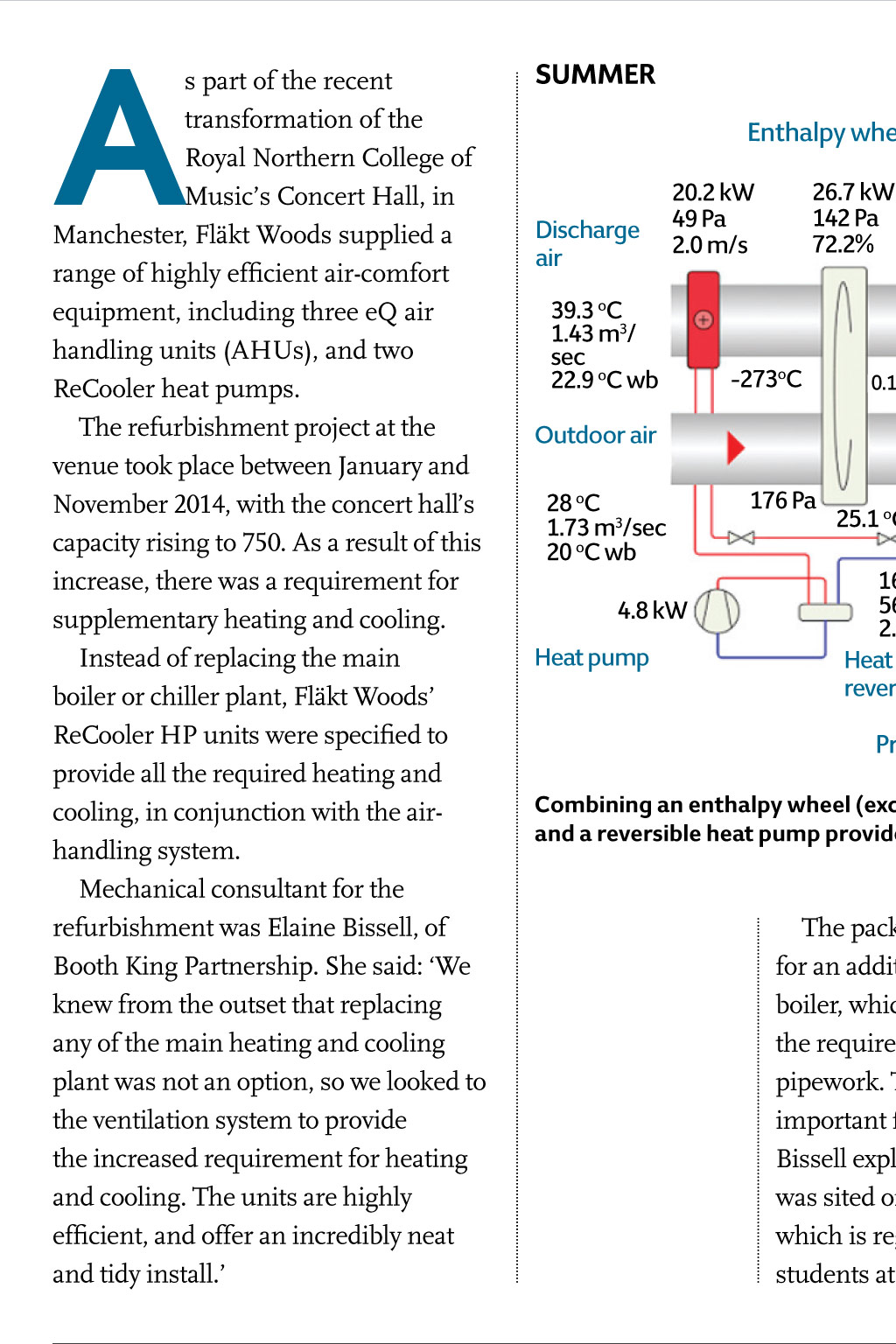

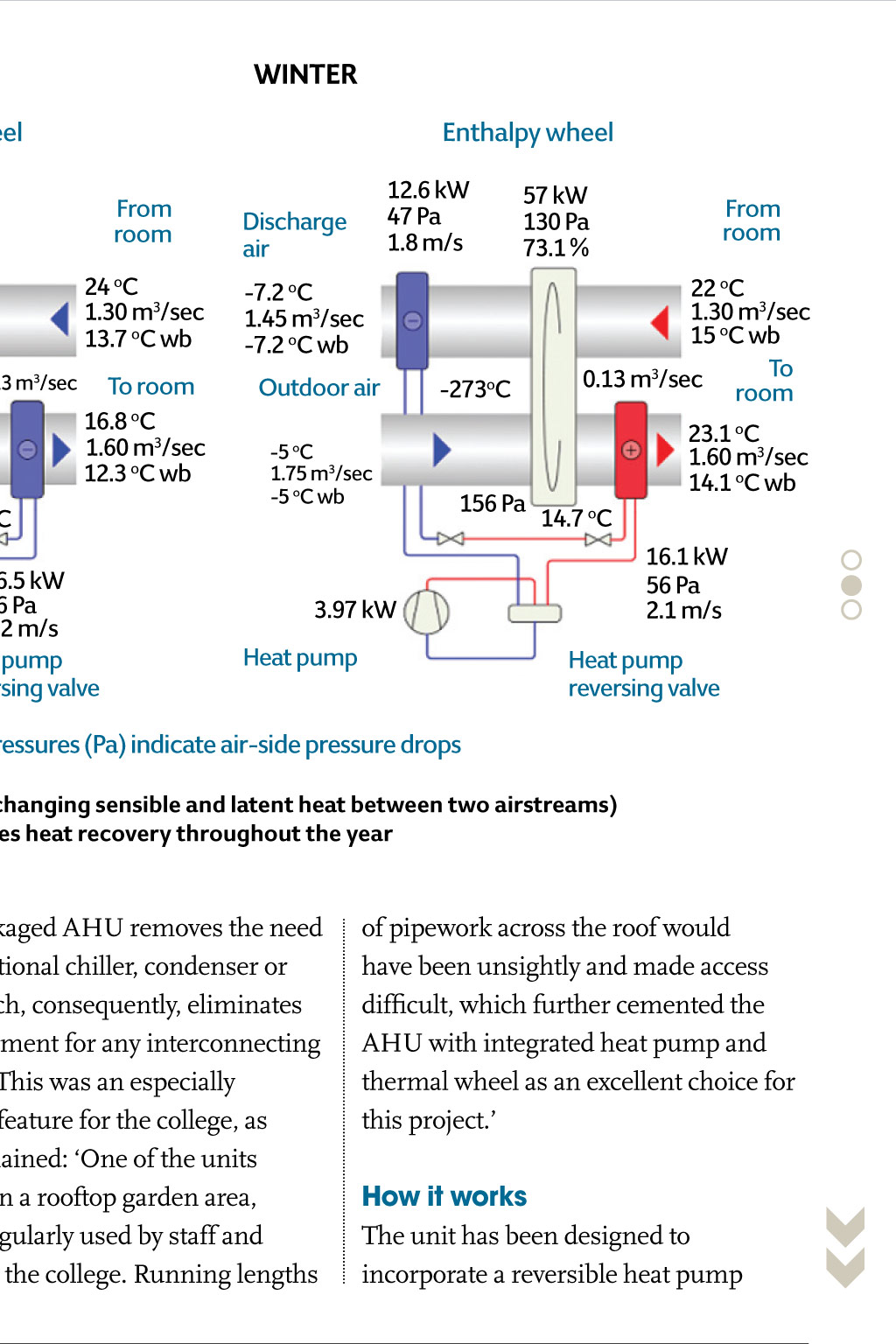

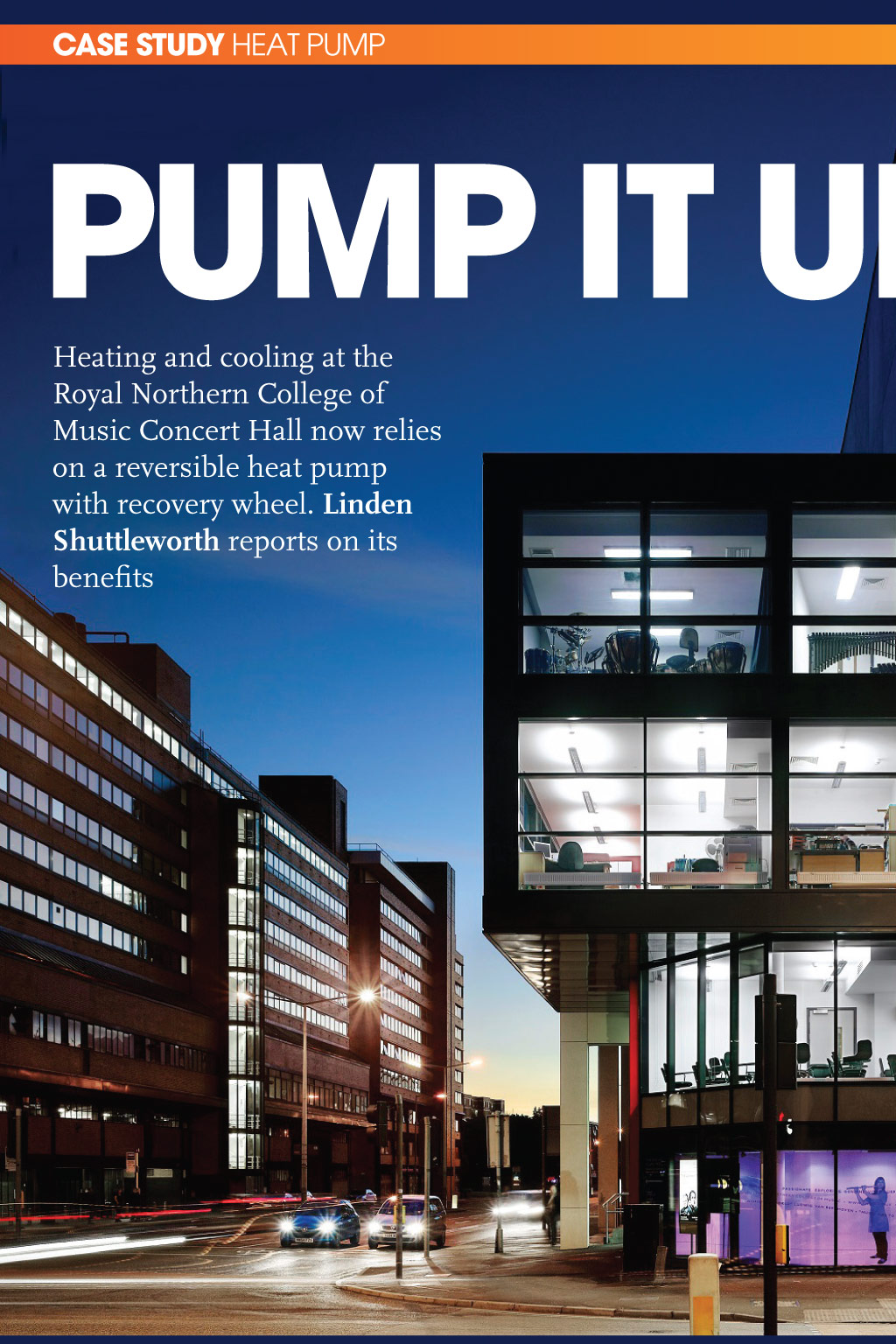

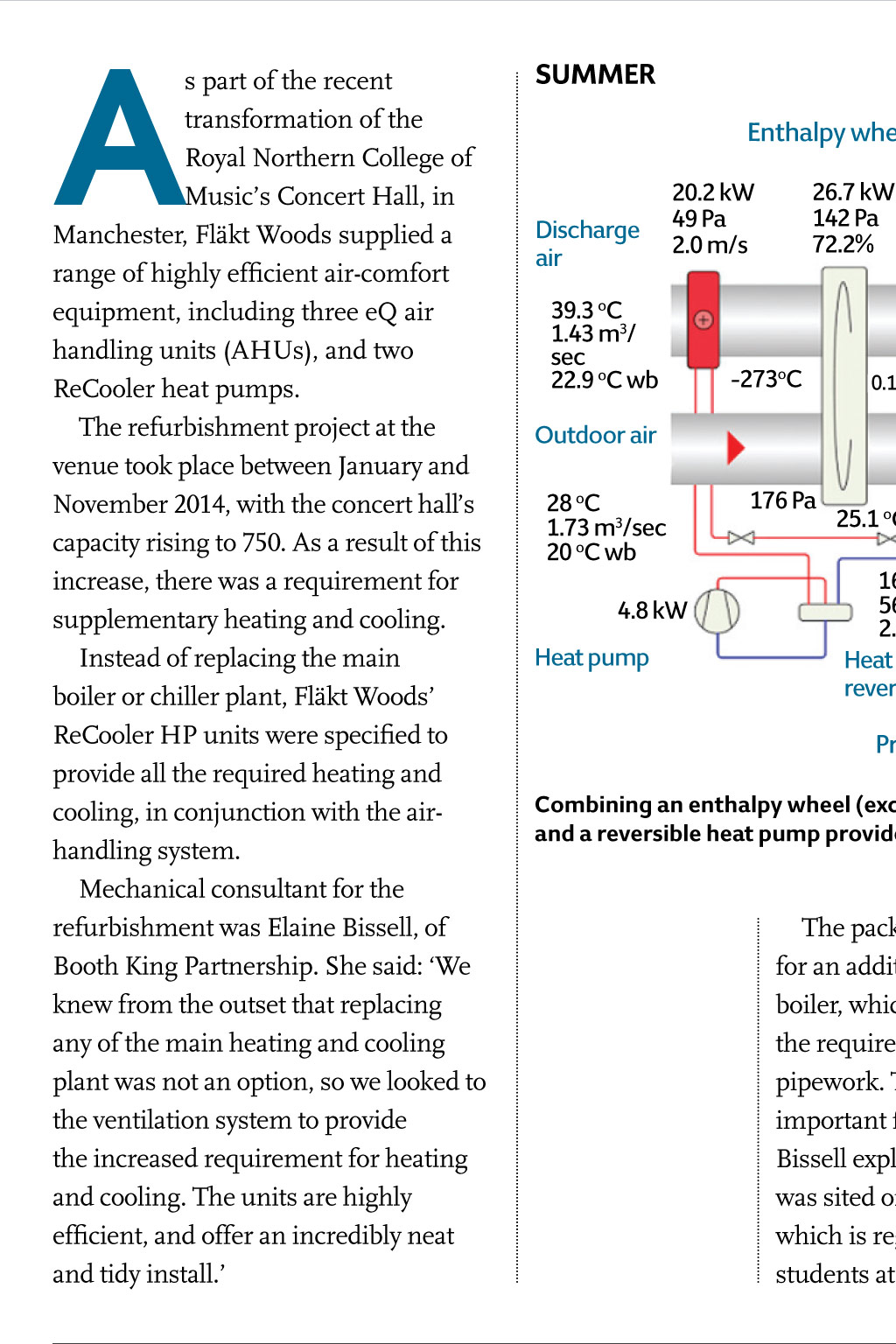

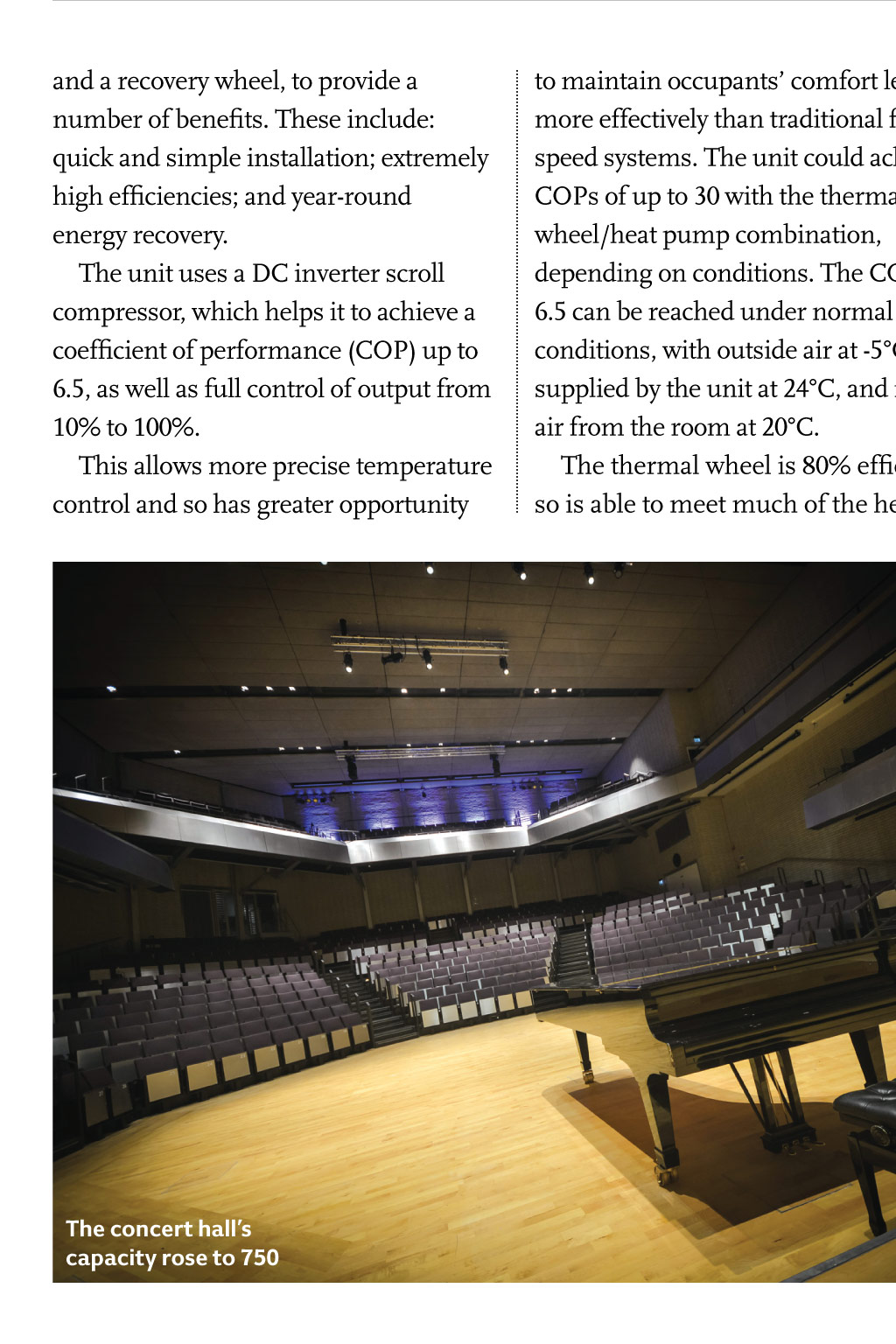

Case study heat pump pump it up heating and cooling at the royal Northern College of Music Concert Hall now relies on a reversible heat pump with recovery wheel. Linden Shuttleworth reports on its benefits A s part of the recent transformation of the Royal Northern College of Musics Concert Hall, in Manchester, Flkt Woods supplied a range of highly efficient air-comfort equipment, including three eQ air handling units (AHUs), and two ReCooler heat pumps. The refurbishment project at the venue took place between January and November 2014, with the concert halls capacity rising to 750. As a result of this increase, there was a requirement for supplementary heating and cooling. Instead of replacing the main boiler or chiller plant, Flkt Woods ReCooler HP units were specified to provide all the required heating and cooling, in conjunction with the airhandling system. Mechanical consultant for the refurbishment was Elaine Bissell, of Booth King Partnership. She said: We knew from the outset that replacing any of the main heating and cooling plant was not an option, so we looked to the ventilation system to provide the increased requirement for heating and cooling. The units are highly efficient, and offer an incredibly neat and tidy install. and a recovery wheel, to provide a number of benefits. These include: quick and simple installation; extremely high efficiencies; and year-round energy recovery. The unit uses a DC inverter scroll compressor, which helps it to achieve a coefficient of performance (COP) up to 6.5, as well as full control of output from 10% to 100%. This allows more precise temperature control and so has greater opportunity The concert halls capacity rose to 750 SUMMER WInTER Enthalpy wheel Discharge air 26.7 kW 142 Pa 72.2% 20.2 kW 49 Pa 2.0 m/s 39.3 oC 1.43 m3/ sec 22.9 oC wb 4.8 kW Heat pump From room 24 oC 1.30 m3/sec 13.7 oC wb -273oC 0.13 m3/sec Outdoor air 28 oC 1.73 m3/sec 20 oC wb Enthalpy wheel 176 Pa To room 16.8 oC 1.60 m3/sec 12.3 oC wb 25.1 C o 16.5 kW 56 Pa 2.2 m/s Heat pump reversing valve 12.6 kW 47 Pa 1.8 m/s Discharge air 57 kW 130 Pa 73.1 % -7.2 oC 1.45 m3/sec -7.2 oC wb Outdoor air -273oC -5 oC 1.75 m3/sec -5 oC wb 156 Pa 22 oC 1.30 m3/sec 15 oC wb To 0.13 m3/sec room 23.1 oC 1.60 m3/sec 14.1 oC wb 14.7 oC 16.1 kW 56 Pa 2.1 m/s 3.97 kW Heat pump From room Heat pump reversing valve Pressures (Pa) indicate air-side pressure drops Combining an enthalpy wheel (exchanging sensible and latent heat between two airstreams) and a reversible heat pump provides heat recovery throughout the year The packaged AHU removes the need for an additional chiller, condenser or boiler, which, consequently, eliminates the requirement for any interconnecting pipework. This was an especially important feature for the college, as Bissell explained: One of the units was sited on a rooftop garden area, which is regularly used by staff and students at the college. Running lengths to maintain occupants comfort levels more effectively than traditional fixedspeed systems. The unit could achieve COPs of up to 30 with the thermal wheel/heat pump combination, depending on conditions. The COP of 6.5 can be reached under normal UK conditions, with outside air at -5C, air supplied by the unit at 24C, and return air from the room at 20C. The thermal wheel is 80% efficient, so is able to meet much of the heating of pipework across the roof would have been unsightly and made access difficult, which further cemented the AHU with integrated heat pump and thermal wheel as an excellent choice for this project. how it works The unit has been designed to incorporate a reversible heat pump demand for the concert hall before the heat pump is activated. The wheel is hygroscopic, giving both latent and sensible recovery. The manufacture estimates that using the AHU with integrated heat pump and thermal wheel reduces energy by 30% compared with traditional, non-electric heating and cooling systems. CJ LInDEn SHUTTLEWORTH is product sales manager for Flkt Woods UK